Biological filler shimmying-bed

A biological filler and microbial technology, which is applied in water/sewage multi-stage treatment, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. Treatment effect and other issues, to achieve the effect of easy to attach microorganisms, reduce the amount of sludge generation, and fast film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The planned wastewater volume and flow rate of this embodiment are shown in Table 1.

[0032] Table 1

[0033] project

m 3 / d

m 3 / h

m 3 / min

Daily average sewage volume

5.0

0.21

0.004

Time maximum sewage volume

-

0.63

0.011

[0034] The planned water quality of this embodiment is shown in Table 2.

[0035] Table 2

[0036] project

Influent water quality

target water quality

Removal rate (%)

BOD(mg / L)

200

10

95.0%

CODcr (mg / L)

400

50

87.5%

SS(mg / L)

100

10

90.0%

NH3-N(mg / L)

40

5

87.5%

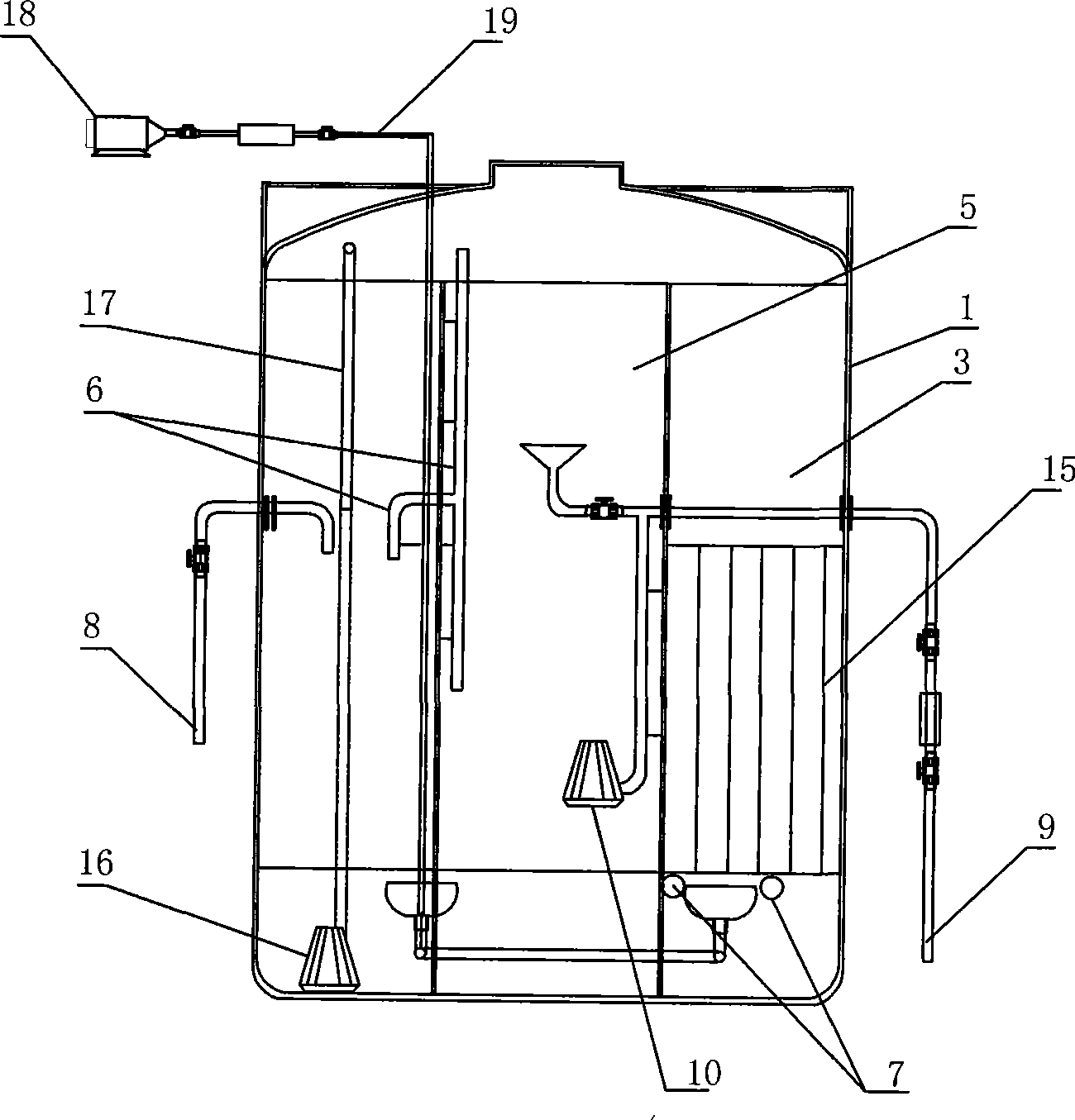

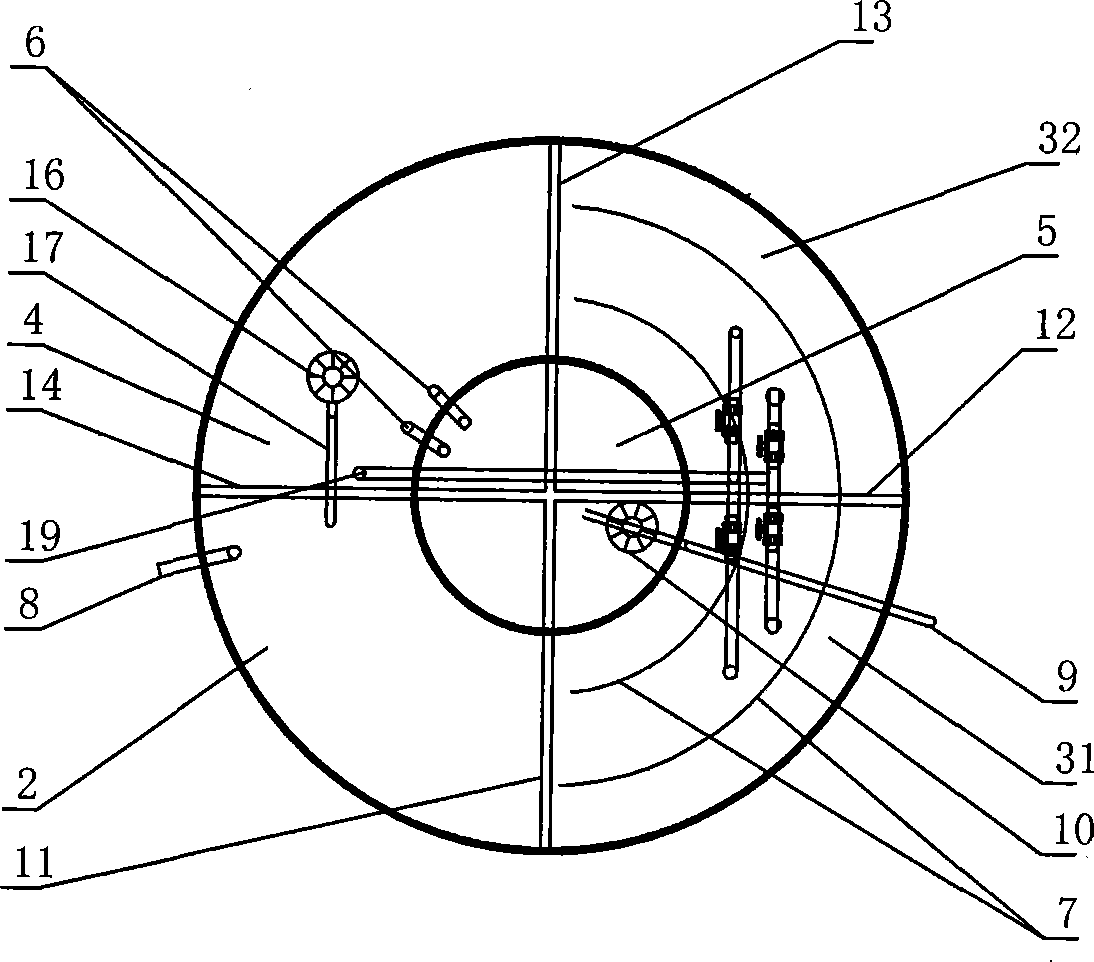

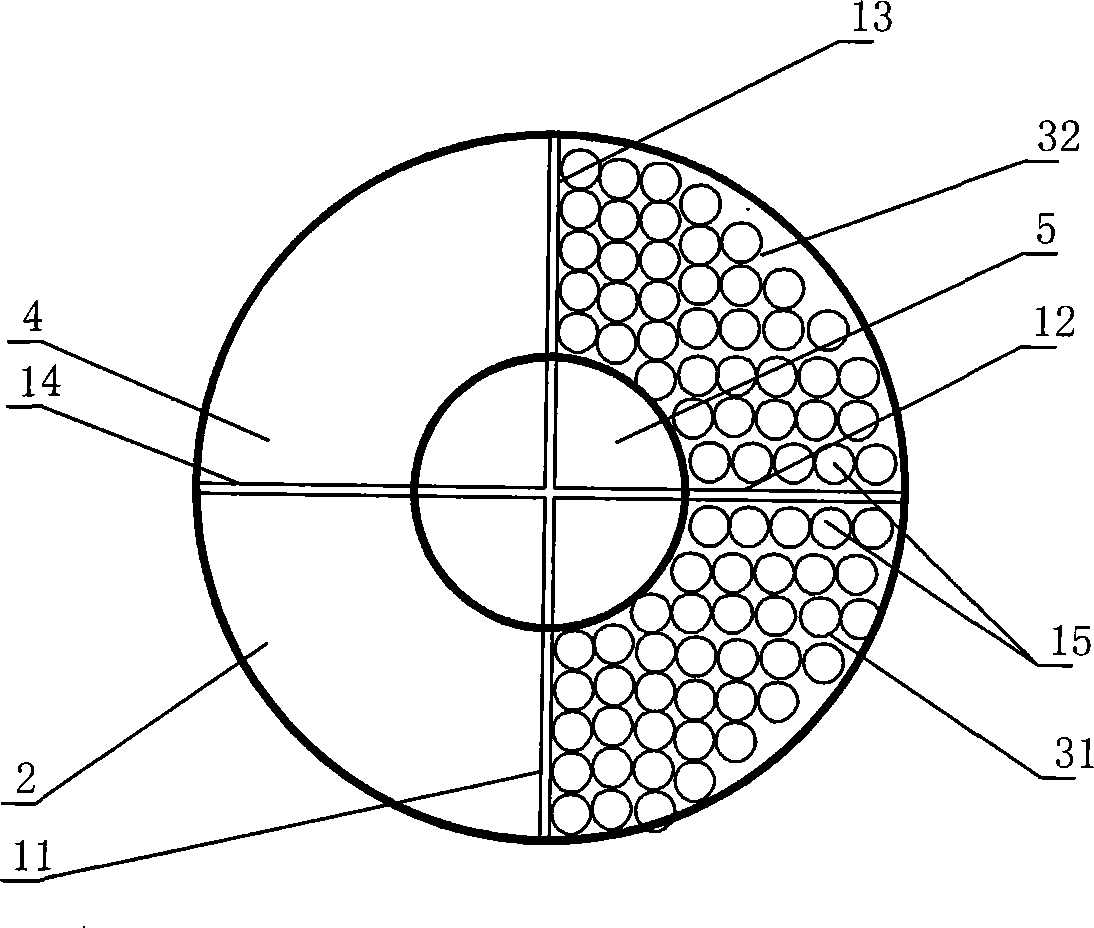

[0037] Such as figure 1 , 2 As shown, the shaking bed of biological filler in this embodiment is a carbon steel structure, the outer diameter of the shell 1 is 1800 mm, the effective depth is 2200 mm, and the radius of the clear water pool 5 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com