Large caliber ultra-long rubber plastic composite hose for oil extraction and producing method thereof

A composite hose and large-diameter technology, which is applied in the direction of hoses, pipes, and layered products, can solve the problems of inability to produce large-diameter and super-long rubber-plastic composite hoses, affecting the service life of lifting equipment, and high labor intensity. , to achieve the effect of easy operation, high tensile strength and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

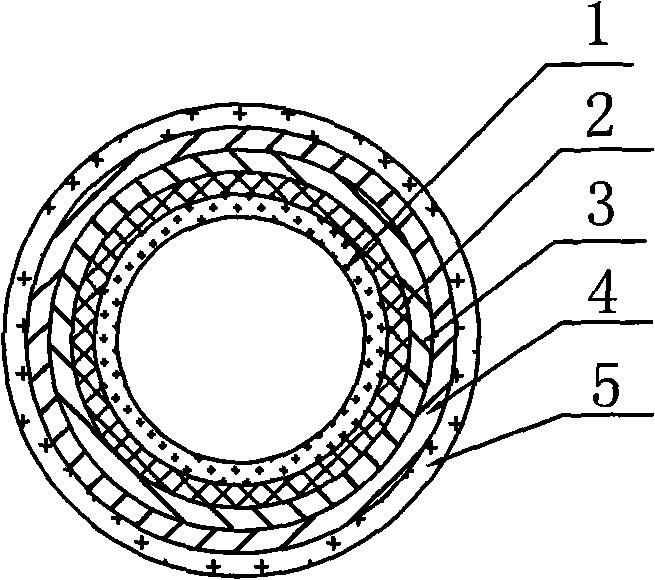

[0023] A heating layer, a first reinforcement layer, a second reinforcement layer and a rubber-plastic outer protective layer are sequentially arranged on the surface of the rubber-plastic alloy hose along the radial direction, and a rubber-plastic alloy rubber layer is arranged between each layer. The heating layer is a silicon rubber sheet with an electric heating element inside. This piece is an electric heating wire or an electric heating sheet, one end of which is electrically connected to form a single-phase circuit or a three-phase circuit and is connected to the power supply. The first reinforcement layer and the second reinforcement layer are copper-plated high-strength steel wire mesh layers with a mesh diameter of 0.35 mm and a mesh weaving angle of 40 degrees. The rubber-plastic composite hose has an inner diameter of 30mm and a length of 800m. The preparation method of this tube comprises the following steps:

[0024] 1. The step of preparing the rubber-plastic a...

example 2

[0032] The structure of the composite layer on the surface of the rubber-plastic composite hose is the same as that of Example 1, in which the heating layer is a silicon rubber sheet, and there is an electric heating sheet inside, and one end is electrically connected to form a three-phase circuit connected to the power supply. The first reinforcement layer and the second reinforcement layer It is a copper-plated high-strength steel wire mesh layer with a mesh diameter of 0.4mm and a mesh weaving angle of 60 degrees. The rubber-plastic composite hose has an inner diameter of 40mm and a length of 1500m. The preparation method of this tube comprises the following steps:

[0033] 1. The step of preparing the rubber-plastic alloy rubber material. This step 1 is based on the basic compounding amount and is measured according to the mass unit. Take:

[0034] 5075 rubber-plastic alloy 105 produced by Japan Duan Weng Rubber Co., Ltd., ZnO zinc oxide 5.2, SA stearic acid 1.2, PW paraf...

example 3

[0042] The structure of the composite layer on the surface of the rubber-plastic composite hose is the same as that of Example 1, in which the heating layer is a silicon rubber sheet, and there is a heating wire inside, and one end is electrically connected to form a three-phase circuit connected to the power supply. The first reinforcement layer and the second reinforcement layer It is a copper-plated high-strength steel wire mesh layer with a mesh diameter of 0.6mm and a mesh weaving angle of 70 degrees. The rubber-plastic composite hose has an inner diameter of 50mm and a length of 2000m. The preparation method of this tube comprises the following steps:

[0043] 1. To prepare the rubber-plastic alloy rubber material, according to the basic compounding quantity, and measure according to the mass unit, take:

[0044] 5075 rubber-plastic alloy 110 produced by Japan Duan Weng Rubber Co., Ltd., ZnO zinc oxide 5.5, SA stearic acid 1.5, PW paraffin wax 1.5, RD antioxidant 1.5, B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com