One-bath scouring and bleaching method for cotton fabric combined with enzyme preparation

A technology of compounding enzymes and cotton fabrics, which is applied in the fields of enzyme/microbial biochemical treatment, bleaching products, textiles and papermaking, etc. It can solve the problems of shortening the treatment process, fabric damage, high pollution, etc., to improve the removal effect and reduce the pressure , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1: Traditional scouring and bleaching process (comparative example)

[0009] Fabric: Pure cotton poplin (15tex×15tex, 524 pieces / 10cm×283 pieces / 10cm)

[0010] Traditional scouring process: alkali scouring: NaOH 15g / L, penetrant JFC 5g / L, NaHSO 3 1g / L, Na 3 PO 3 1g / L, pH 13, temperature 95°C, bath ratio 1:20, treatment for 60 minutes.

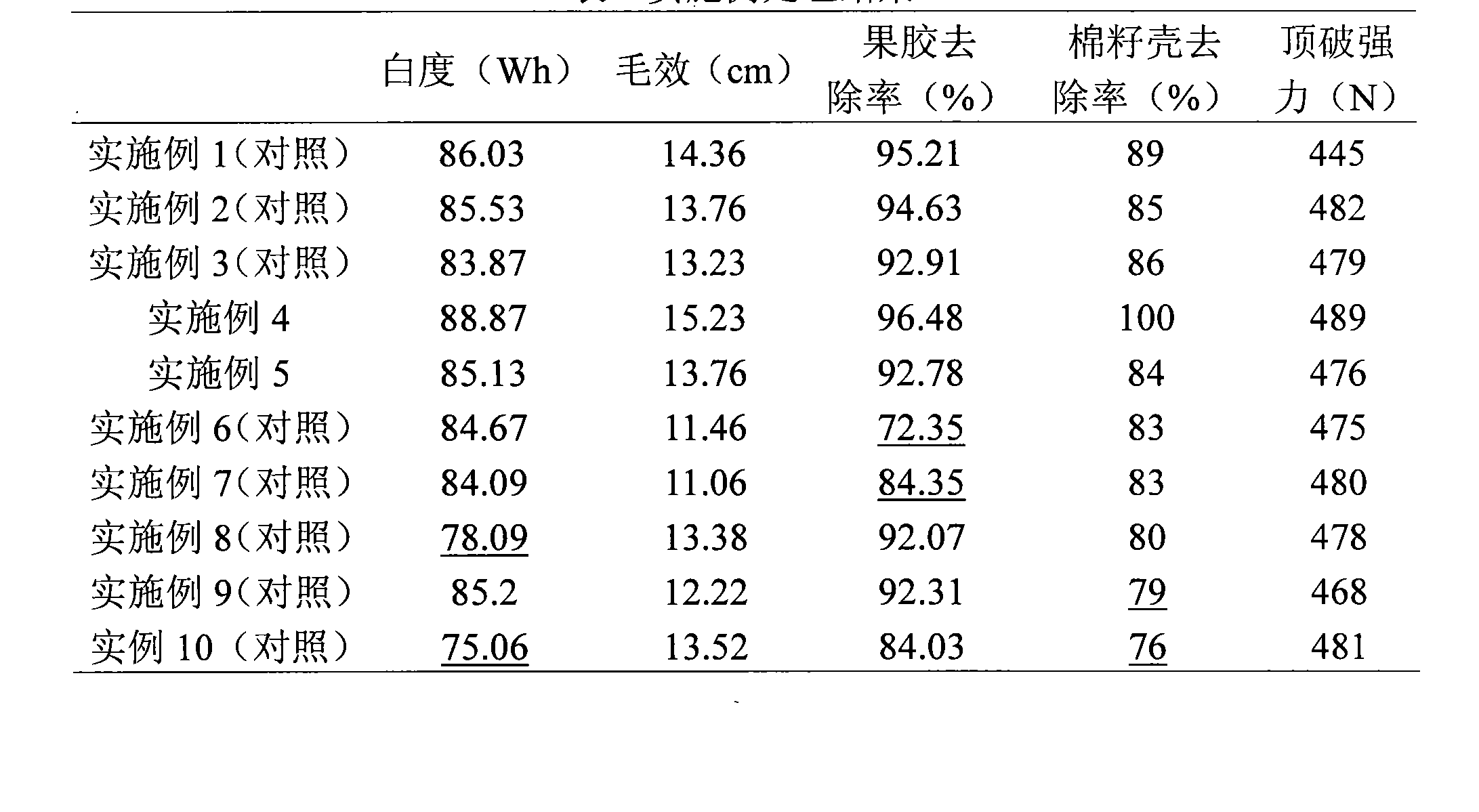

[0011] Traditional bleaching process: 30% H 2 O 2 5g / L, 1g / L oxygen bleaching stabilizer RB-3, pH 10.5, bath ratio 1:20, temperature 90℃, 60min. The results are shown in Table 1.

Embodiment 2

[0012] Example 2: Enzymatic scouring and traditional bleaching process (comparative example)

[0013] Fabric: Pure cotton poplin (15tex×15tex, 524 pieces / 10cm×283 pieces / 10cm)

[0014] Enzyme scouring: scouring enzyme preparation (cutinase, alkaline pectinase, alkaline xylanase, alkaline cellulase) 1.5g / L; penetrant JFC 5g / L, and 1g / L Triton X- 100; bath ratio 1:20, pH 10, temperature 60°C, 60min.

[0015] Traditional bleaching: 30% H 2 O 2 5g / L, 3g / L oxygen bleaching stabilizer RB-3, pH 11, bath ratio 1:20, temperature 90℃, 60min.

[0016] Enzymatic scouring of cotton fabric has the same treatment effect as alkali treatment, but the damage to the fabric is less. The results are shown in Table 1.

Embodiment 3

[0017] Example 3: Enzyme scouring cotton fabric, glucose oxidase generates hydrogen peroxide bleaching (different baths)

[0018] Fabric: Pure cotton poplin (15tex×15tex, 524 pieces / 10cm×283 pieces / 10cm)

[0019] Enzyme scouring: scouring enzyme preparation (cutinase, alkaline pectinase, alkaline xylanase, alkaline cellulase) 1.5g / L; penetrant JFC 5g / L, and 1g / L Triton X- 100; bath ratio 1:20, pH 10, temperature 60°C, 60min.

[0020] Bleaching process by adding sugar oxidase to generate hydrogen peroxide in the bleaching bath: composition of the bleaching bath: sugar oxidase 1.0g / L, glucose 3g / L, penetrant JFC 4g / L, 3g / L oxygen bleaching stabilizer RB-3, Bath ratio 1:20, pH 8, temperature 55°C, treatment for 60 minutes, then heat up to 90°C, then adjust pH 10, and act for 60 minutes for bleaching.

[0021] Sugar oxidase uses glucose as a substrate to generate hydrogen peroxide. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com