Process for preparing bromoundecanoic acid by tower type addition of undecylenic acid

A technology of undecanoic acid and enoic acid tower, which is applied in the preparation of carboxylate, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of large project investment, poor economic benefits, intermittent operation, etc., and achieve good investment returns , easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

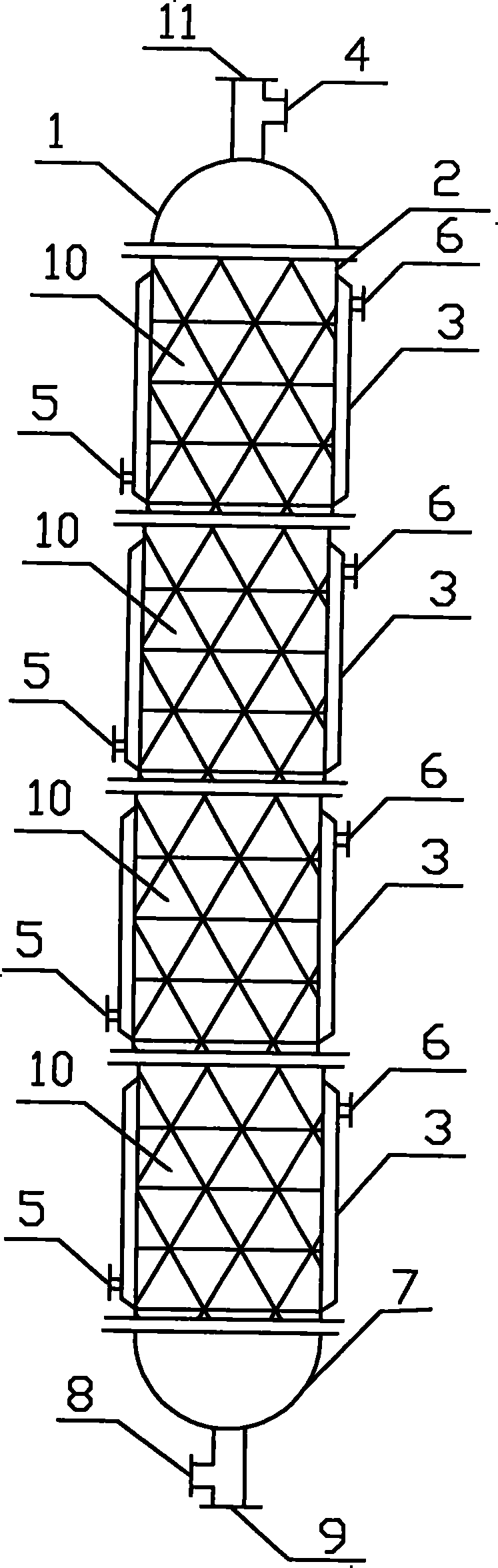

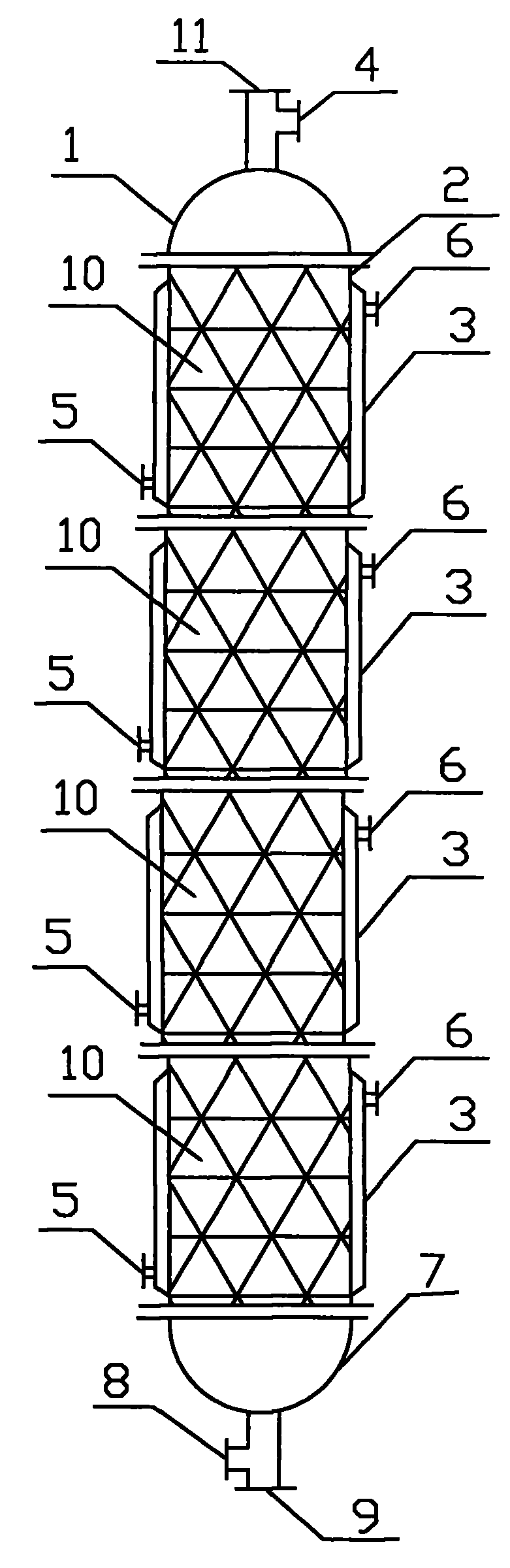

Image

Examples

Embodiment 1

[0013] A method for preparing bromoundecanoic acid by tower bromine addition of undecylenic acid, using a reaction tower with a raw material upper inlet and a raw material lower inlet, the ceramic structured packing with a porosity of 60% is housed in the reaction tower, and the ten Undecylenic acid and toluene liquid are formulated into undecylenic acid toluene solution at a mass ratio of 1:3.5, and then sprayed into the tower from the top of the tower, and hydrogen bromide gas is continuously fed from the bottom of the tower at the same time. The two materials are ten The molar ratio of monoenoic acid to hydrogen bromide is 1:1.1. Under the condition of controlling the reaction temperature at 20-30°C, continuous reverse contact occurs to generate bromoundecanoic acid solution, which is then fed into bromoundecanoic acid solution from the bottom of the reaction tower. Acid and toluene separation process, that is, bromoundecanoic acid product.

Embodiment 2

[0015] A method for preparing bromoundecanoic acid by tower bromine addition of undecylenic acid, using a reaction tower with a raw material upper inlet and a raw material lower inlet, the ceramic structured packing with a porosity of 60% is housed in the reaction tower, and the ten Undecylenic acid and toluene liquid are made into undecylenic acid toluene solution in a mass ratio of 1:3, and then sprayed into the tower from the top of the tower, and hydrogen bromide gas is continuously fed from the bottom of the tower at the same time. The two materials are ten The molar ratio of monoenoic acid to hydrogen bromide is 1:1.0. Under the condition of controlling the reaction temperature at 20-30°C, continuous reverse contact occurs to generate bromoundecanoic acid solution, which is then fed into bromoundecanoic acid solution from the bottom of the reaction tower. Acid and toluene separation process, that is, bromoundecanoic acid product.

Embodiment 3

[0017] A method for preparing bromoundecanoic acid by tower bromine addition of undecylenic acid, using a reaction tower with a raw material upper inlet and a raw material lower inlet, the ceramic structured packing with a porosity of 60% is housed in the reaction tower, and the ten Undecylenic acid and toluene liquid are made into undecylenic acid toluene solution at a mass ratio of 1:4, and then sprayed into the tower from the top of the tower, and hydrogen bromide gas is continuously fed from the bottom of the tower at the same time. The two materials are ten The molar ratio of monoenoic acid to hydrogen bromide is 1:1.5. Under the condition of controlling the reaction temperature at 20-30°C, continuous reverse contact occurs to generate bromoundecanoic acid solution, which is then fed into bromoundecanoic acid solution from the bottom of the reaction tower. Acid and toluene separation process, that is, bromoundecanoic acid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com