Method for air-water backwashing and surface cleaning natural filter bed filter material and a cleaning control system thereof

A technology of control system and water distribution system, which is applied in the field of water treatment to achieve the effect of less land occupation, low operating cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

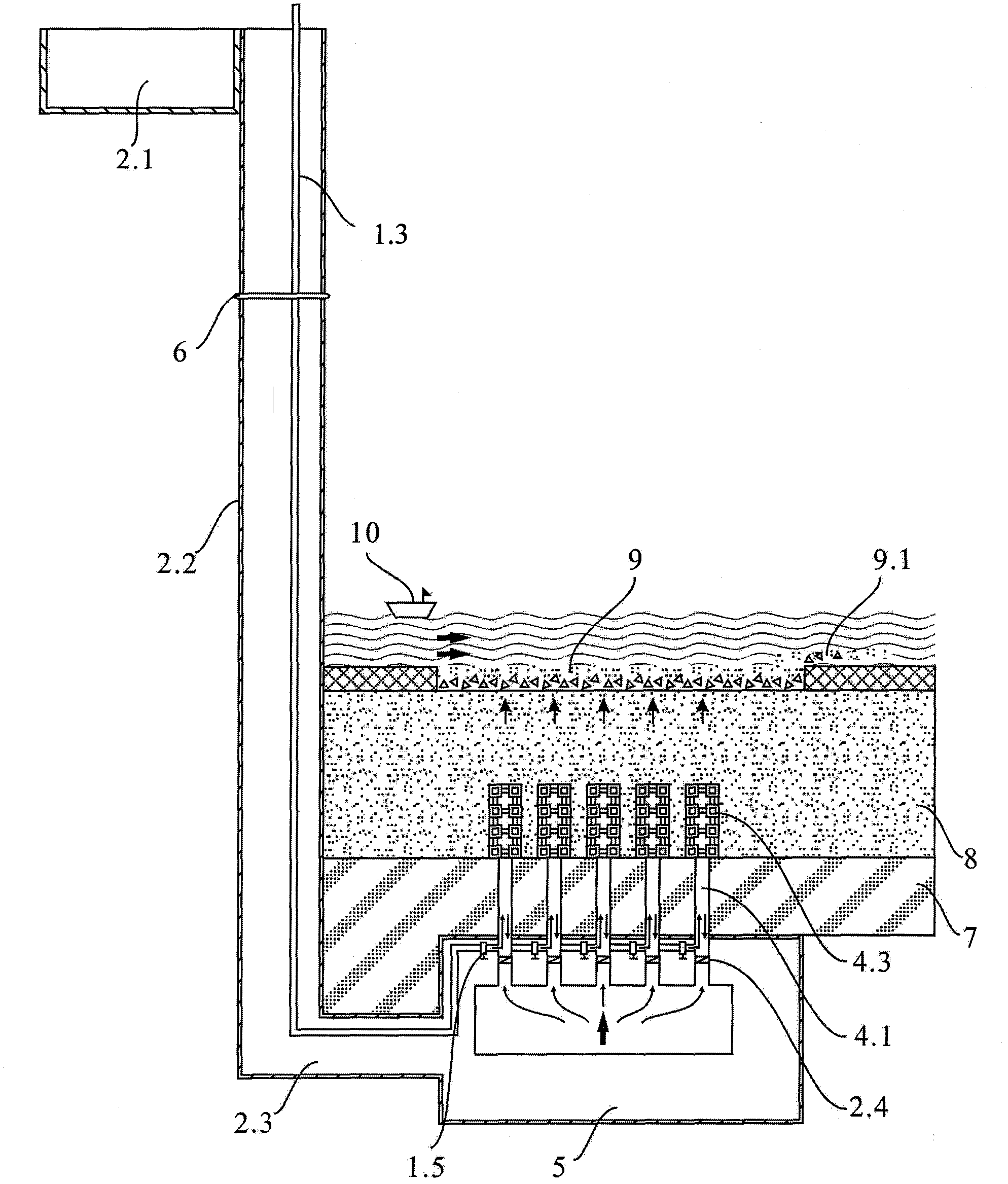

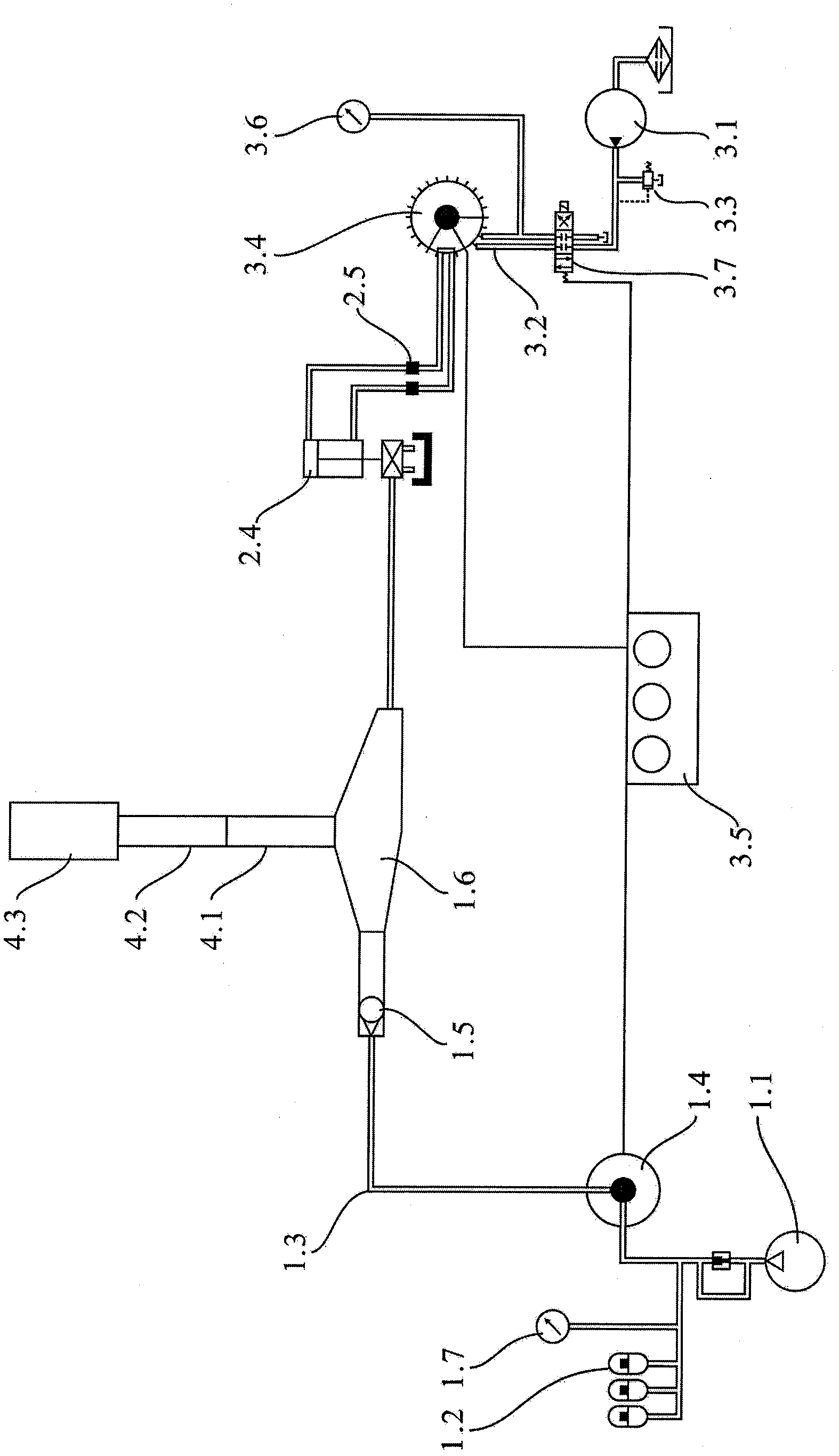

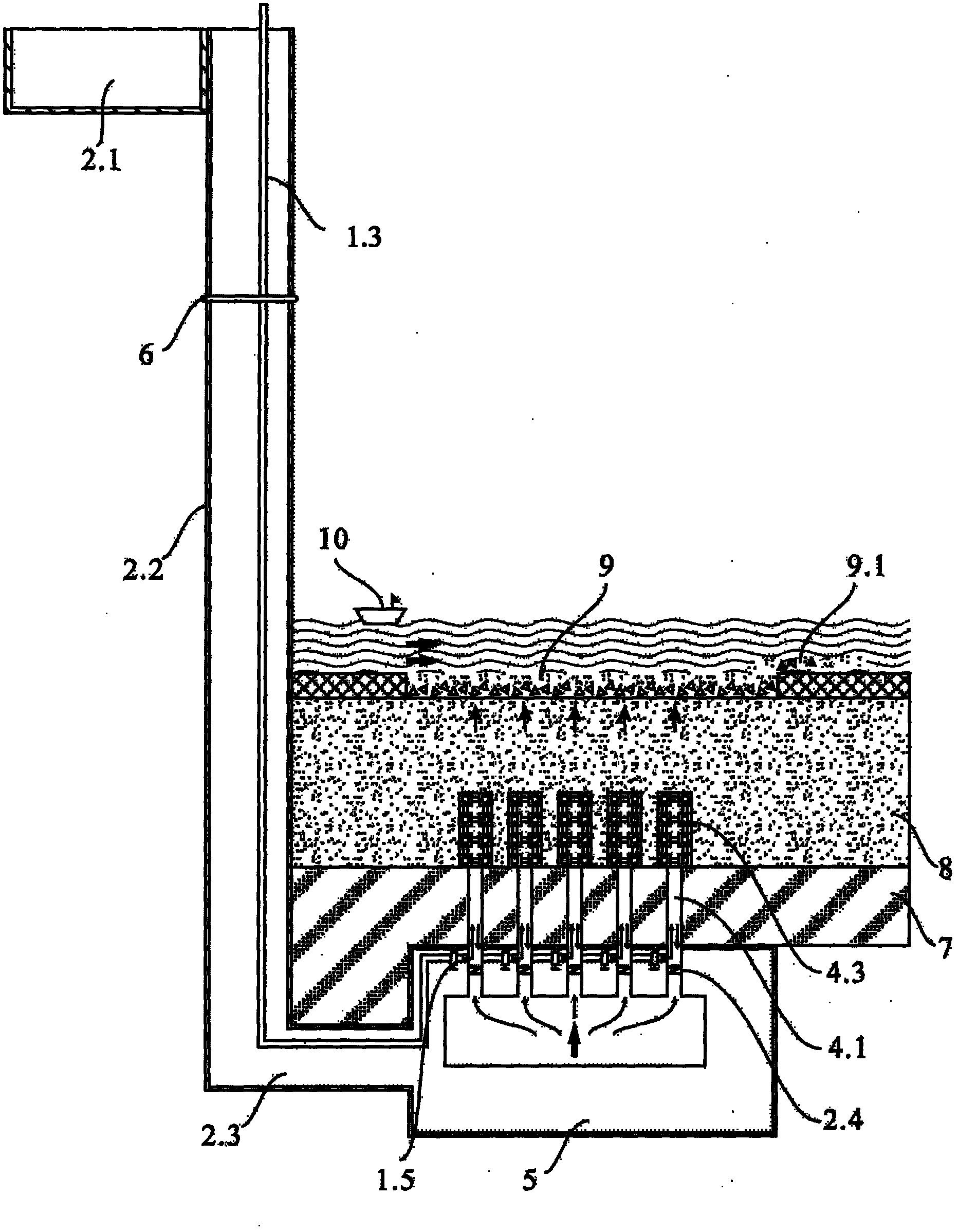

[0023] Such as figure 1 Shown, the natural filter bed filter material air-water backwashing surface sweeping method, reversely injects compressed air or water or gas-water mixture in the diversion pipe 4.1 of former natural filter bed percolation well, compressed air, water or The air-water mixture is sprayed out along the diversion pipe 4.1 and the percolation hole 4.2 and the filter 4.3 connected to the diversion pipe 4.1, using the gas lift generated by compressed air, the piping generated by hydraulic power or the gas-water mixture. Sorting breaks up the dense heterogeneous filter material 8 and silt layer 9 of the natural filter bed covered on the natural filter bed, and the silt and sediment 9.1 mixed in the filter material are under the action of gas lift, piping or sorting Moving upwards, the filter material heavier than the silt will fall back into the filter bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com