Additional electric arc heating copper backing board pre-heating aluminum alloy and magnesium alloy welding method

A welding method and arc heating technology, which is applied in the field of arc welding and welding, and can solve the problems that aluminum alloy and magnesium alloy are prone to produce pores and cracks, and the back of the joint is poorly formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

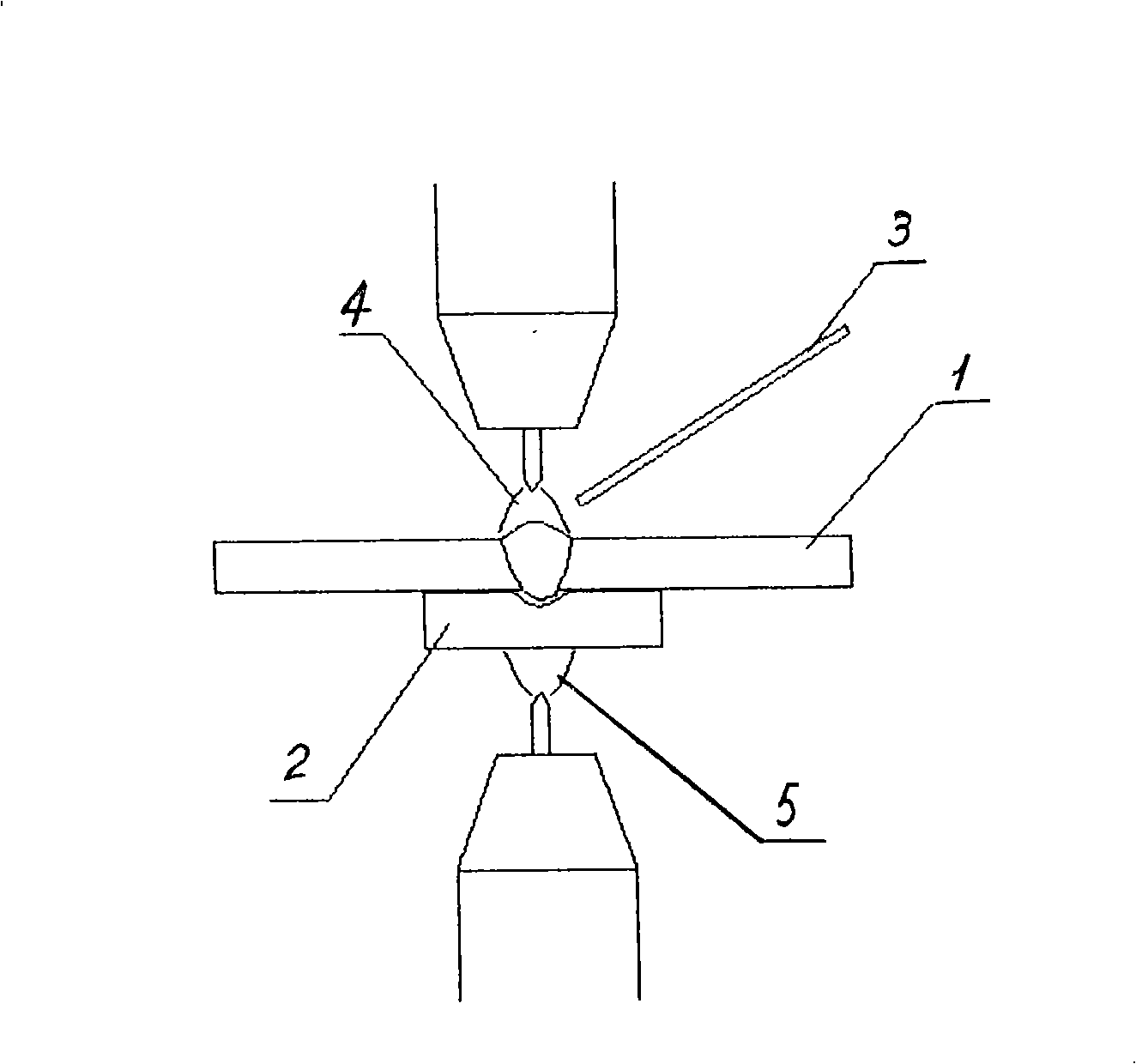

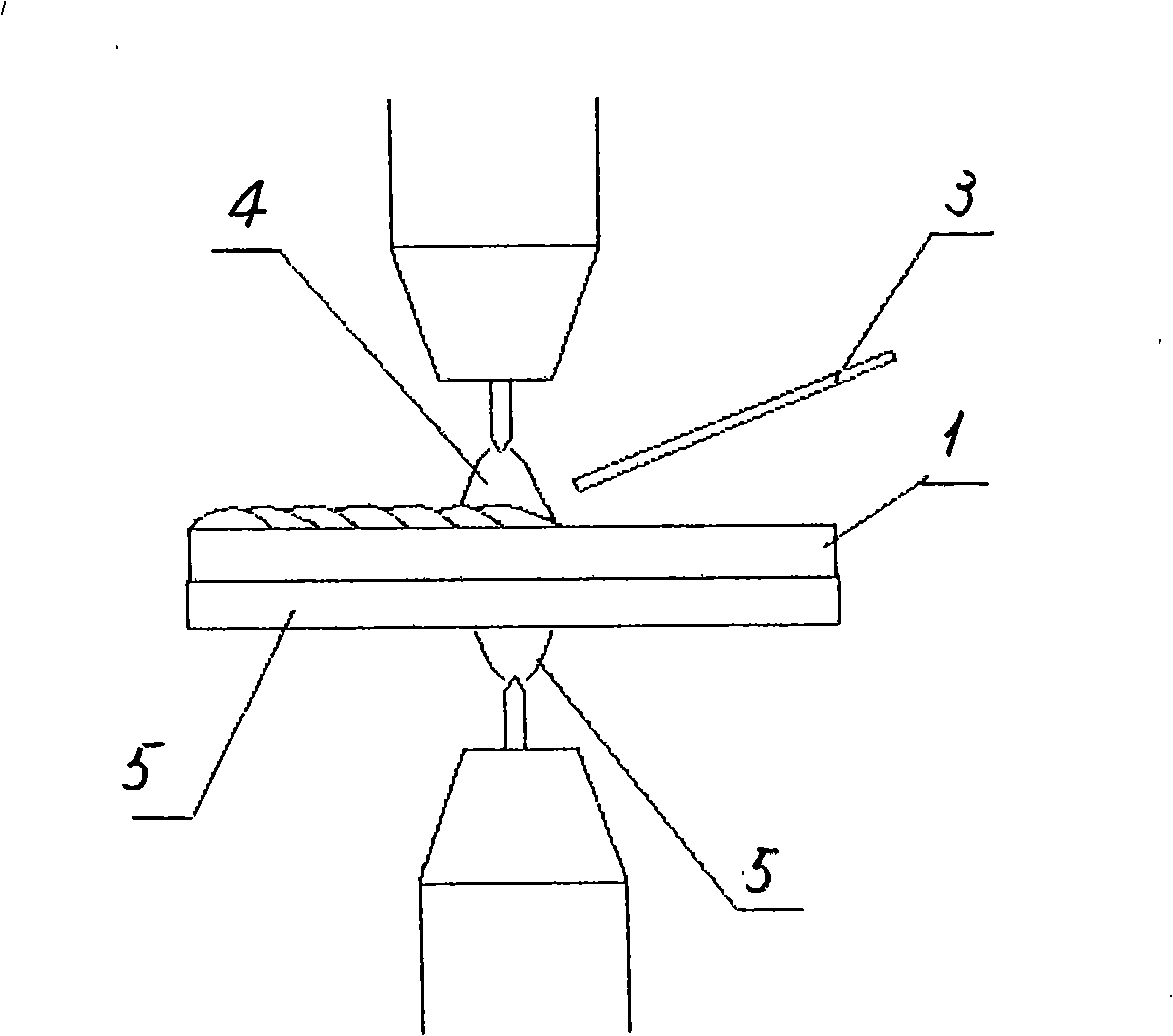

[0012] The welding method for preheating aluminum alloy and magnesium alloy with additional electric arc heating copper backing plate of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] In the method, a copper backing plate is used when welding aluminum alloy and magnesium alloy butt welds, and an electric arc is used to heat the back of the backing plate. The shape of the copper backing plate varies according to the weldment. When welding thin plates, flat copper backing plates can be used directly, such as image 3 ; When welding thicker plates, the shape of the copper backing plate adopts two forms: one is to use the rolling method to roll the thinner copper backing plate into Figure 4 The shape shown; the other is to use the method of machining to open a notch on the thicker copper backing plate, the shape is as follows Figure 5 shown. The welding method is TIG, MIG, plasma arc welding or laser welding. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com