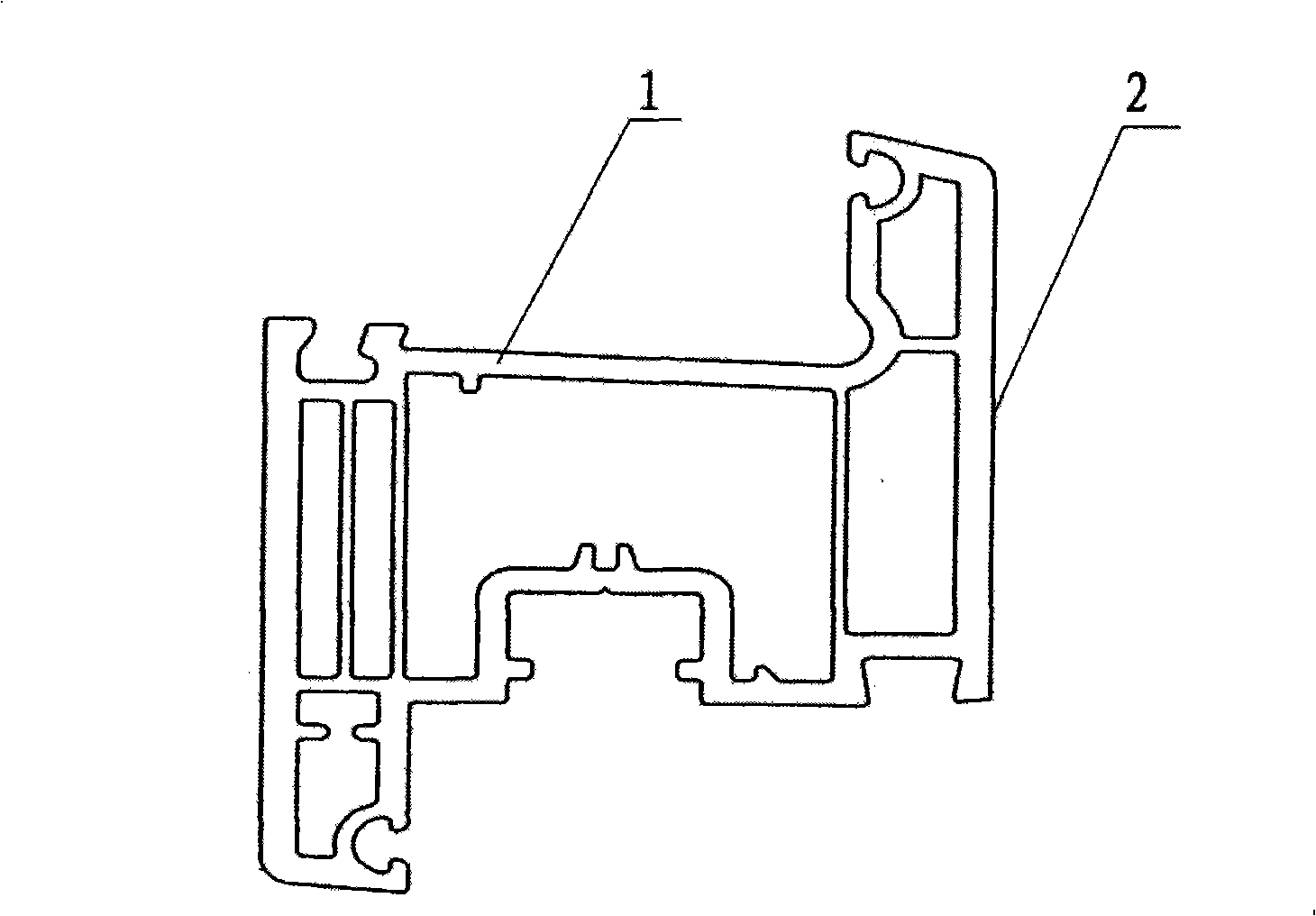

Window sectional material and method for manufacturing same

A profile and window technology, applied in the field of window profiles and its manufacturing, can solve the problems of wooden window frame texture gap, single color, cost increase, etc., to ensure structural strength and durability, high product qualification rate, and ensure structural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

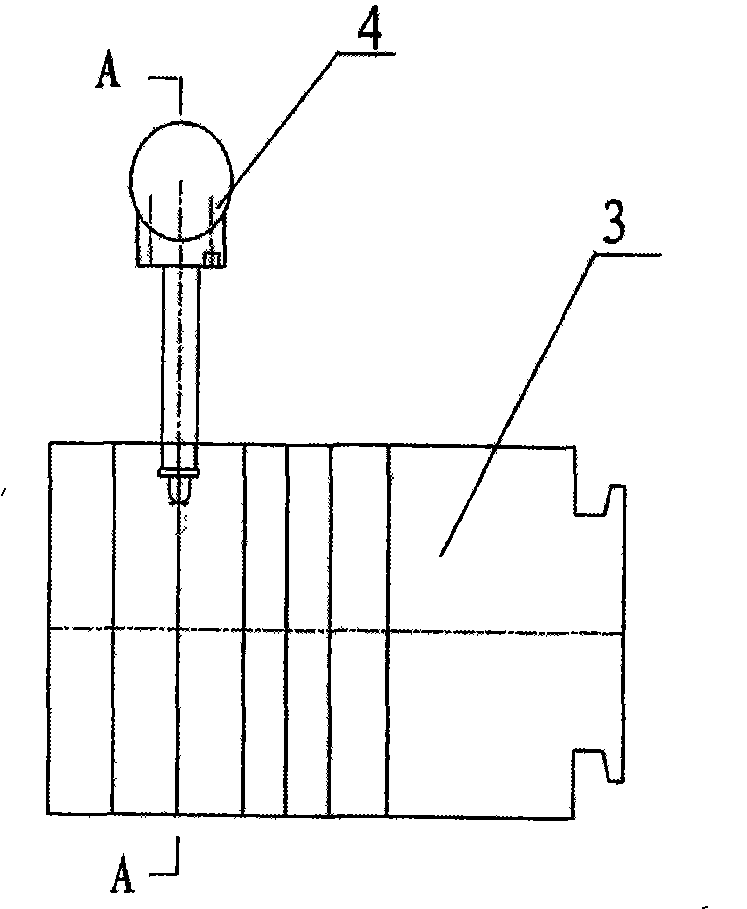

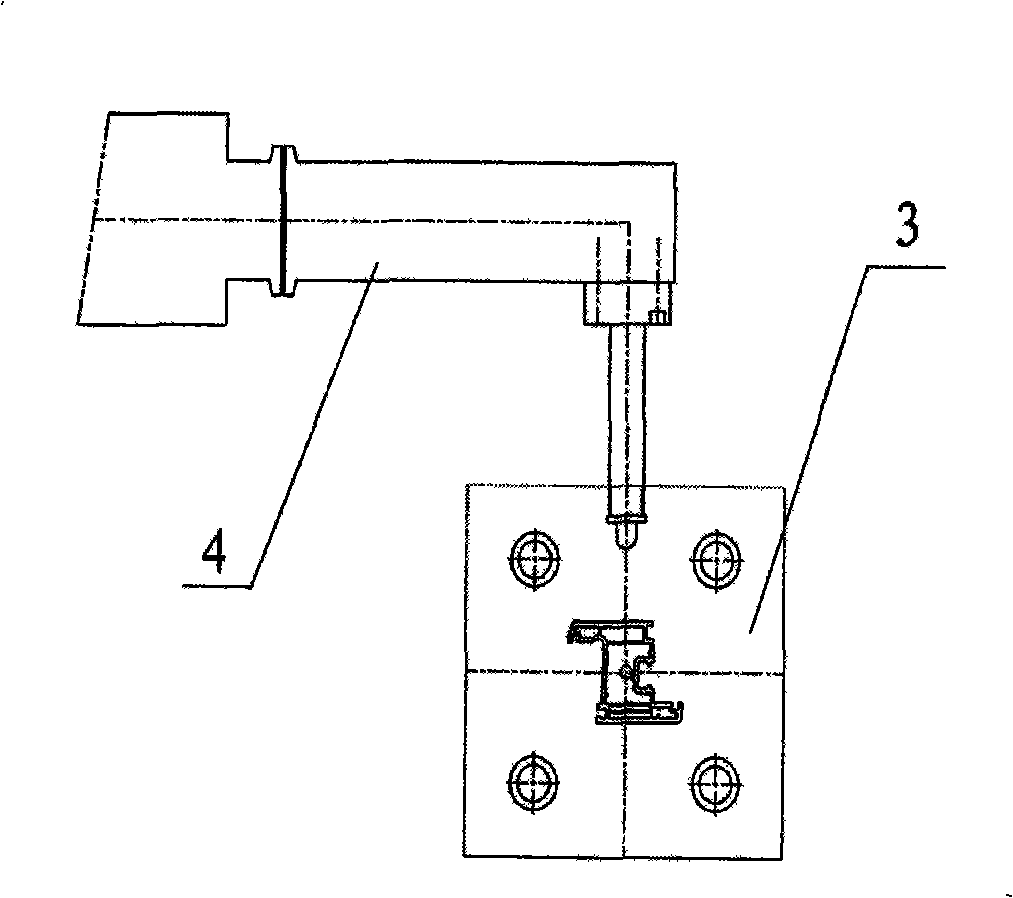

Method used

Image

Examples

Embodiment 1

[0033] Window profile of the present invention, the proportioning of its inner and outer layer materials is:

[0034] The main components of the inner material of the profile are in parts by weight:

[0035] 100 parts of PVC, 8 parts of polyvinyl chloride, 6 parts of compound stabilizer, compound stabilizer is stearic acid, ultraviolet absorber, dibasic lead stearate, dibasic lead phosphite, calcium stearate and paraffin Mixture, the weight ratio is: 10:1:12:70:20:1; 2 parts of acrylate; CaCO 3 5 copies;

[0036] The main components of the outer layer material are in parts by weight:

[0037] Excipients 1: 100 parts of PVC, 30 parts of wood powder passed through a 120-mesh sieve, 5.5 parts of composite stabilizer, the composite stabilizer is stearic acid, ultraviolet absorber (UV-531), dibasic lead stearate, dibasic The mixture of lead phosphite, calcium stearate and paraffin wax, its weight ratio is: 10:1:12:70:20:1; 0.8 parts of LIGA38, 7 parts of polyvinyl chloride, 2-3...

Embodiment 2

[0044] Window profile of the present invention, the proportioning of its inner and outer layer materials is:

[0045] The main components of the inner material of the profile are in parts by weight:

[0046] 100 parts of PV, 7 parts of polyvinyl chloride, 5.5 parts of compound stabilizer, compound stabilizer is stearic acid, ultraviolet absorber, dibasic lead stearate, dibasic lead phosphite, calcium stearate and paraffin The mixture, its weight ratio is: 10:1:12:70:20:1, 3 parts of acrylate;

[0047] The main components of the outer layer material are in parts by weight:

[0048] Excipient 1: 100 parts of PVC, 30 parts of wood powder passed through a 110 mesh sieve, 5 parts of composite stabilizer, the composite stabilizer is stearic acid, ultraviolet absorber (UV-326), dibasic lead stearate, dibasic The mixture of lead phosphite, calcium stearate and paraffin wax, its weight ratio is: 10:1:12:70:20:1; 381 parts of LIGA, 6 parts of polyvinyl chloride, 3 parts of rutile tita...

Embodiment 3

[0055] Window profile of the present invention, the proportioning of its inner and outer layer materials is:

[0056] The main components of the inner material of the profile are in parts by weight:

[0057] 100 parts of PVC, 6 parts of polyvinyl chloride, 6 parts of compound stabilizer, compound stabilizer is a mixture of stearic acid, ultraviolet absorber, dibasic lead stearate, dibasic lead phosphite and calcium stearate, Its weight ratio is: 10:1:12:70:20; 2.5 parts of acrylate;

[0058] The main components of the outer layer material are in parts by weight:

[0059] Excipient 1: 100 parts of PVC, 30 parts of rice husk powder passed through a 80-mesh sieve, 6 parts of composite stabilizer, the composite stabilizer is stearic acid, ultraviolet absorber (UV-3346), dibasic lead stearate, di-salt A mixture of basic lead phosphite and calcium stearate, the weight ratio of which is: 10:1:12:70:20; 1 part of KZTPP, 8 parts of polyvinyl chloride, and 2 parts of rutile titanium d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Overlap degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com