Method and device for measuring free calcium oxide in cement or coal ash by microwave heating

A technology of free calcium oxide and microwave heating, which is used in the field of microwave heating to measure free calcium oxide in cement or fly ash, which can solve the problem that the production line cannot adjust the composition in time, the dissolution efficiency of free calcium oxide is low, and the service life of the electric heating wire is short, etc. problems, to achieve the effect of reducing the number of dissolutions, fast heating, and long service life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] (1) Preparation of eluate

[0024] The dissolution solution of free calcium oxide in cement or fly ash can be a mixture of glycerol, ethylene glycol or ethylene glycol ethanol, which is consistent with the traditional dissolution medium of free calcium oxide. Usually ethylene glycol-ethanol mixture is used after mixing according to the volume ratio of 2:1;

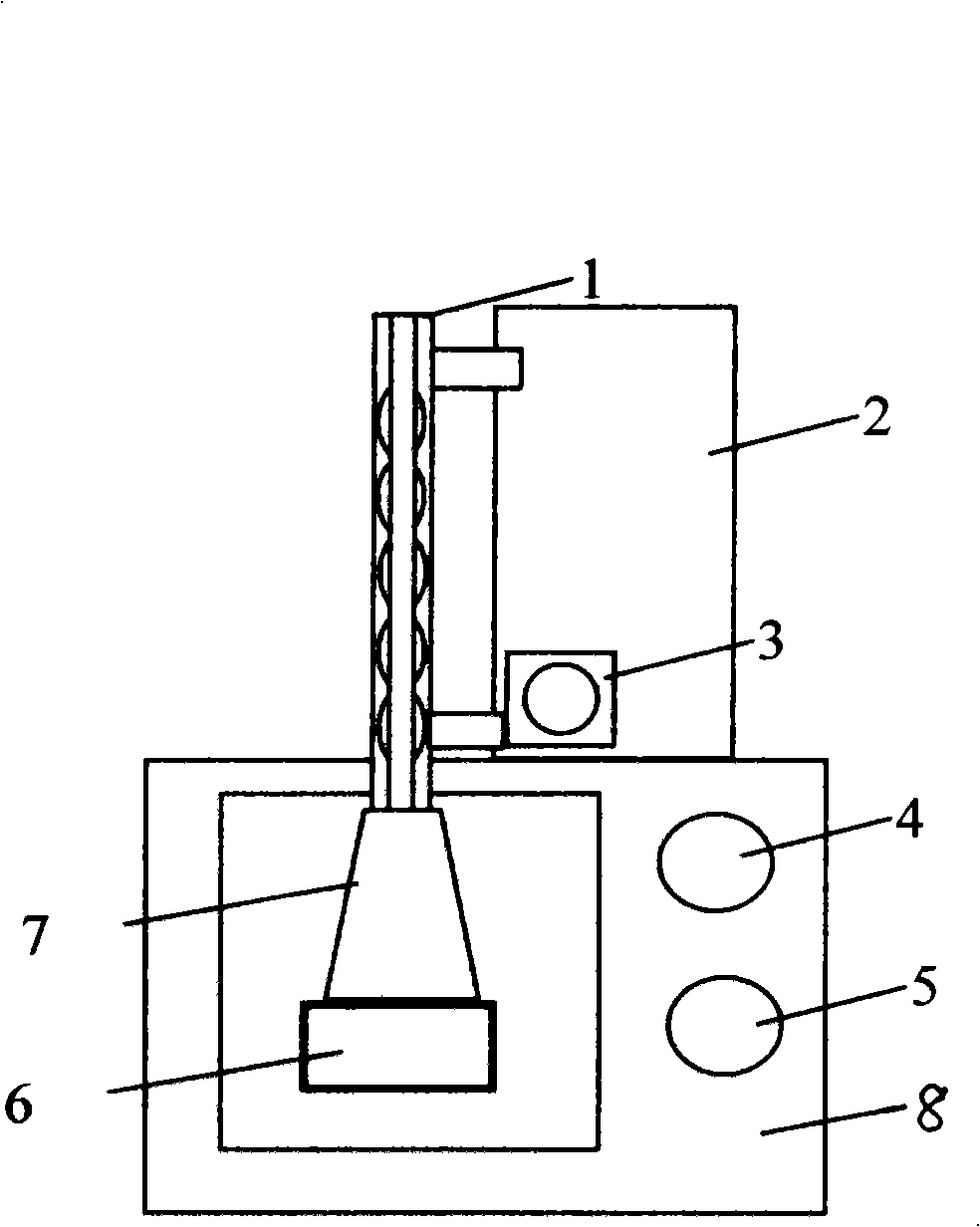

[0025] (2) Put 0.3g to 0.5g of weighed cement or fly ash in a flask with a ground mouth (or a conical flask with a ground mouth), and then add an indicator that has been treated with sodium hydroxide in advance. 18 ml to 22 ml of ethylene glycol-ethanol mixture, and place the ground flask in a household microwave oven. A hole is made on the top of the household microwave oven, and the glass serpentine condenser tube passes through it to connect with the ground flask placed in the microwave oven hall;

[0026] (3) Set the heating time for 2 to 5 minutes, the heating power is greater than 450 watts, turn on the micr...

Embodiment 1

[0032] Take 0.4065 grams of cement with a fineness of 10.4% (85 micron sieve), add 20 milliliters of ethylene glycol-ethanol solution, put it in a ground conical flask, select 70% of the microwave power of 1 kilowatt, and heat it by microwave for 3 minutes , and then titrated with standard benzoic acid solution, the measured free calcium oxide content was 3.54%, and the standard method error was -0.01%.

Embodiment 2

[0034] Get 0.4143 grams of cement fineness of 10.4% (85 micron sieve), add 20 milliliters of ethylene glycol-ethanol solution, place the ground conical flask, select 50% of the microwave power of 1 kilowatt, heat for 4 minutes, and then Titrated with standard benzoic acid solution, the measured free calcium oxide content was 3.56%, and the standard method error was +0.01%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com