Methacrylate polymer solid-phase micro-extraction fibre and method of producing the same

A technology for methacrylic acid and fiber extraction, applied in solid solvent extraction, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of mechanical strength and lack of selectivity of quartz fibers that are not resistant to solvent cleaning, and achieve the goal of overcoming matrix interference, Effects of improving sensitivity and accuracy and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

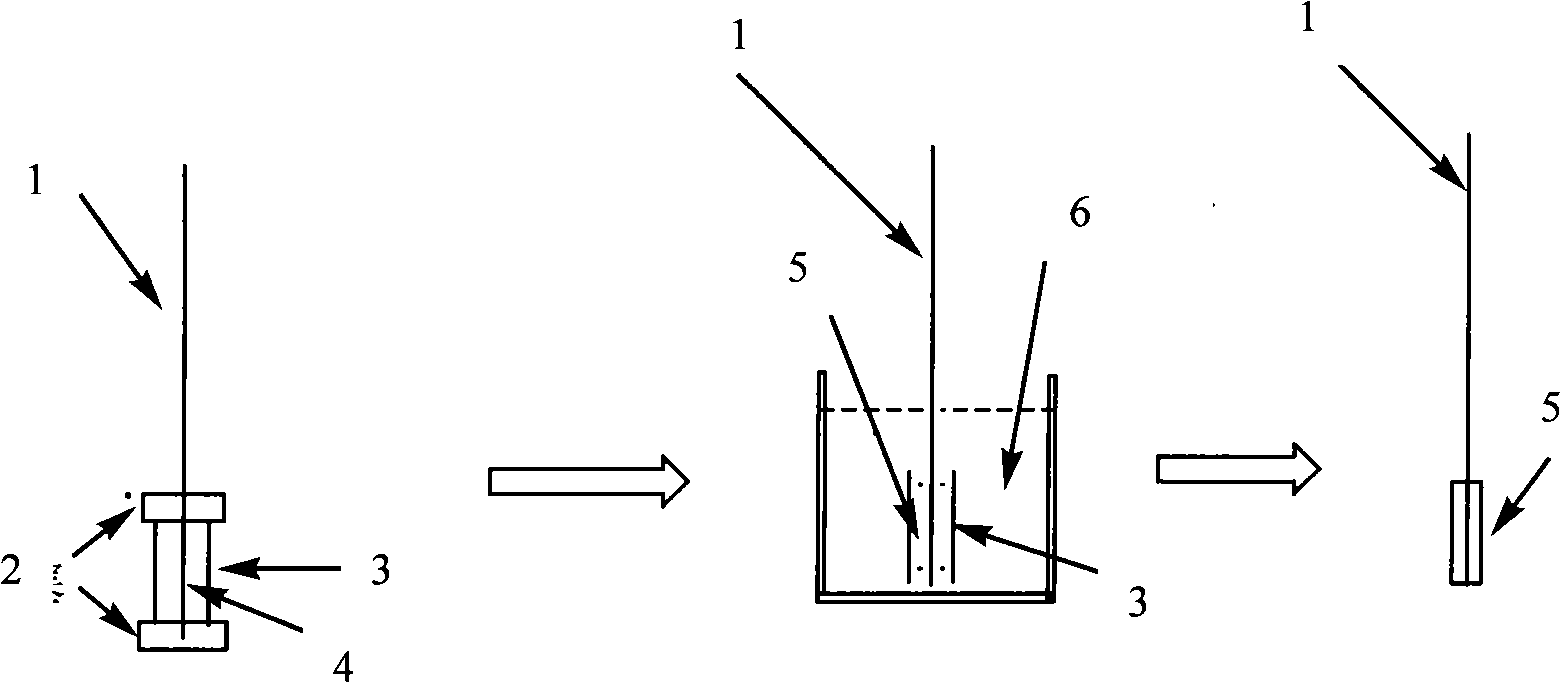

Method used

Image

Examples

Embodiment 1

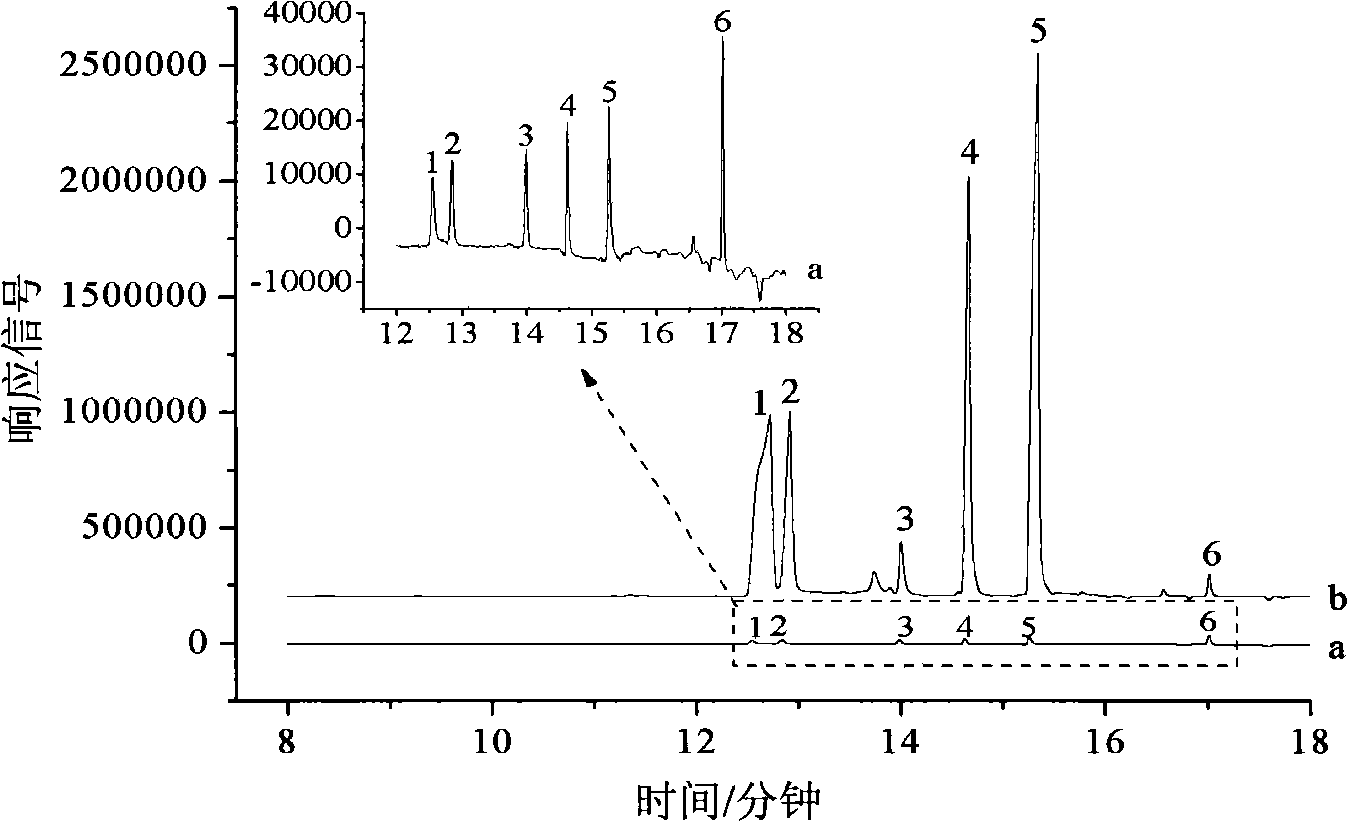

[0029] Example 1: The comparison between the extraction efficiency of the MAA / TRIM extraction fiber prepared by the present invention for the mixed standard of triazine and organophosphorus pesticide and the direct injection of the mixed standard is given below. Depend on figure 1 It can be seen that by Figure 4 It can be seen that the responses of triazines (peaks 1, 2, 4, 5) and organophosphorus pesticides (peaks 3, 6) on the detector are very close when the mixed solution is directly injected, and when the mixed solution is subjected to MAA / The response signal of triazine after extraction with TRIM extraction head is much higher than that of organophosphorus pesticides. This shows that the extraction fiber can have higher extraction efficiency and selectivity for triazine pesticides containing multiple amino groups through hydrogen bonding.

Embodiment 2

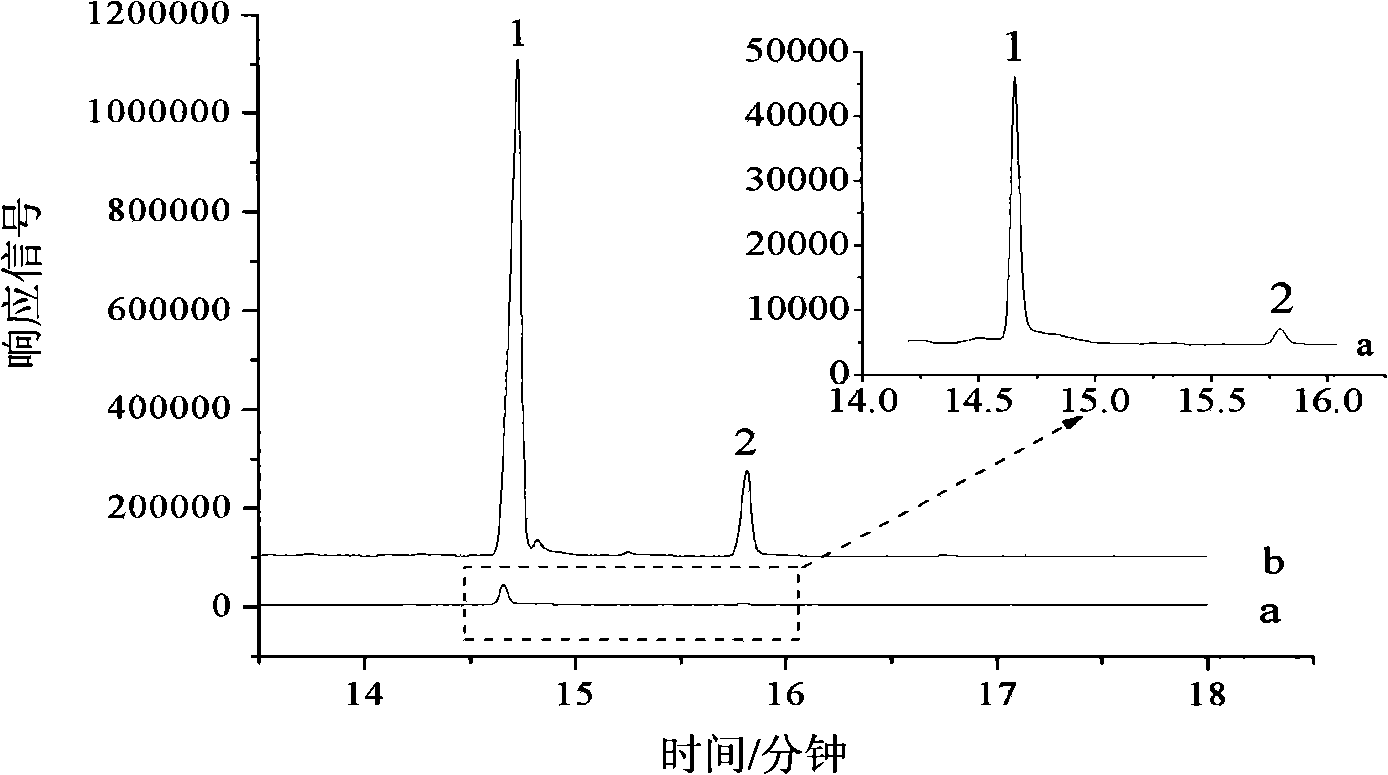

[0030] Example 2: The comparison between the extraction efficiency of heroin and acetylcodeine-n-hexane mixed standard prepared by the MAA / TRIM extraction fiber prepared by the present invention and the direct injection of the mixed standard is given below. Depend on figure 2 It can be seen that the response signal (peak area) on the detector after the heroin and acetylcodeine n-hexane mixed standard is extracted by the MAA / TRIM extraction head is greatly improved compared with the direct injection. This shows that the extraction fiber can have a higher extraction efficiency for opioids containing multiple hydroxyl groups and carbonyl groups through hydrogen bonding.

Embodiment 3

[0031] Example 3: The following is a comparison between the extraction efficiency of the MAA / TRIM extraction fiber prepared by the present invention for the phenoxycarboxylic acid pesticide n-hexane mixed standard and the direct injection of the mixed standard. Depend on Figure 4 It can be seen that the response signal (peak area) on the detector after the phenoxycarboxylic acid alkanes mixed standard is extracted by the MAA / TRIM extraction head is greatly improved compared with the direct injection. This shows that the extraction fiber can have a higher extraction efficiency for phenoxycarboxylic acid pesticides containing multiple carboxyl groups through hydrogen bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com