Method for preparing battery cathode material calcium zincate and sealing device used for the same

A battery negative electrode and sealing device technology, which is applied to battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of not considering the solubility of ZnO, the uncertain ratio of added raw materials, and the inability to realize mother liquor circulation, etc., so as to achieve convenient operation costs Easy to operate, low cost, no pollution to the environment, and shortened drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

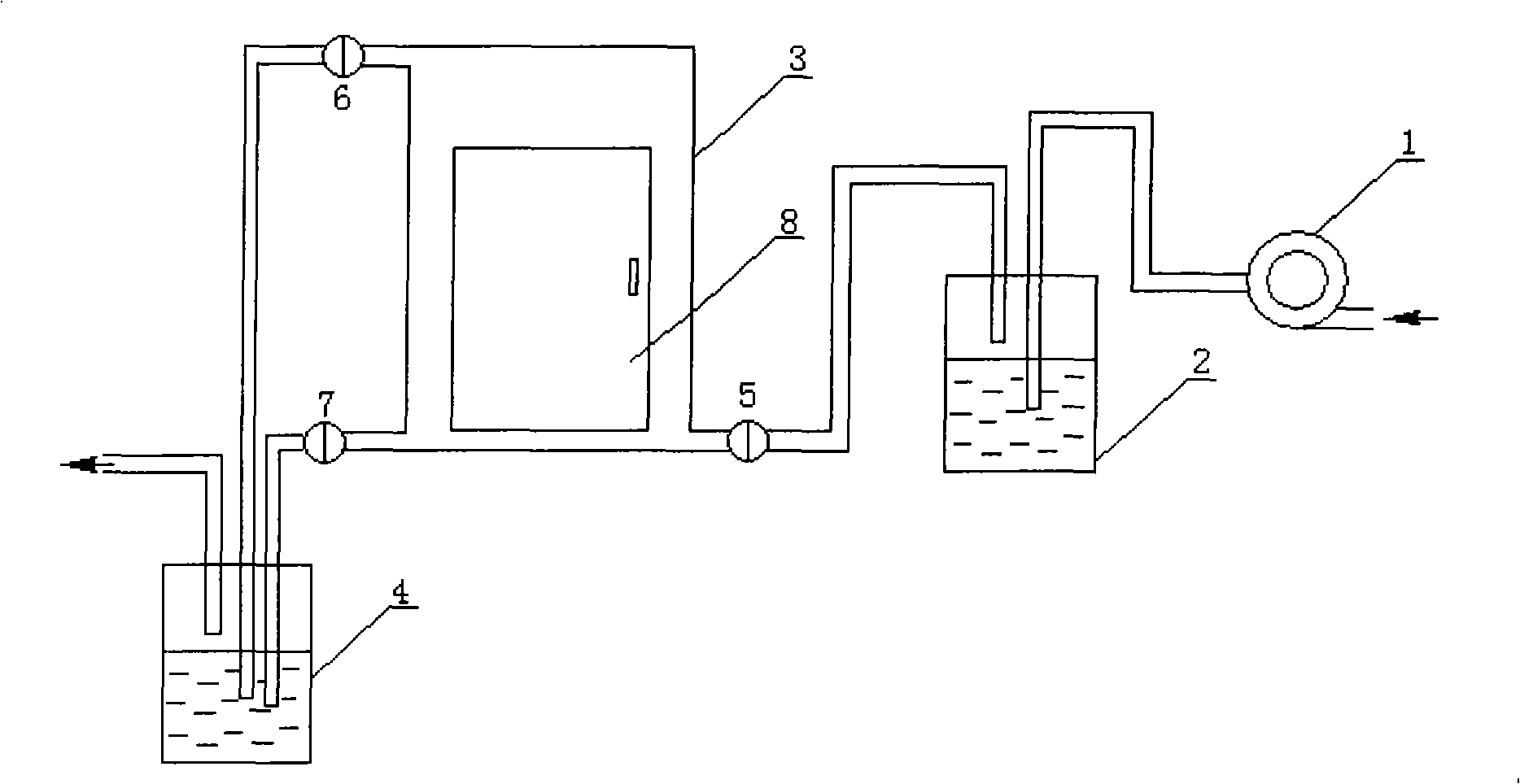

[0019] The preparation of zinc-nickel rechargeable battery negative electrode material calcium zincate comprises the following steps:

[0020] (1), there is a reaction vessel that can continuously stir in the sealed cavity 3, and ZnO and Ca(OH) 2 According to the molar ratio of 2:1, add it into the reaction container in the sealed cavity 3 containing NaOH solution, close the small door 8 of the sealed cavity 3, turn on the blower 1, and keep the reactants under continuous stirring at 55-95°C Down reaction 10~16 hours;

[0021] (2), the product after the reaction is directly carried out suction filtration once, the product after the suction filtration is washed once with dehydrated alcohol, then carries out the second suction filtration, the calcium zincate after the second suction filtration is at 20~100 Dry in a vacuum oven for 2 to 10 hours at ℃;

[0022] (3) reclaim the filtrate of suction filtration for the first time and recycle as the reaction medium, reclaim the absol...

Embodiment 1

[0029] Put 3.70 kilograms of calcium hydroxide powder and 8.15 kilograms of zinc oxide powder into the reaction vessel containing 5% NaOH mother liquor in the sealed cavity 3, close the small door 8 of the sealed cavity 3, and start the shielding gas device. React for 15 hours under constant stirring at 65°C, filter the reacted mixture directly, then add 10.0 kg of absolute ethanol to wash once, filter again, and dry in a vacuum oven at 80°C 5h. The desired product calcium zincate can be obtained.

Embodiment 2

[0031]Put 3.70 kilograms of calcium hydroxide powder and 8.15 kilograms of zinc oxide powder into the reaction vessel containing 10% NaOH mother liquor in the sealed cavity 3, close the small door 8 of the sealed cavity 3, and start the shielding gas device. React at 75°C for 10 hours under constant stirring, filter the reacted mixture directly, then add 10.0 g of absolute ethanol to wash once, and perform suction filtration again, then carry out in a vacuum oven at 20°C Dry for 10h. The desired product calcium zincate can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com