Hydrogen preparing process by reacting surface-modified pure alminuim powder with water

A technology of surface modification and process method, applied in the direction of hydrogen production, etc., can solve the problems of strong alkali pollution, slow reaction of metal Fe, etc., and achieve the effect of cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

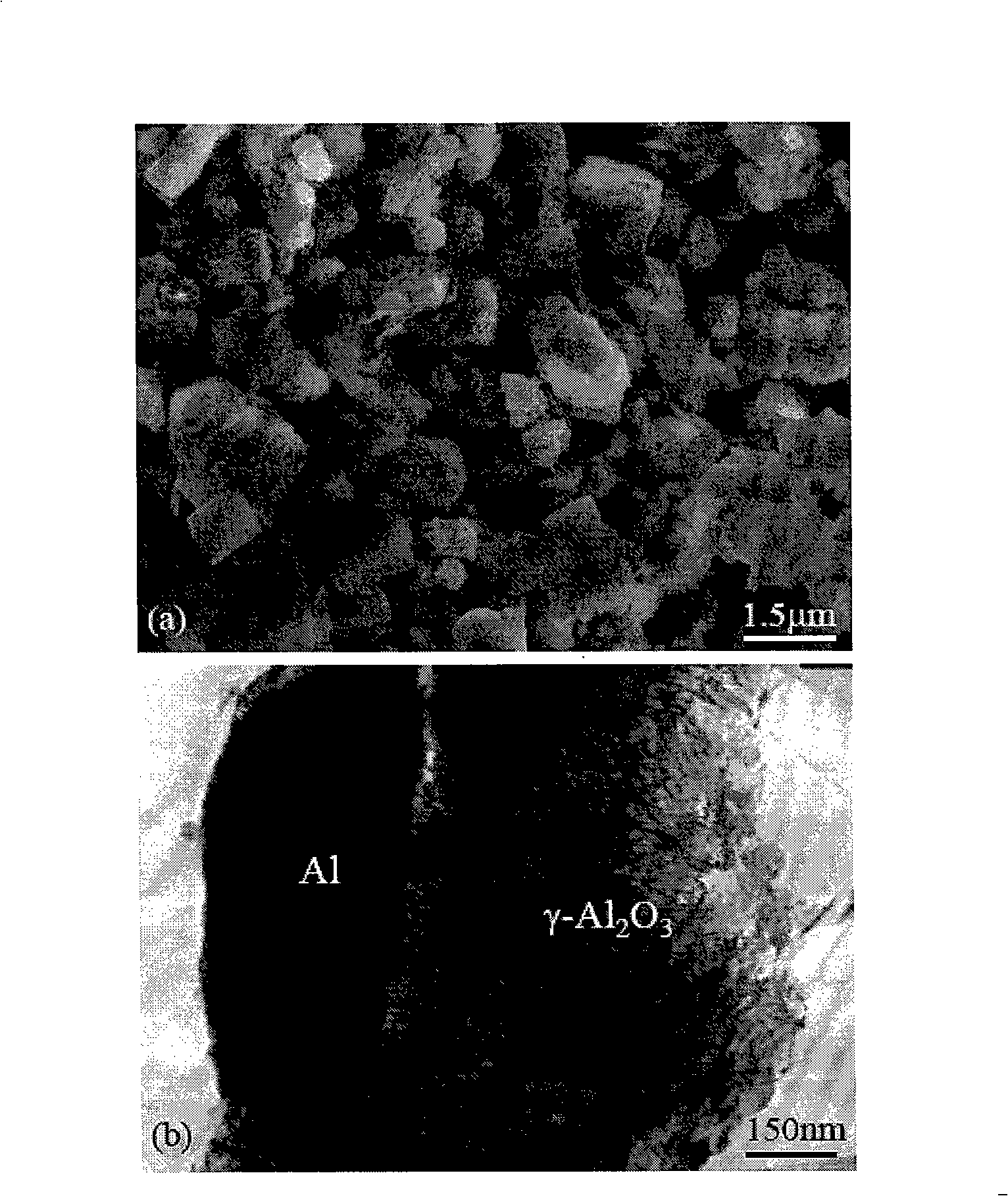

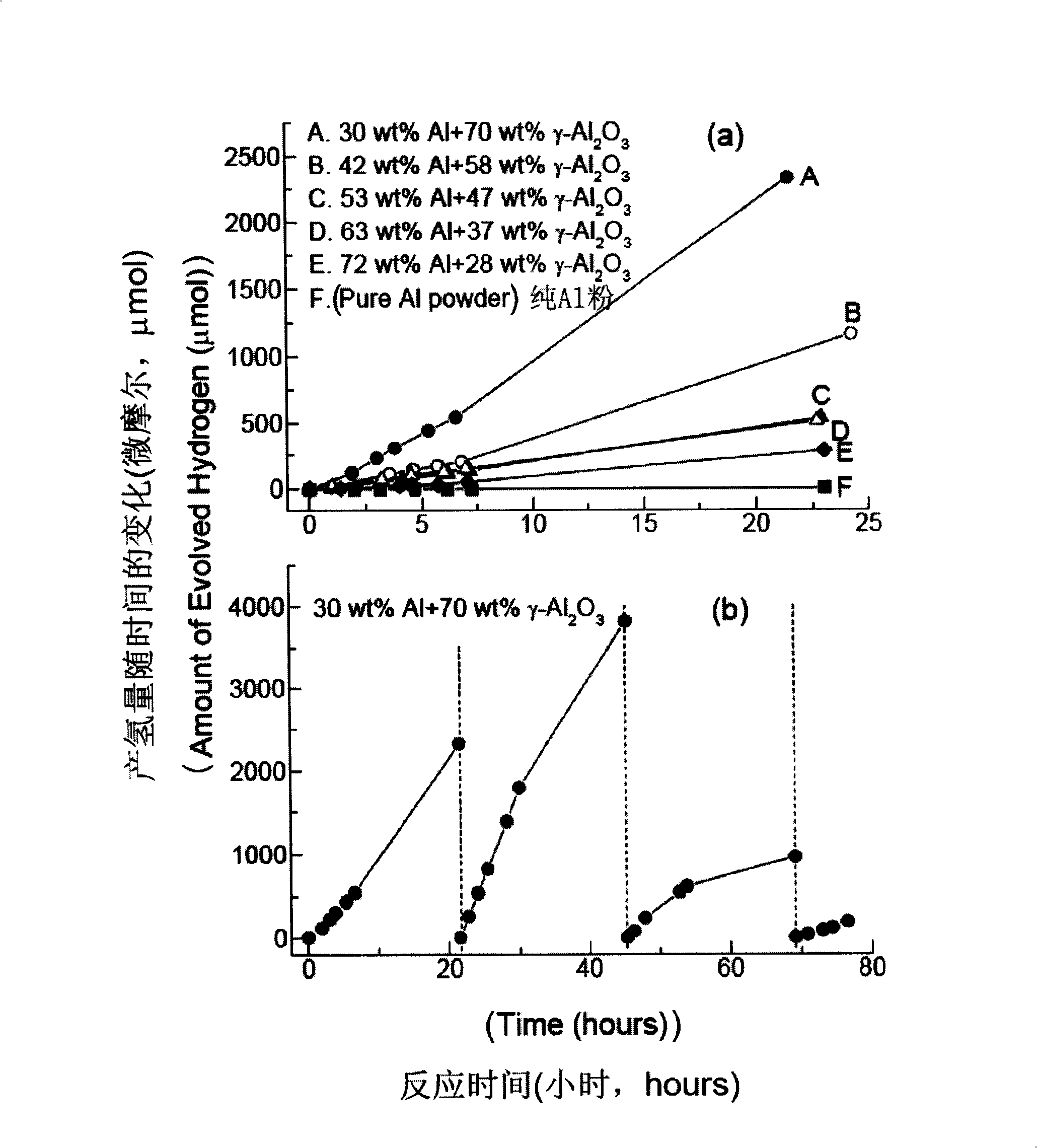

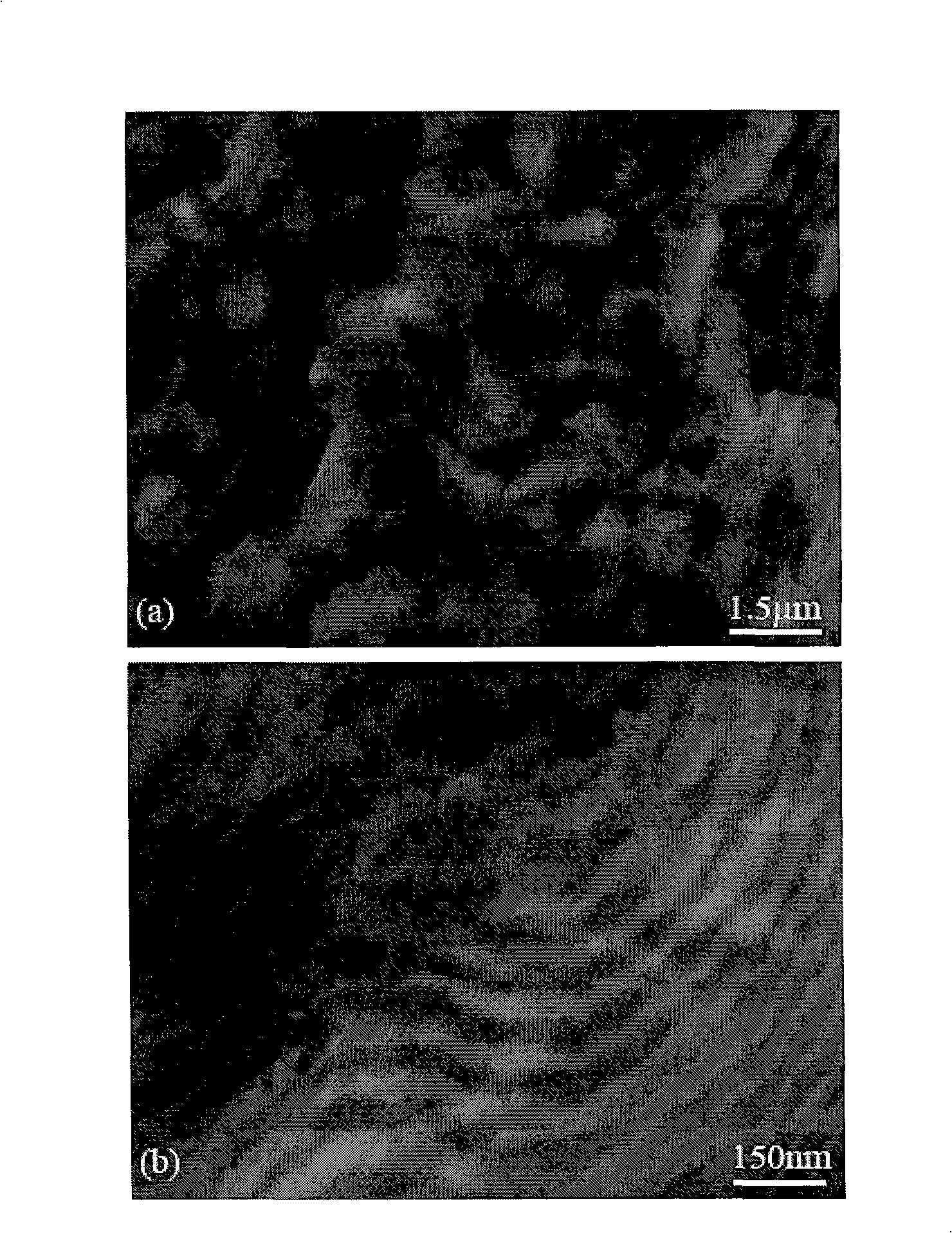

[0035] Example 1: A certain amount of Al powder with a particle size of 3 μm and a certain amount of Al(OH) with a particle size of 3 μm 3 After the powder is evenly mixed, an appropriate amount of ethanol is added, the mixed powder is ball-milled for 48 hours, and then dried. The dried mixed powder is pressed into a block with a unidirectional pressure of 120MPa; the block is heated to 600°C with a heating rate of 1°C / min under vacuum, and sintered and calcined for 1 hour, and then cooled to room temperature; the calcined block After the body is crushed and sieved, the surface is treated with γ-Al 2 o 3 Modified Al powder.

[0036] React the above-mentioned modified and activated aluminum powder with pure water under normal pressure and normal temperature of 18°C to generate hydrogen gas. The reaction equation is:

[0037]

[0038]The reaction can produce up to 4.8 mass% hydrogen (the ratio of the weight of hydrogen produced to the total weight of aluminum and water)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com