Preparation for asparaginic acid protease inhibitors

A protease inhibitor, aspartic acid technology, applied in the field of fungal fermentation bioactive products, can solve the limitations; foreign countries have extracted aspartic acid from potatoes, tomatoes and legumes and other problems, reaching the high level of medicine Health care value, good application prospect, effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

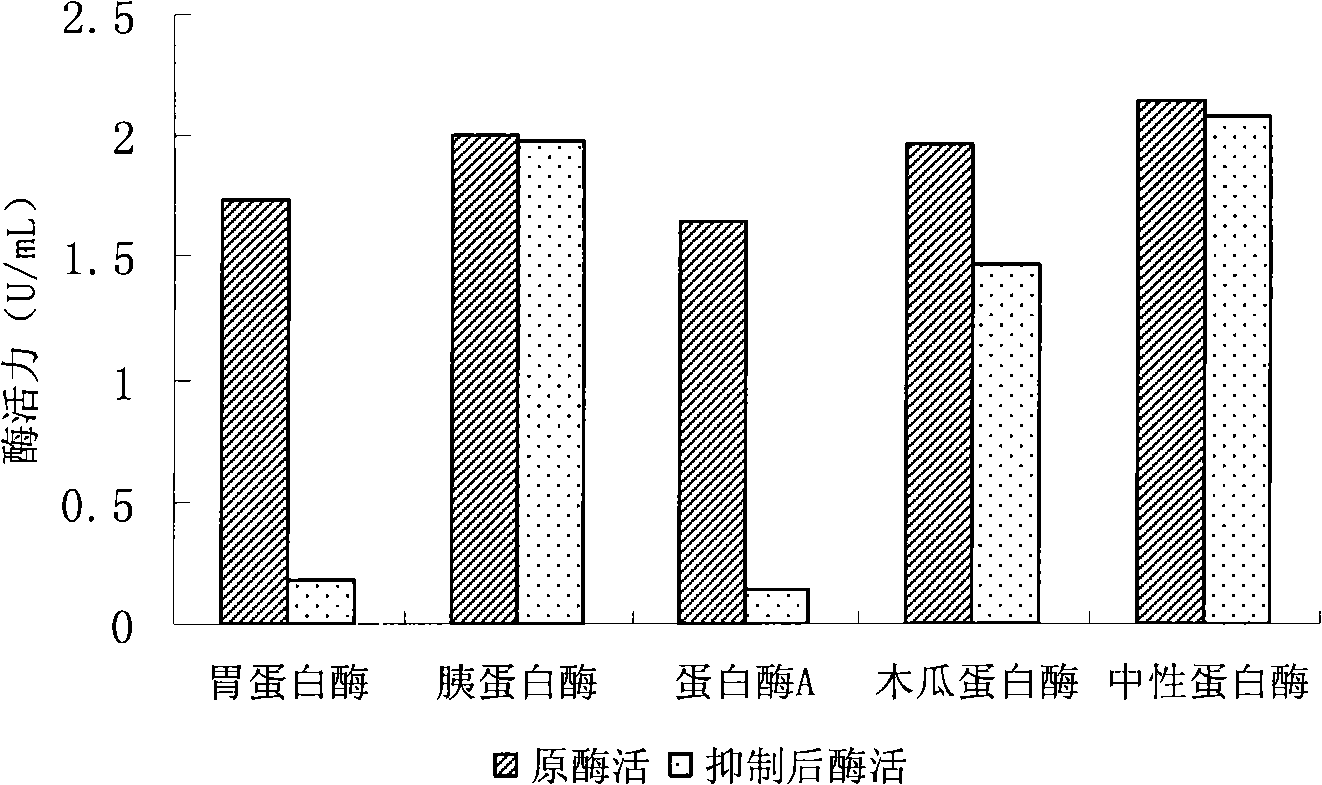

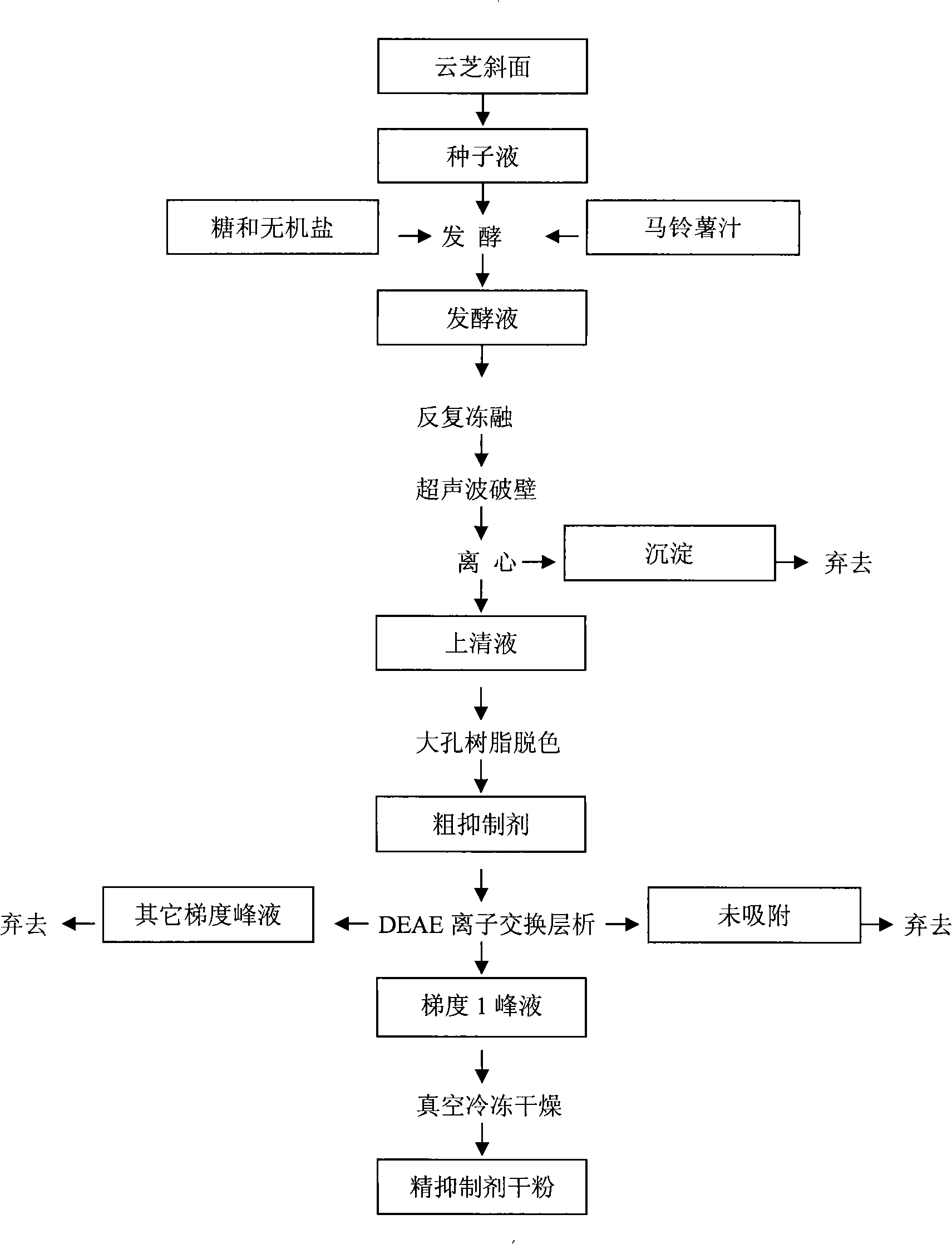

[0034] Put the Yunzhi slant into the seed medium, after cultivation, fill the flask with a liquid volume of 75mL / 250mL, and then put it into the fermentation medium according to the inoculation volume of 10%. The composition of the seeds and the fermentation medium is as described in the instructions. The initial pH was 6.0, cultured at 26°C and 170r / min for 5 days. Put the fermentation broth in a -20°C refrigerator to freeze, take it out and thaw it in a water bath at 30°C, and repeat this process 3 times; ultrasonically break the cells according to the ultrasonic time of 10min, power of 280W, temperature of 20°C, and processing capacity of 40mL, and centrifuge at 12000r / min for 15mim. The precipitate was discarded, and 65 mL of the supernatant collected after multiple batches of cell disruption and centrifugation was decolorized with macroporous resin D101 to obtain 60 mL of crude inhibitor, the concentration ratio of protein to sugar was about 0.77, and the IC for pepsin 50...

Embodiment 2

[0036] Insert the Yunzhi plate into the seed medium, after cultivation, fill the flask with a liquid volume of 75mL / 250mL, and then insert it into the fermentation medium according to the inoculation volume of 10%. The composition of the seeds and fermentation medium is as described in the instructions. The initial pH was 6.0, cultured at 26°C and 170r / min for 5 days. Place the fermentation broth in a -20°C refrigerator to freeze, take it out and thaw it in a water bath at 30°C, and repeat this process 3 times; ultrasonically break the cells according to the ultrasonic time of 10min, ultrasonic power of 280W, ultrasonic temperature of 20°C, and processing capacity of 40mL, and centrifuge at 12000r / min 15mim, discard the precipitate, and decolorize the 65mL supernatant collected after multiple batches of cell disruption and centrifugation with macroporous resin D101 to obtain a crude inhibitor. The concentration ratio of protein to sugar is about 0.93, and the IC for pepsin 50 ...

Embodiment 3

[0038] The Yunzhi plate is directly connected to the fermentation medium, and the composition of the fermentation medium is as described in the instructions. The initial pH was 6.0, cultured at 26°C and 170r / min for 5 days. Place the fermentation broth in a -20°C refrigerator to freeze, take it out and thaw it in a water bath at 30°C, and repeat this process 3 times; ultrasonically break the cells according to the ultrasonic time of 10min, ultrasonic power of 280W, ultrasonic temperature of 20°C, and processing capacity of 40mL, and centrifuge at 12000r / min 15mim, discard the precipitate, and decolorize the 65mL supernatant collected after multiple batches of cell disruption and centrifugation with macroporous resin D101 to obtain a crude inhibitor. The concentration ratio of protein to sugar is about 0.73, and the IC for pepsin 50 Value is about 1.99mg / mL, yield is about 83.4%; Get 15mL crude inhibitor and carry out DEAE52 ion-exchange chromatography, column specification is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com