Method for removing fluoride in flue gas during smelting

A technology for smelting flue gas and fluoride, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as difficulty in adapting to the fluoride removal process, achieve high use value and promotion, prevent corrosion, and guarantee The effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

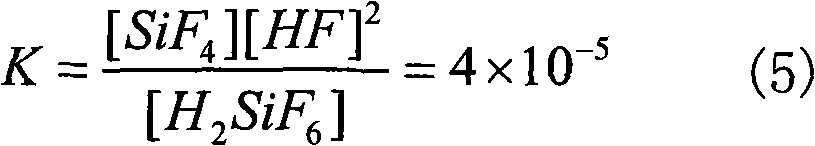

Method used

Image

Examples

Embodiment

[0036] Smelting flue gas volume is 210,000 Nm 3 / h, the fluoride concentration is 64.38mg / Nm 3 , the circulating acid discharge of the purification section of the acid system is 70m 3 / h. In order to reduce the fluoride content in the flue gas to below the standard, the "three-stage and four-layer fluoride removal" method is adopted while using the above-mentioned cycle acid discharge.

[0037] Select the water glass whose modulus is 2.6, select the addition amount of water glass as 4kg / h, and select the dilution ratio as 1:40. The water glass conveying pump pumps the water glass into the high level tank, and flows from the high level tank into the circulating acid of the turbulent tower and the washing tower. At the same time, adjust the return valve at the outlet of the water glass delivery pump to keep the liquid backflow, so as to promote the dissolution of the water glass.

[0038] Choose quartz stone with a particle size of 40-500mm, and stack it at the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com