Aluminum nitride piezoelectric film and preparation thereof

An aluminum nitride piezoelectric and aluminum nitride technology, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as difficult realization, and achieve improved compactness, improved adhesion, The effect of avoiding structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

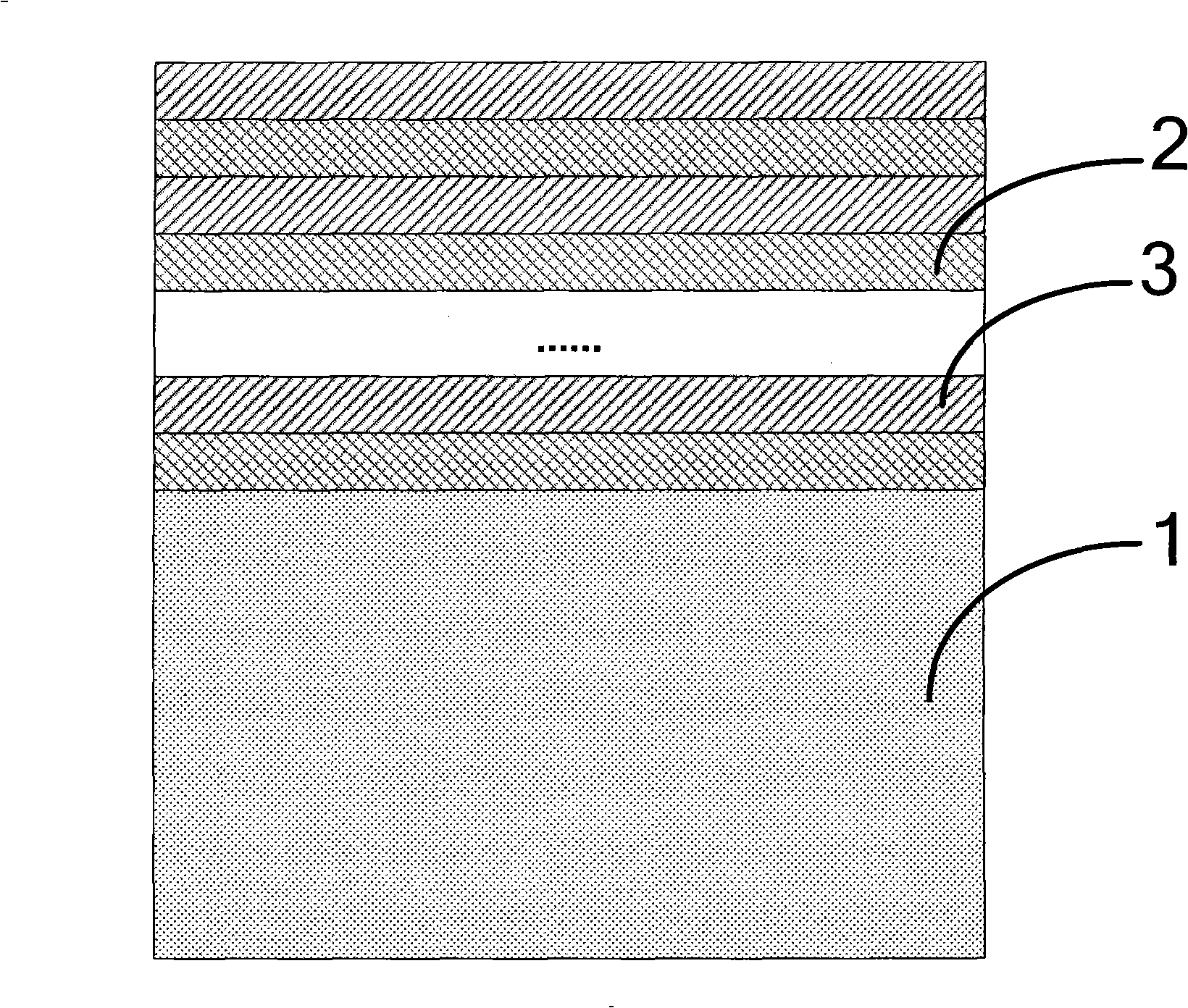

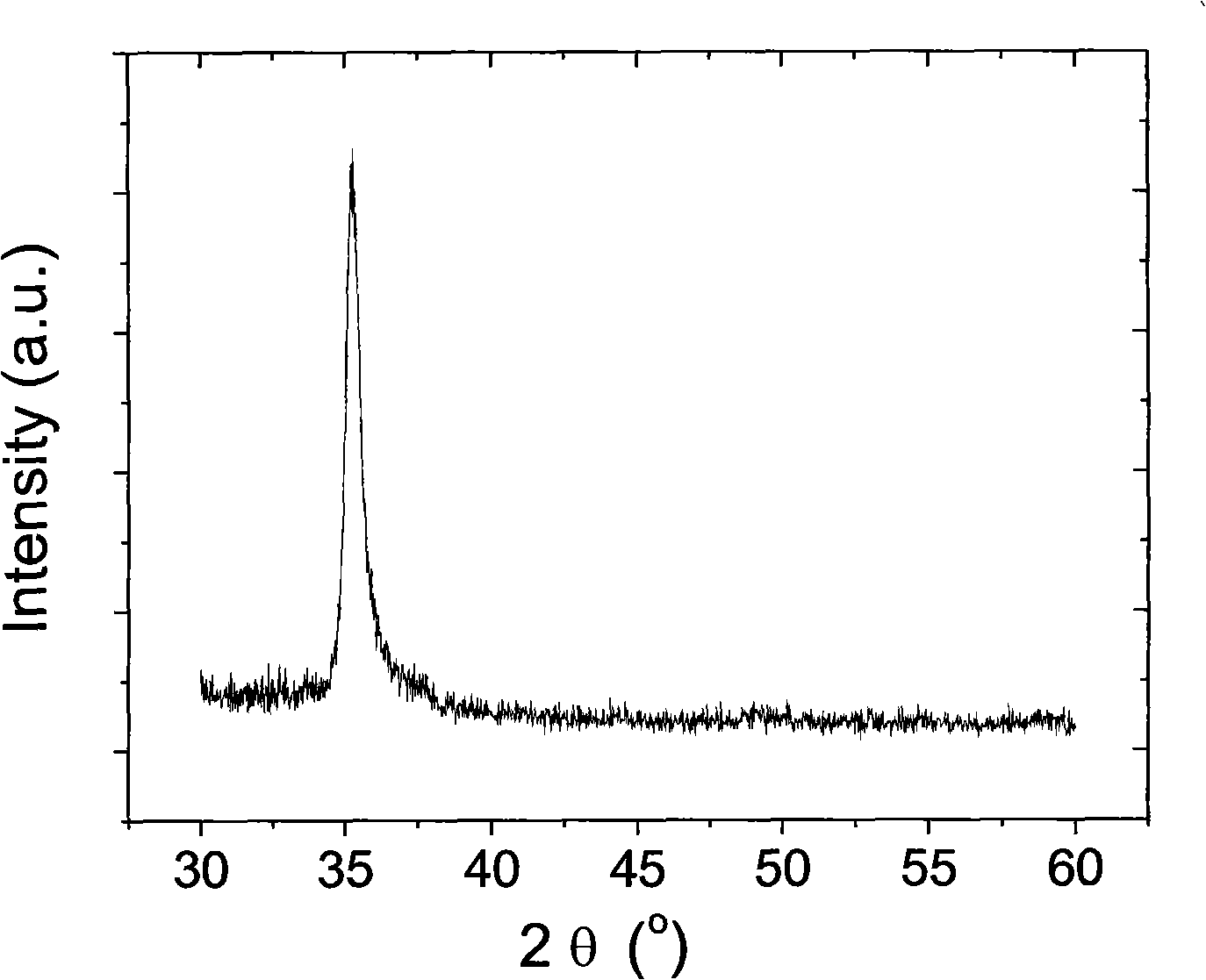

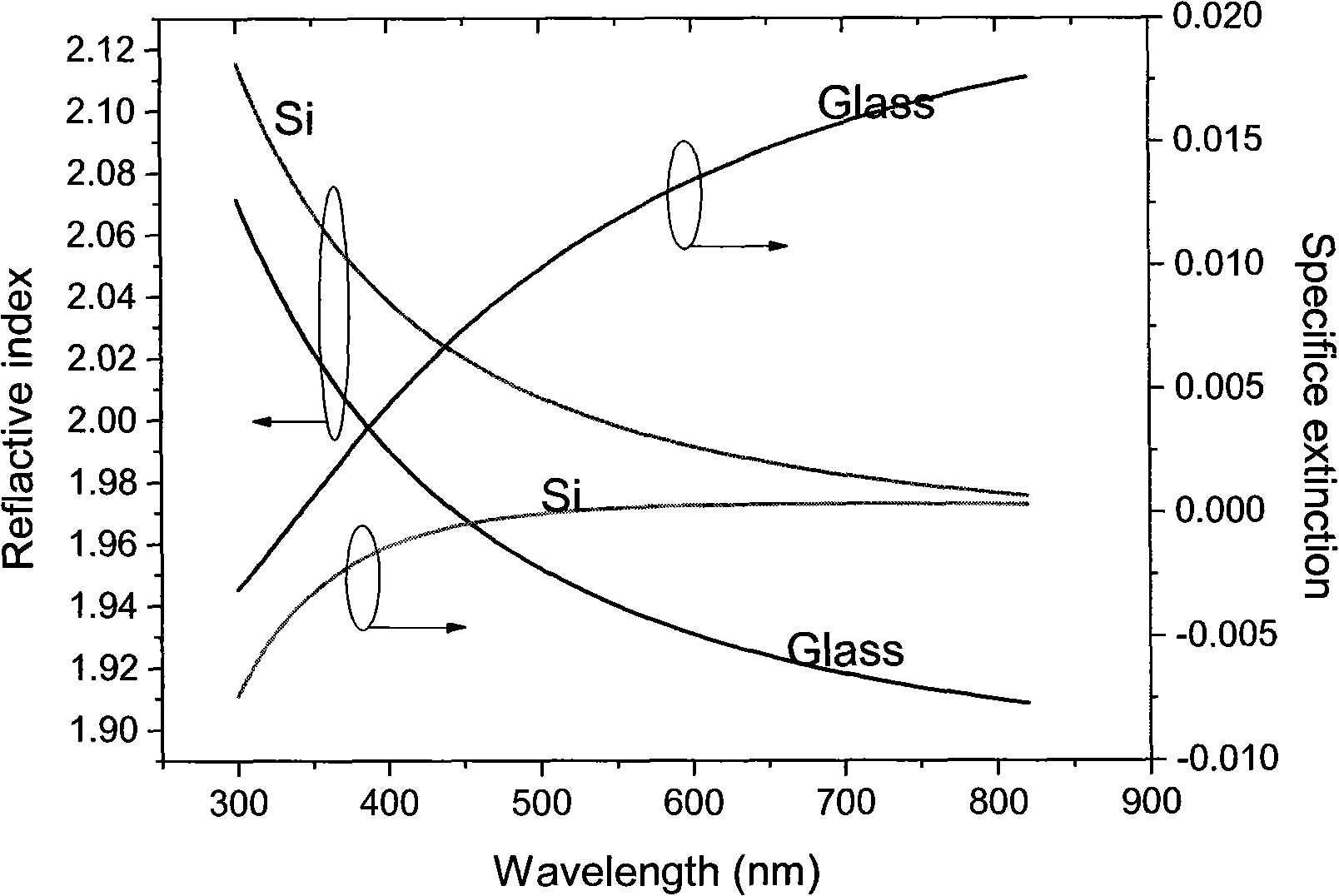

[0051] As a specific embodiment of the present invention, a radio frequency magnetron sputtering apparatus and an aluminum target are used, and a Si sheet is used as the substrate. Firstly, the substrate was ultrasonically cleaned in acetone, isopropanol and absolute ethanol for 15 minutes, then rinsed with deionized water for 10 minutes, dried with dry nitrogen, and placed on the substrate holder of the sputtering apparatus. Before coating, use a molecular pump to pump the air pressure in the vacuum chamber to 7×10 -4 Pa, while heating the substrate temperature to 400°C. Introduce the working gas Ar gas into the vacuum chamber, so that the working pressure in the vacuum chamber is 0.4Pa, adjust the radio frequency sputtering power to 400W, use the Ar gas glow to bombard the surface of the aluminum target for 15min, and remove the impurities or oxide layer attached to the surface of the aluminum target. Introduce reaction gas N 2 Gas, adjust the flow rate of nitrogen and arg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com