Balance mass movement device based on five-rod device and its control method

A technology of balancing mass and five-bar mechanism, applied in electric controller, control using feedback, exposure device in photoengraving process, etc., it can solve the problems that ordinary linear motors do not have, and achieve high control accuracy, compensation and offset additional rotation. Moment, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

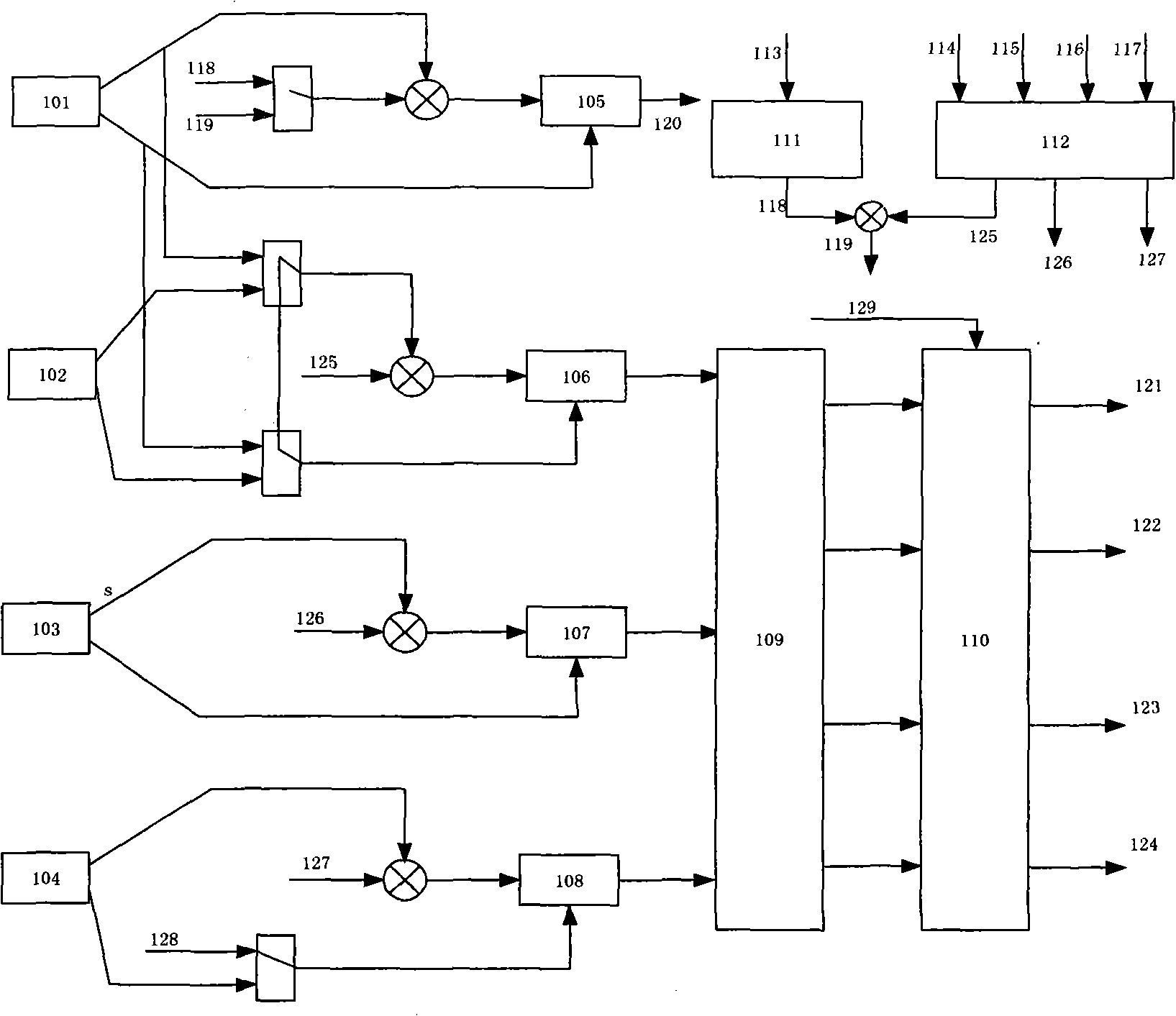

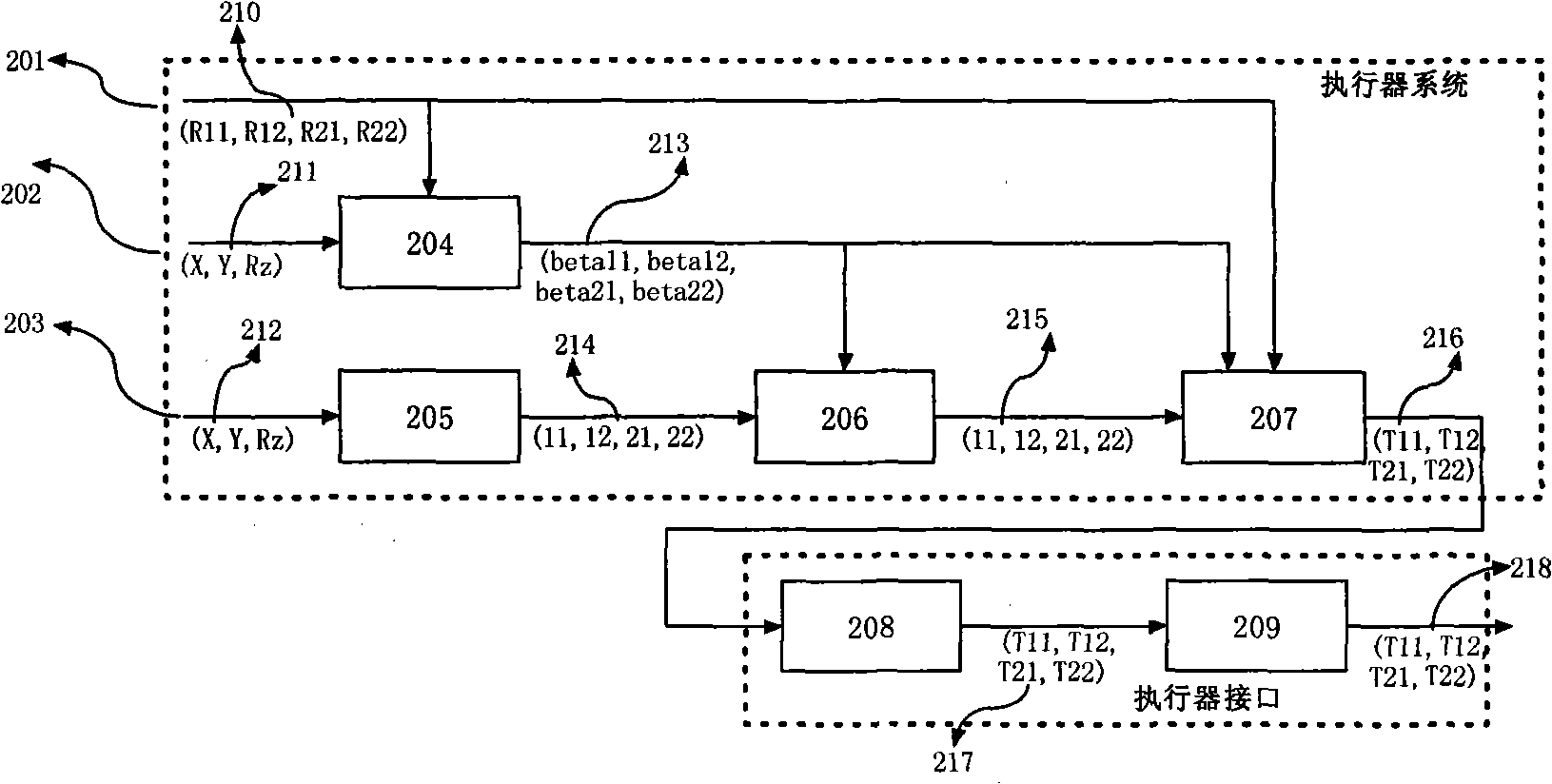

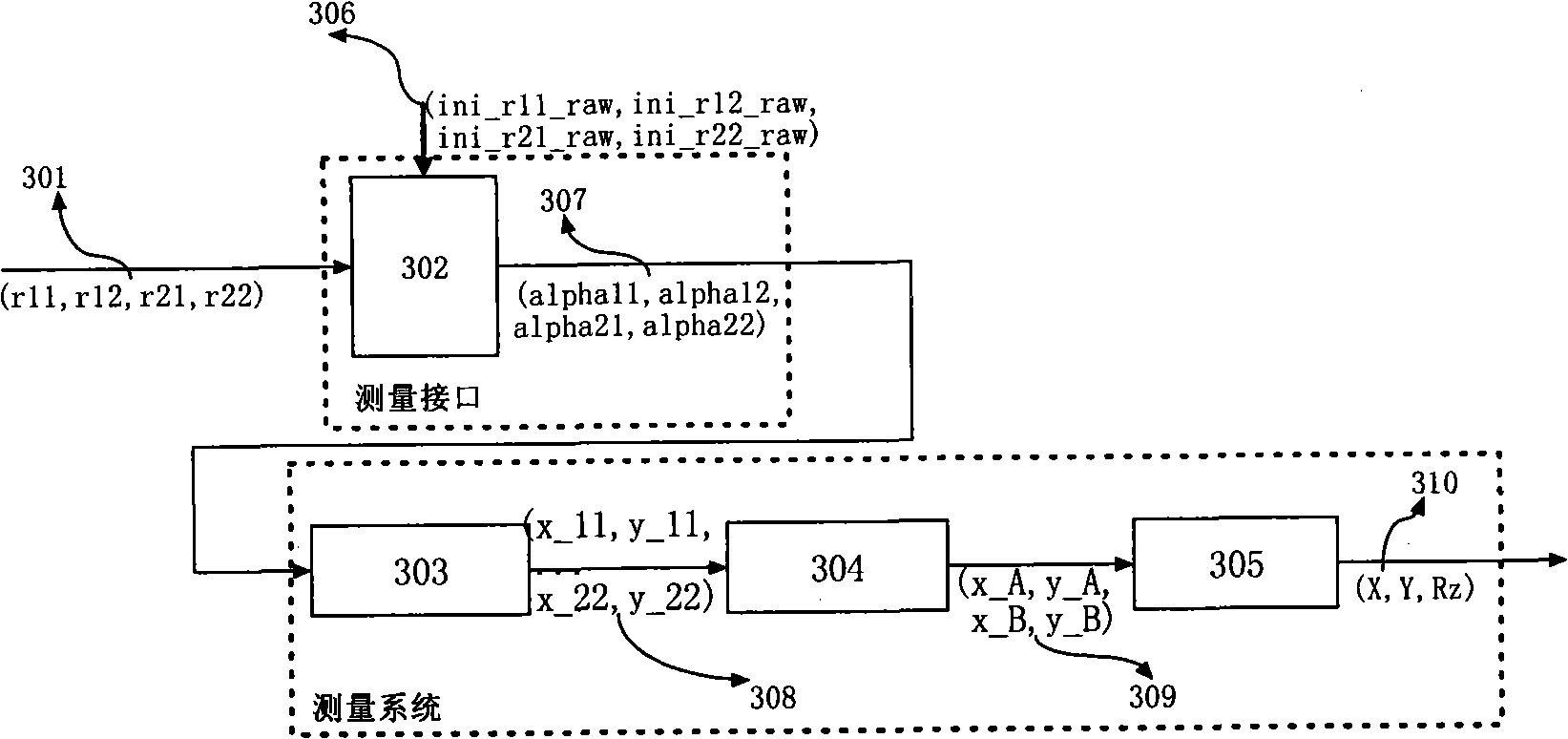

[0046] Such as figure 1 As shown, the control strategy of the balance mass positioning control system is designed based on the optimized double-crank five-bar linkage motion actuator. The present invention provides two control modes: independent motion mode and following motion mode. In the independent motion mode, the balance mass can realize single-axis motion with X / Y / Rz degrees of freedom according to its own independent trajectory planning. Module 112 in the figure will realize the absolute coordinate measurement of the bottom balance mass, and module 111 will realize the relative displacement measurement of the long-stroke load relative to the bottom balance mass. Module 101 is a long-stroke X-direction set value generator that realizes the X-direction motion control of the silicon wafer carrier through the controller 105; the balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com