Method for synthesizing neotame

A technology of neotame and mixture, applied in the field of sweeteners, can solve the problems of complex process operation, unsuitable for industrialized production, high cost of neotame, and achieve the effects of reducing production cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

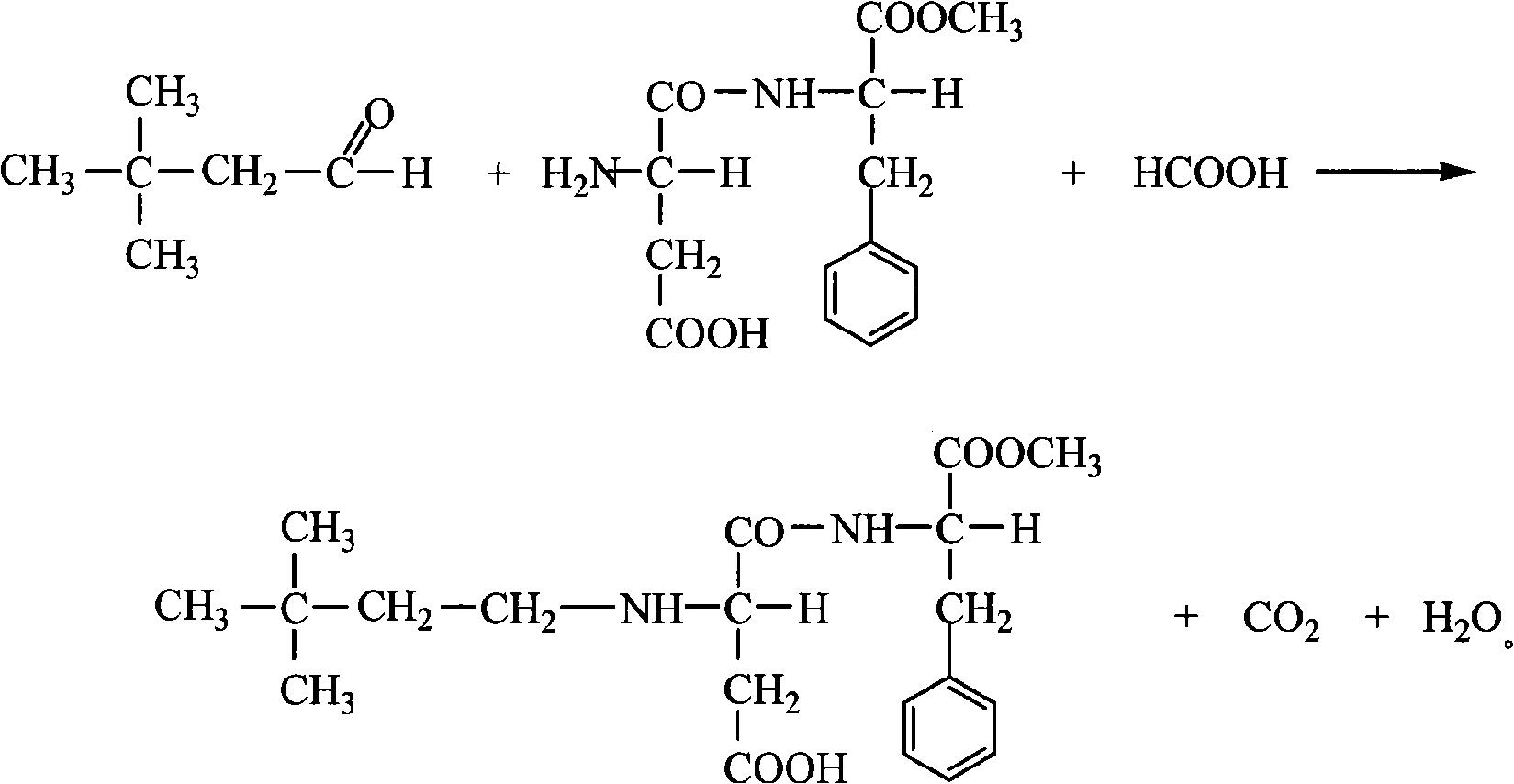

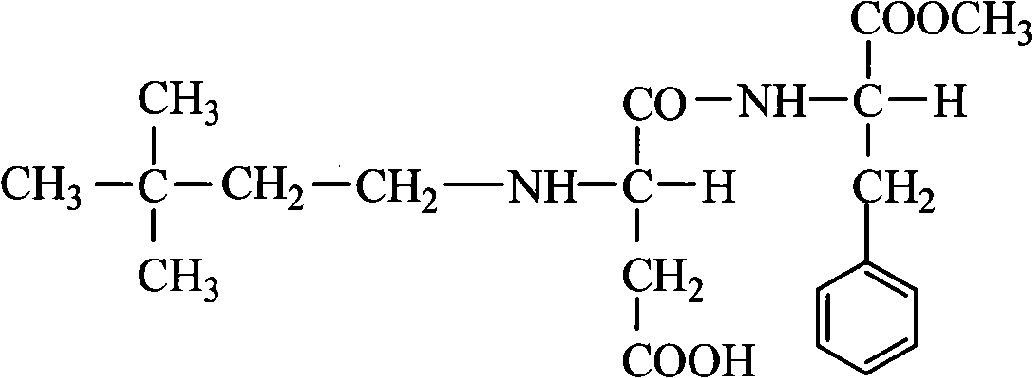

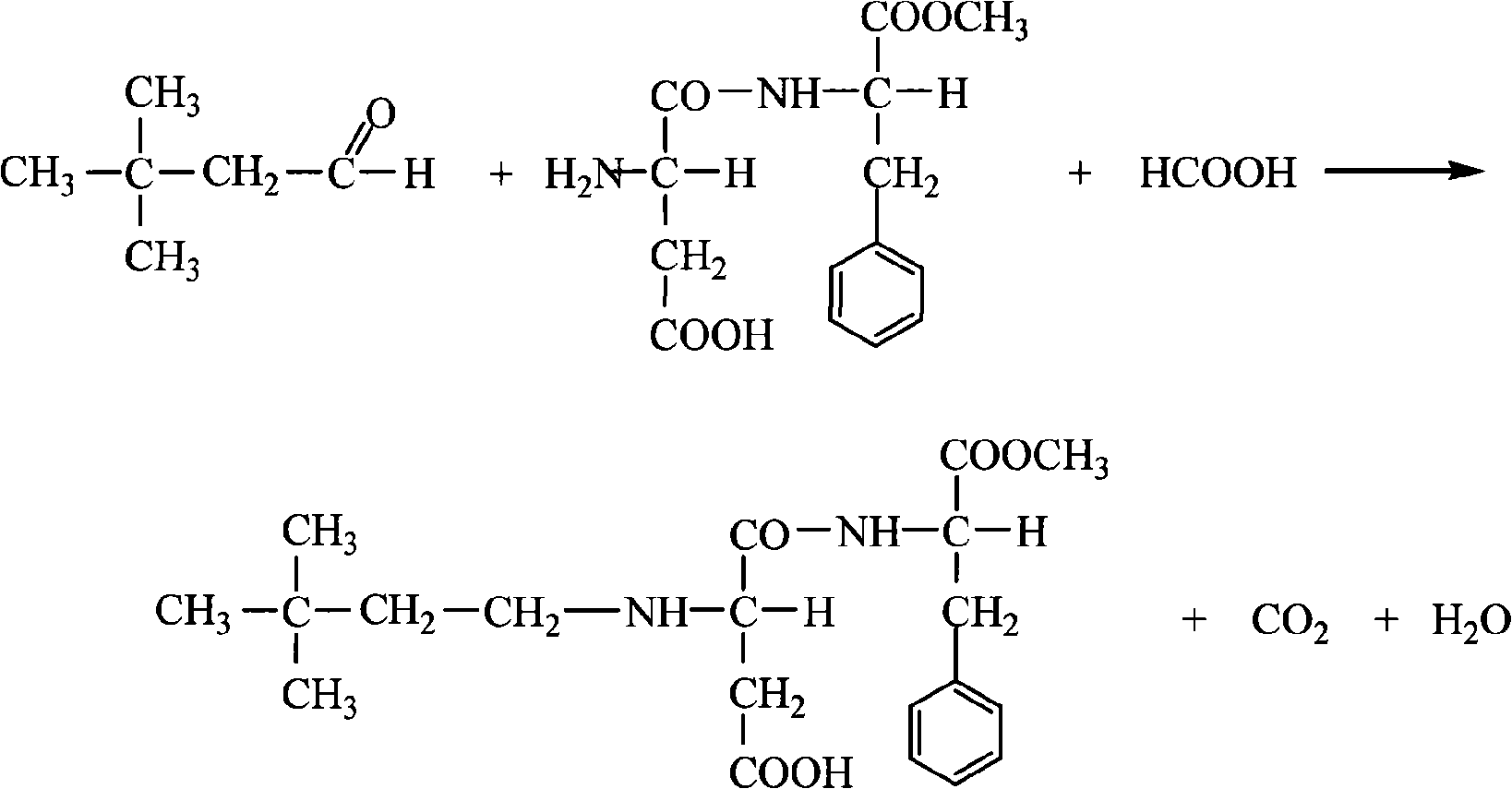

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: add 120g methanol in the 500ml four-neck flask that is placed in constant temperature water bath with electric stirrer, thermometer and reflux condenser, start stirring, add aspartame 29.43g ( 0.1 mol), 5.52 g (0.12 mol) of formic acid was added, the temperature was raised to 35° C., and 11 g (0.11 mol) of 3,3-dimethylbutyraldehyde was added. Keep the temperature at 35°C for 24h. Then use a rotary evaporator to concentrate under reduced pressure to a slurry, add 25 ml of ethanol aqueous solution with a concentration of 40% by mass, heat to dissolve, slowly cool to 0° C. overnight, and filter with suction. The filter cake was washed with 15ml of cold deionized water, filtered to dryness, and vacuum-dried at 40°C for 12 hours to obtain 23.08g of neotame product with a yield of 61% and a purity higher than 98%.

Embodiment 2

[0019] Embodiment 2: reaction device and operation method are the same as embodiment 1. The difference is that the reaction temperature is 45°C and the reaction time is 12h. As a result, 24.33 g of neotame product was obtained, the yield was 64.3%, and the purity was higher than 98%.

Embodiment 3

[0020] Embodiment 3: reaction apparatus and operation method are the same as embodiment 1. The difference is that the reaction temperature is 65°C and the reaction time is 8h. As a result, 22.86g of neotame product was obtained with a yield of 60.4% and a purity higher than 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com