Process for preparing reactive dye and active deep red C-D by micro- reactor

A microreactor and active technology, which is applied in the direction of reactive dyes, chemical instruments and methods, azo dyes, etc., can solve the problems of large geometric size, and achieve the effects of preventing side reactions, making products environmentally friendly, and avoiding side reactions

Inactive Publication Date: 2008-10-15

赵卫国

View PDF0 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the large geometric size of conventional reactors, the reaction materials can be thousands of liters or tens of thousands of liters, and it is almost impossible to achieve instant mixing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

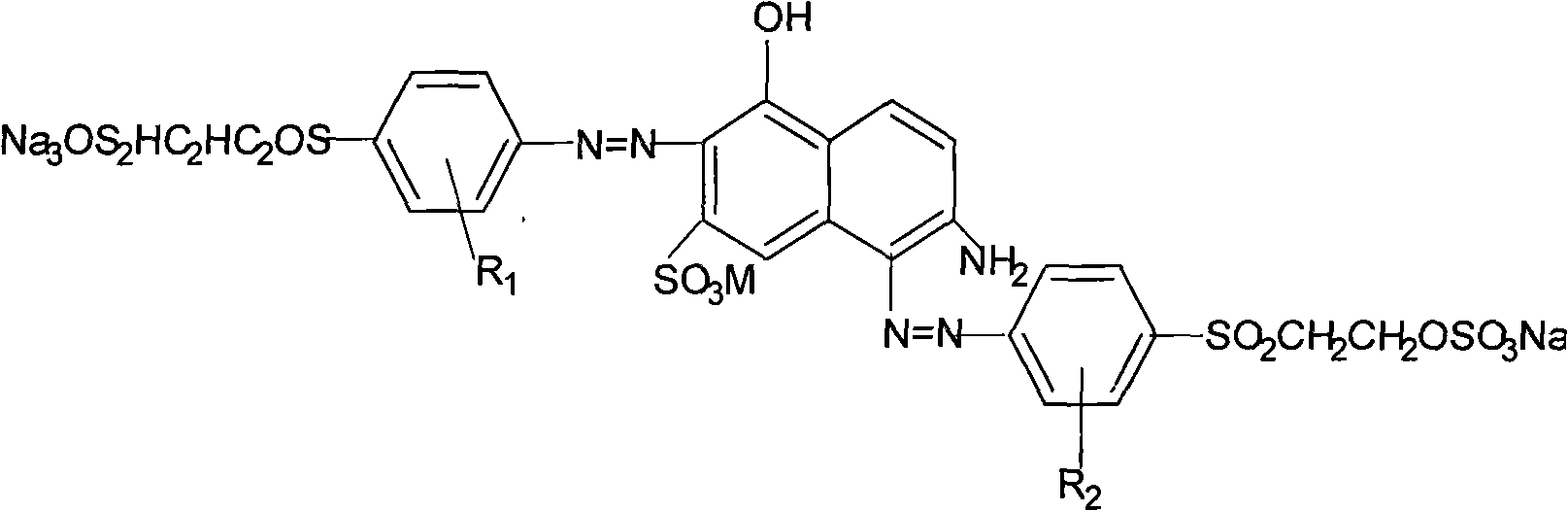

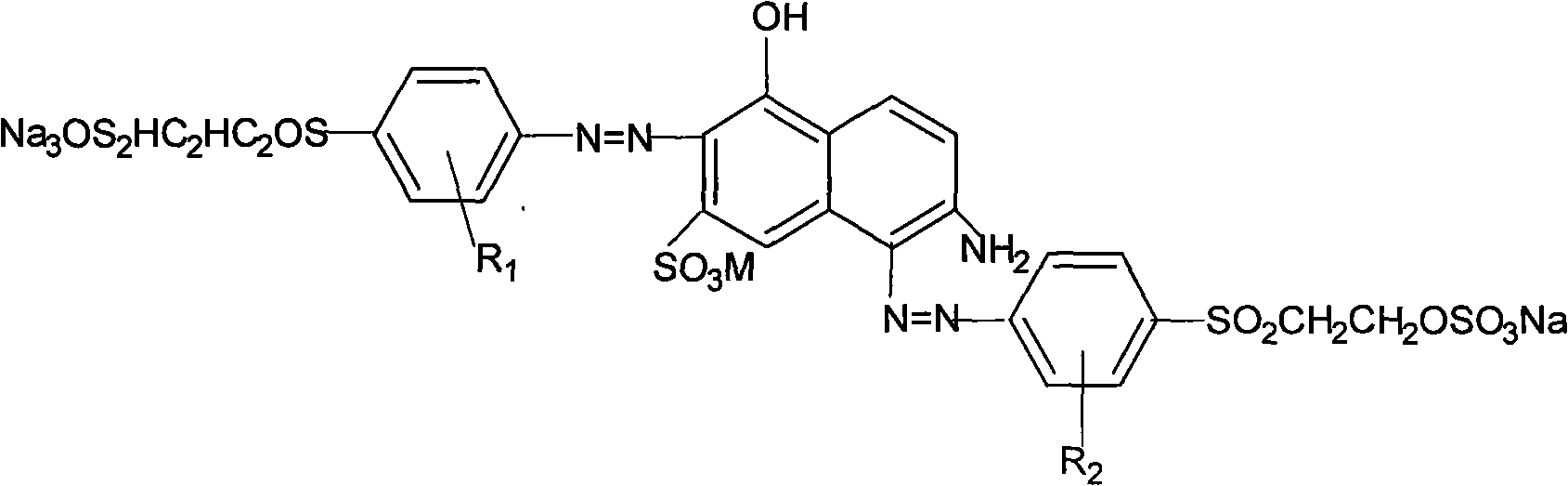

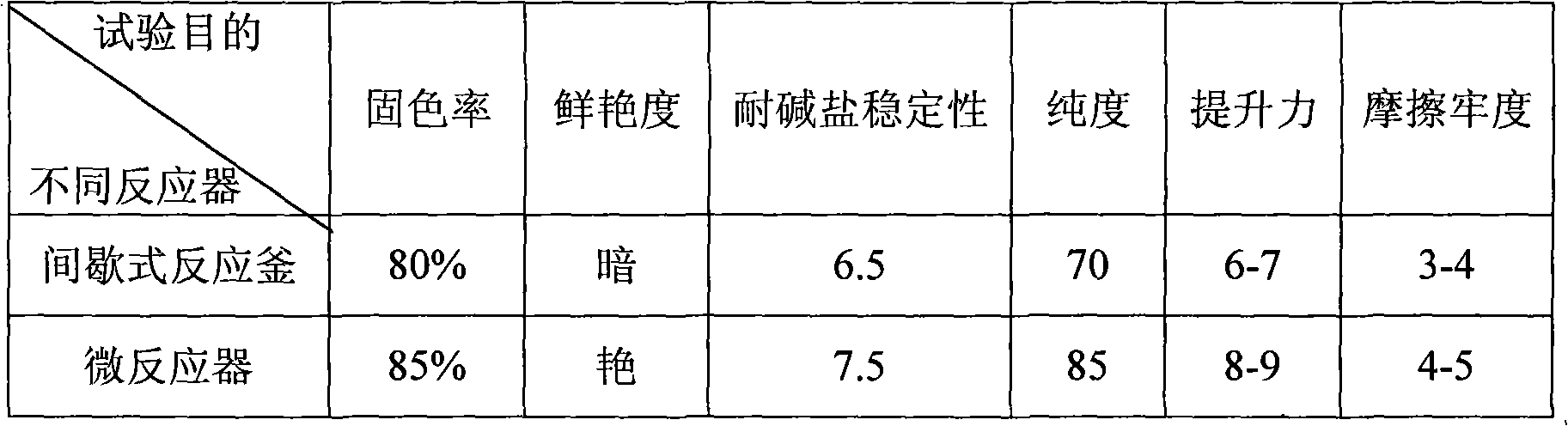

The invention discloses a method for preparing active dye, namely active deep-red C-D by utilization of a microreactor, comprising the following steps that: J acids are coupled with diazonium salts of ethyl sulfone sulfate ester aniline compounds which contain sulfonic group, methyl, methoxyl group, ethyl group or oxyethyl group, and then active deep-red C-D azo dye is obtained; the coupling temperature is between10 and 25 DEG C and the pH value is equal to 1.5 - 6.5; the microreactor is adopted during the reaction process; a plurality of parallelly connected microchannels with diameter of between 10 and 500 micrometers are arranged inside the microreactor and both ends of the microchannels have shell covers. The product has good vividness, stable performance, good reproduction quality, high dye yield, good deep dyeing property and high fixation rate. The structural formula of the active deep-red C-D is as above, wherein, R1 and R2 are equal to H, SO3H, CH3, OCH3, OC2H5 and C2H5.

Description

A kind of method utilizing microreactor to prepare reactive dye reactive deep red C-D Technical field: The invention relates to a method for preparing reactive dye reactive deep red C-D by using a microreactor. Background technique: As we all know, in the diazotization reaction, diazonium salts are generally unstable and easy to decompose or have side reactions. In conventional batch reactors, it is difficult to ensure that all parts of the reaction are stirred evenly. When the local stoichiometric ratio deviates from the reaction conditions, such as insufficient nitrous acid, high concentration of free amine, etc., various side reactions will occur. The advantage of using a microreactor for the reaction is that since the reaction is carried out continuously, the reaction solution is uniformly mixed in an instant, preventing side reactions caused by local excess. The diazonium salt is easily decomposed in the coupling reaction. Especially when the coupling component is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09B31/02C09B62/00

Inventor 赵卫国苏金奇鞠苏华

Owner 赵卫国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com