Nonpoisonous deratization granule and its preparation method and application

A granule, rodent control technology, applied in rodenticides, botanical equipment and methods, chemicals for biological control, etc. Cost and other issues, to achieve the effect of convenient preparation, good rodent control effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

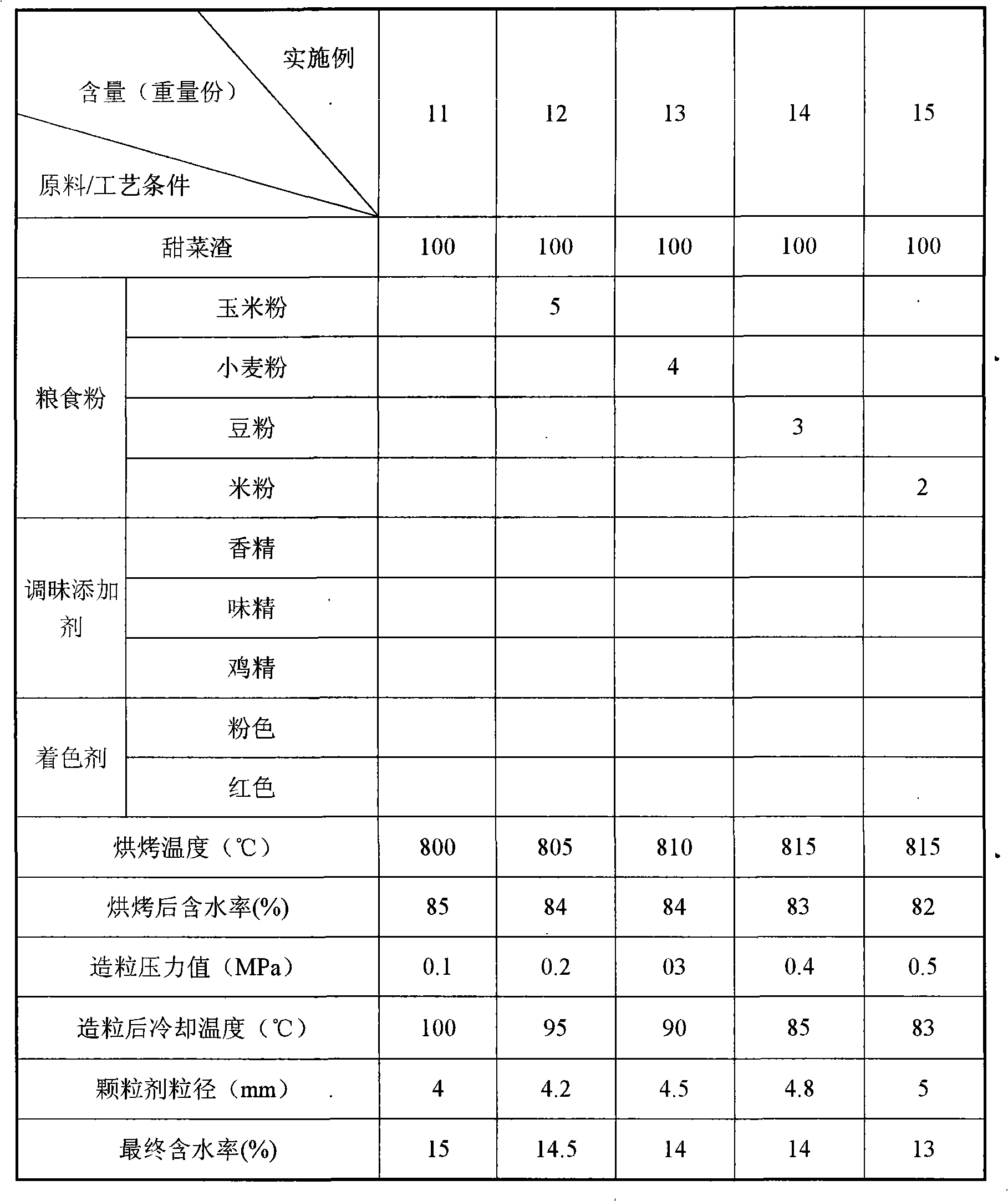

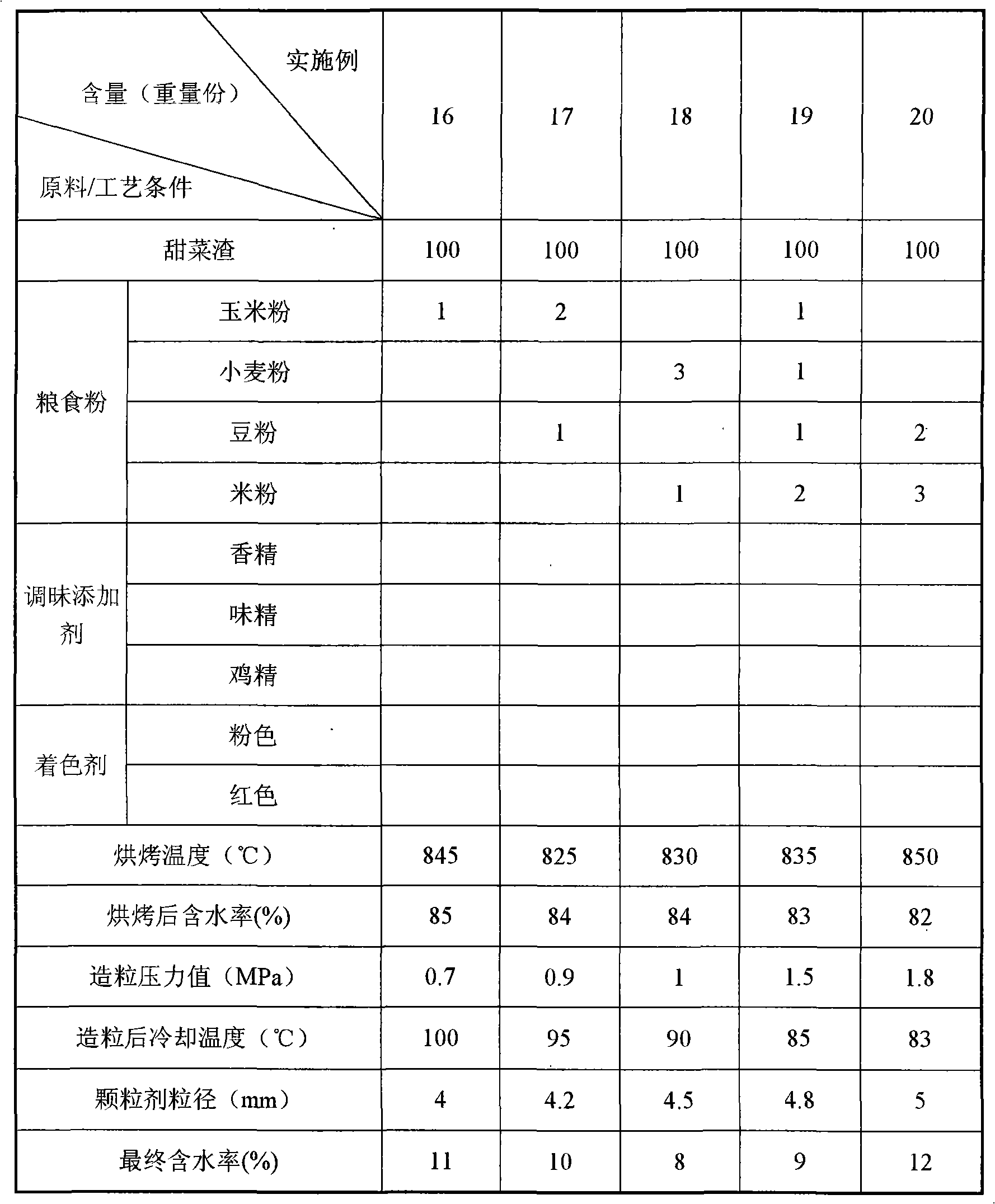

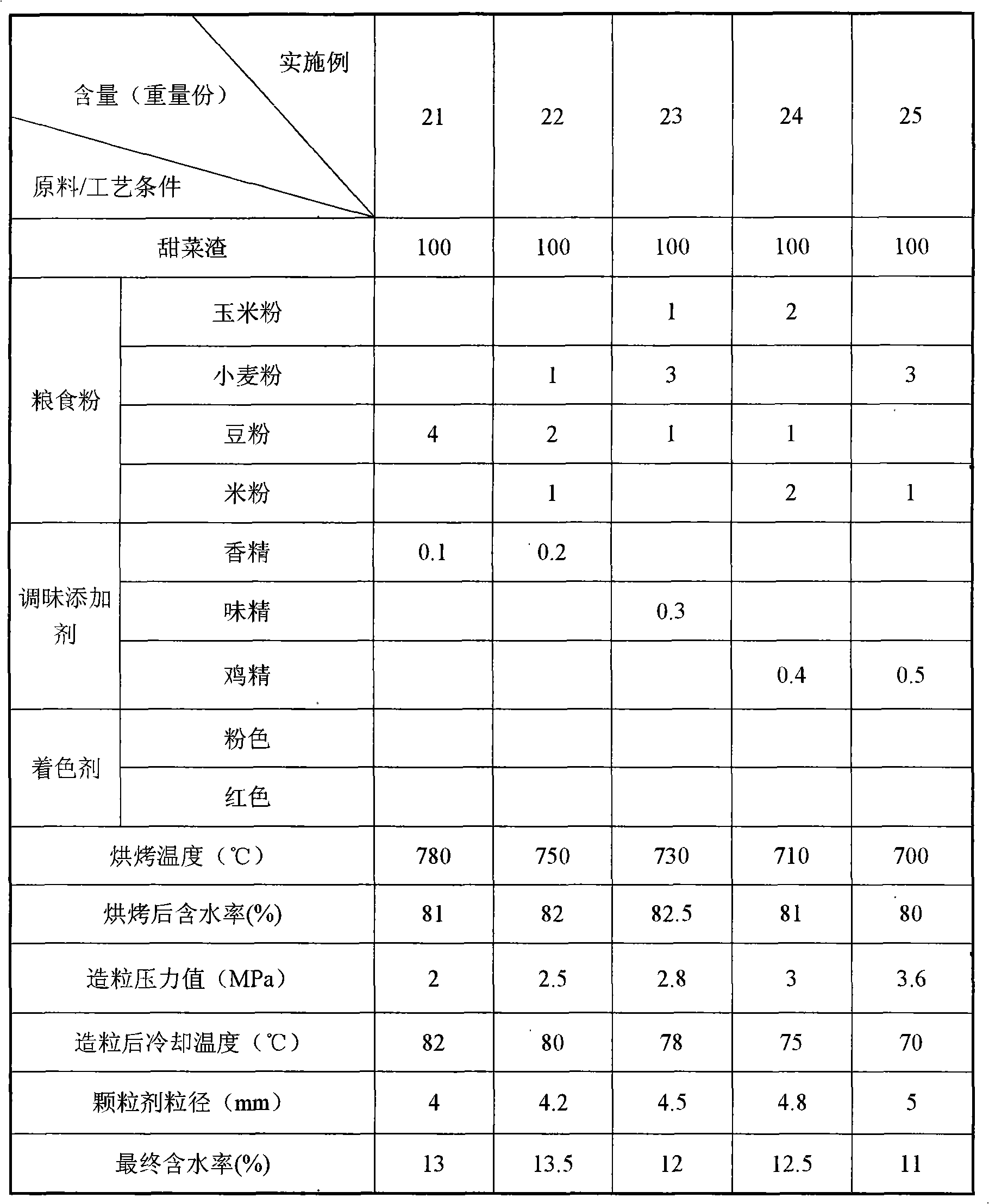

Examples

Embodiment 1

[0011] Example 1: A non-toxic rat-killing granule, mainly using sugar beet pulp after sugar extraction as the processing raw material, baking the beet pulp under steam at a temperature of 800°C until the water content is 85%, and then drying it under 0.1MPa Granulate to make a particle size of 4 mm, then cool to a temperature of 100°C, and dry to a moisture content of 15% in the process of gradually lowering the temperature.

Embodiment 2

[0012] Embodiment 2: A kind of non-toxic rodent control granule, mainly take sugar beet pulp after extracting sugar as processing raw material, bake under the steam of 810 ℃ temperature to moisture content 84%, every 100 weight parts of raw materials are added 1 The corn flour in parts by weight is stirred evenly, and then granulated under 1 MPa to make the particle size is 4.4 mm, then cooled to 100° C., and dried until the water content is 14%.

Embodiment 3

[0013] Embodiment 3: A kind of non-toxic rodent control granule, mainly take sugar beet pulp after extracting sugar as processing raw material, bake under the steam of 830 ℃ temperature to moisture content 83%, every 100 weight parts of raw materials are added 3 Wheat flour in parts by weight is stirred evenly, then granulated at 2 MPa to make a particle size of 4.6 mm, then cooled to 90° C., dried to a moisture content of 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com