Growing method of carbon-doped sapphire crystal by EFG method

A technology of sapphire crystal and guided mode method, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of complicated process, difficult to ensure uniform distribution of carbon, difficult to obtain uniform quality, etc. Thermoluminescence and photoluminescence properties, the effect of good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Flake α-Al 2 o 3 : Preparation of C crystals

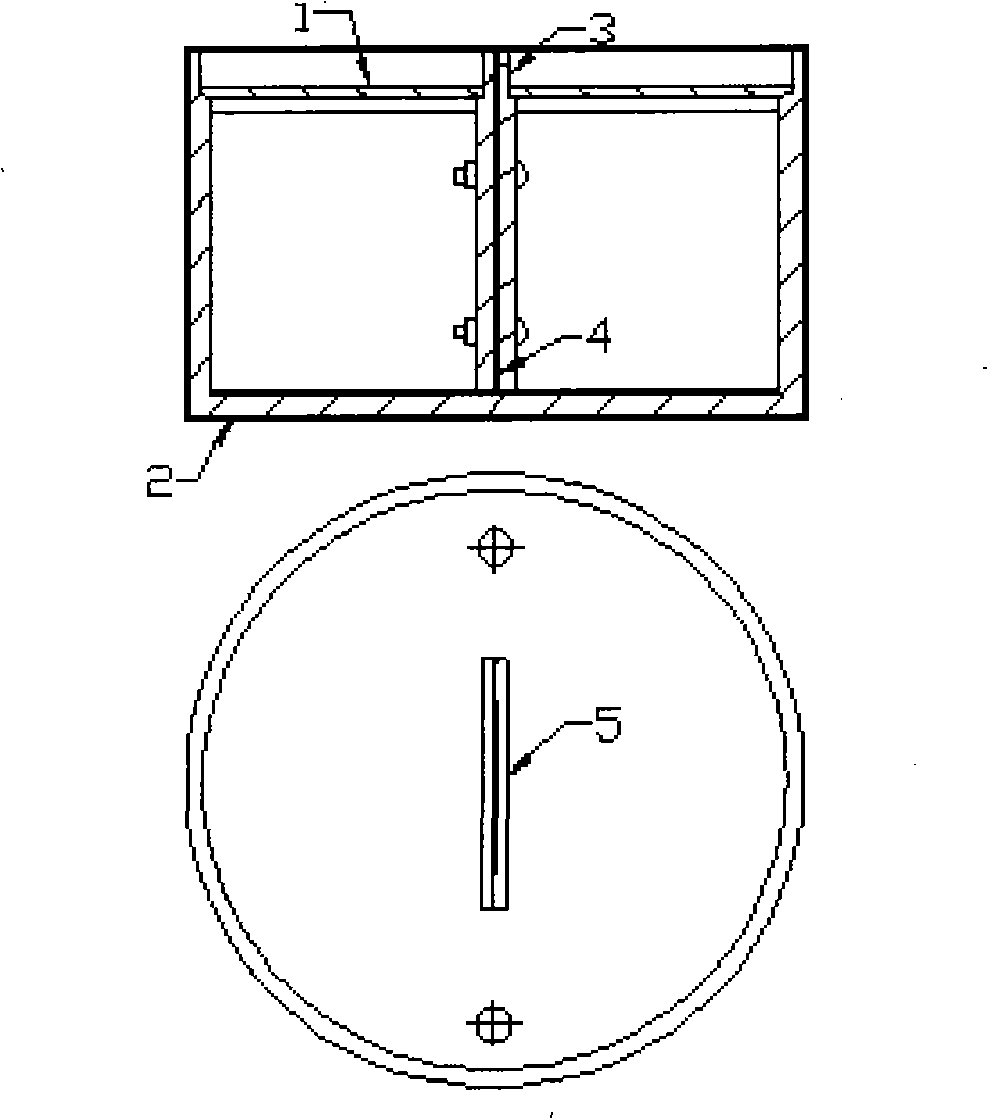

[0024] Weigh 500 grams of 99.999% α-Al 2 o 3 , cold-pressed into a cylindrical block at 200MPa, and then sintered at 1500°C for 24 hours in a silicon-molybdenum rod high-temperature furnace. figure 1 It is the present invention to grow flake α-Al 2 o 3 : Schematic diagram of molybdenum crucible and mold used for C crystal. Open the top cover 1 and the sintered α-Al 2 o 3 The block is put into the crucible 2 and put into the pulling furnace. Vacuum the pulling furnace to 5×10 -3 Pa, graphite resistance heating continues to heat up to 2080 ° C, constant temperature for 0.5 hours; control the temperature at the top of the guide mode 3 to make it slightly higher than the melting point of the crystal, and then Direction seed crystal is put down, and it is contacted with the molten liquid surface of guide mold 3 tops, pay attention to the melting of observation seed crystal end. The end of the seed crystal ...

Embodiment 2

[0026] Example 2: Growth of α-Al in different shapes 2 o 3 :C crystal

[0027] in α-Al 2 o 3 :C In the application process of crystals, there may be specific requirements for crystal shapes, such as rods, tubes, fibers, etc. The most prominent feature of the guided mode method is that it can grow crystals with special shapes, and the shape of the crystals is controlled by designing the cross-section of the top of different guided mode molds. Growth of tubular and rod-shaped α-Al 2 o 3 : The schematic diagram of the crucible with the guide mode mold designed by C crystal is as Figure 4 with Figure 5 As shown, the crystal growth process is the same as in Example 1. Anneal the grown crystals under high temperature hydrogen conditions to obtain α-Al with excellent thermoluminescent and optical luminescent properties 2 o 3 :C crystal.

Embodiment 3

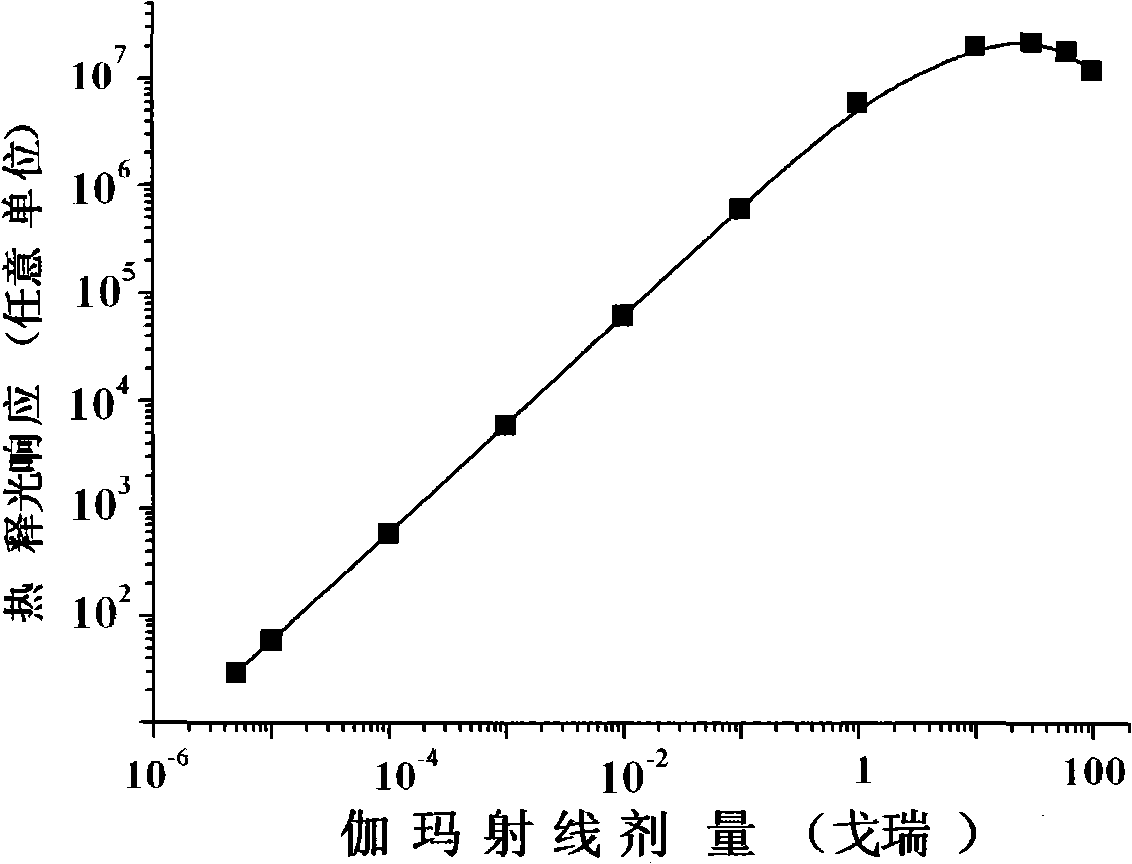

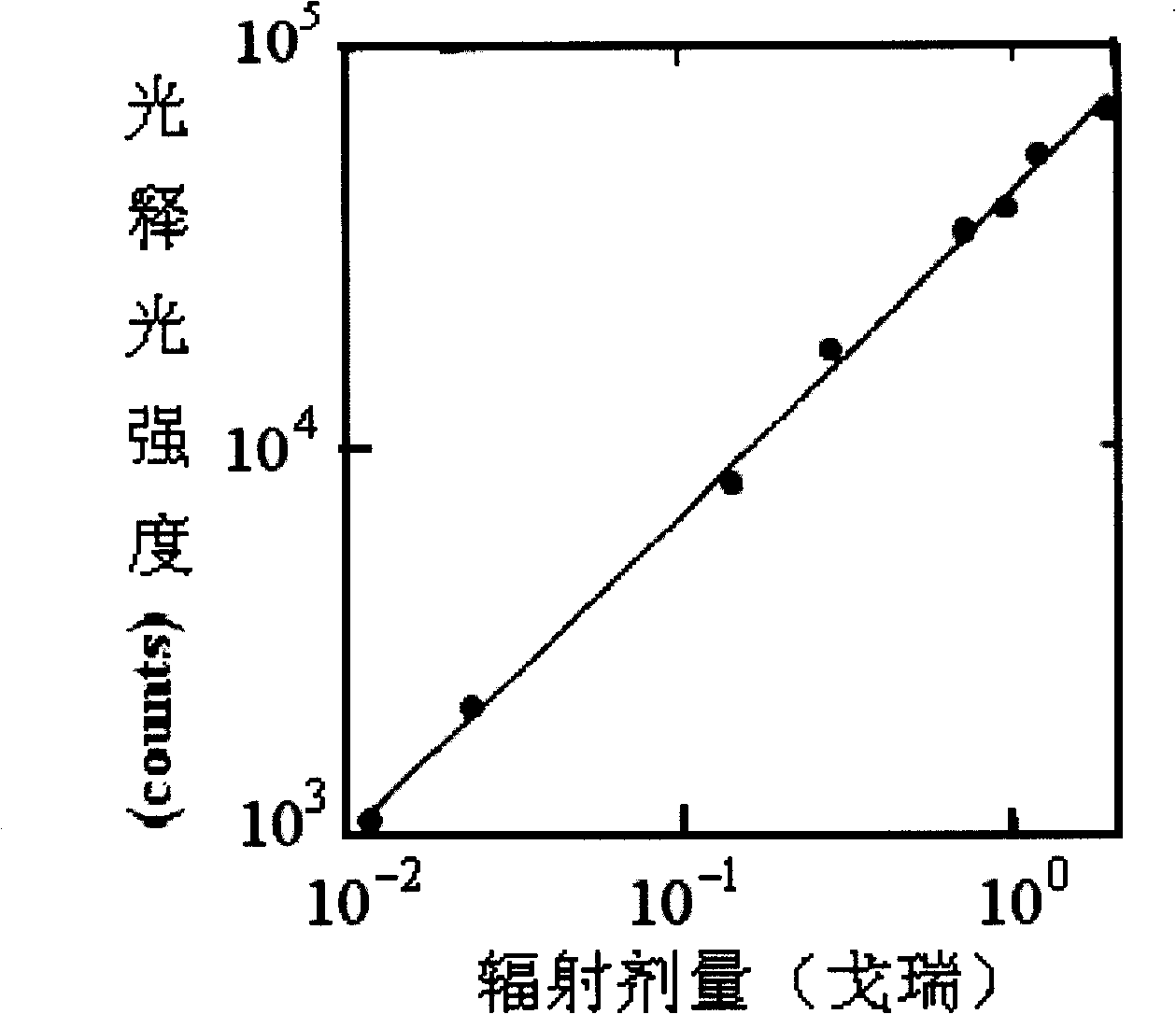

[0028] Example 3: α-Al obtained at different hydrogen annealing temperatures 2 o 3 :C crystal

[0029] α-Al grown by guided mode method 2 o 3 :C crystals were kept at 1000°C, 1250°C, and 1500°C for 80 hours under hydrogen atmosphere respectively. It was found that the crystals after hydrogen annealing at different temperatures have thermoluminescence and photoluminescence characteristics, but the intensity of thermoluminescence and photoluminescence changes under the same irradiation dose, which is mainly related to the F color center existing in the crystal . With the increase of hydrogen annealing temperature, the oxygen vacancies in the crystal gradually increase, resulting in the increase of F color center defects in the crystal, so α-Al 2 o 3 : The luminescence peak of C crystal at 190°C is enhanced, and the luminescence peak intensities at 190°C of crystals annealed at 1000°C, 1250°C, and 1500°C measured by X-ray irradiation for 10 seconds are 2300cps, 6700cps, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com