Method for surface in situ synthesis of conductive polyaniline PANi by using four acicular type zinc oxide crystal whisker T-ZnOw

A technology of four-needle zinc oxide and conductive polyaniline is applied in the fields of material modification, conductive polymers and inorganic composite materials to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

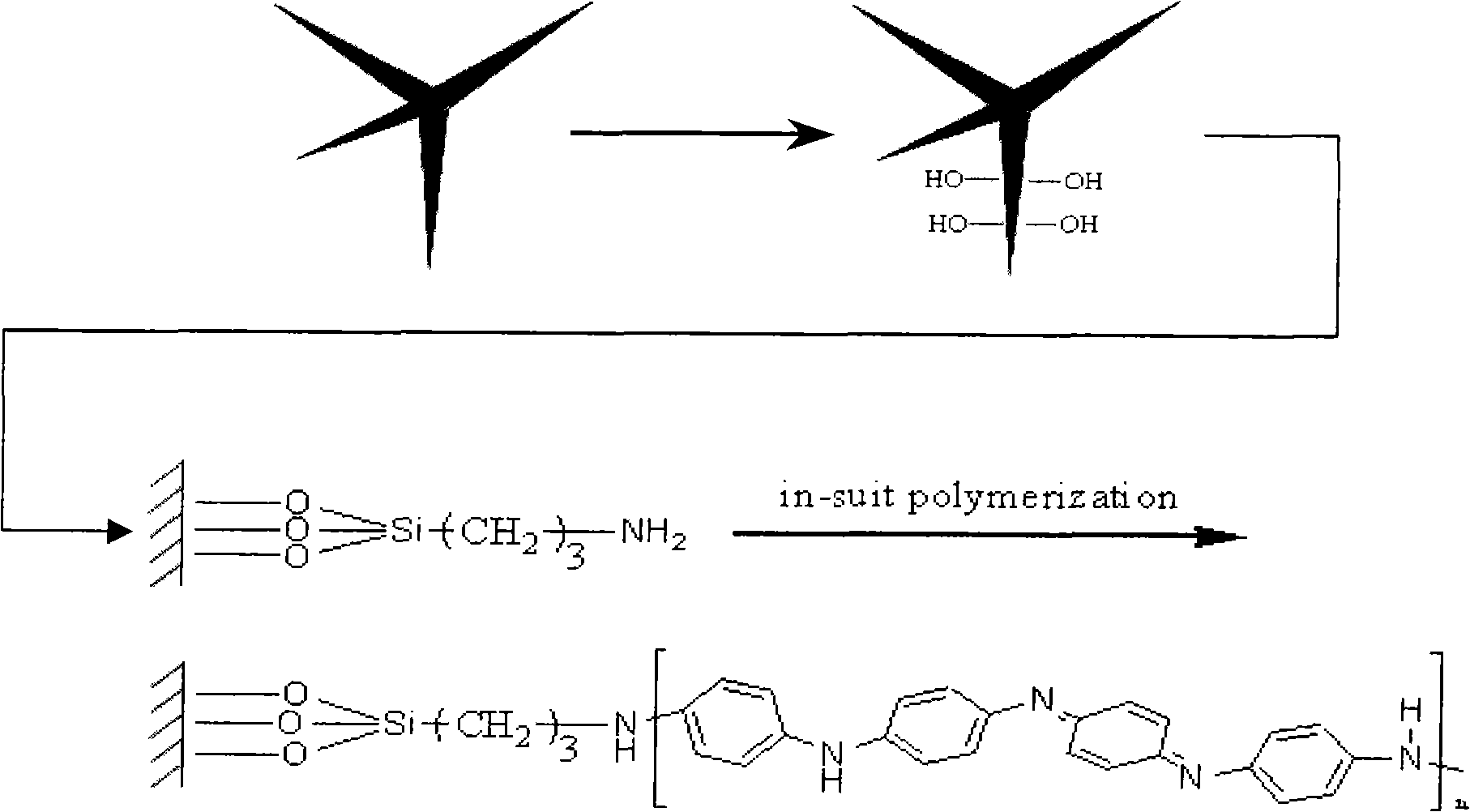

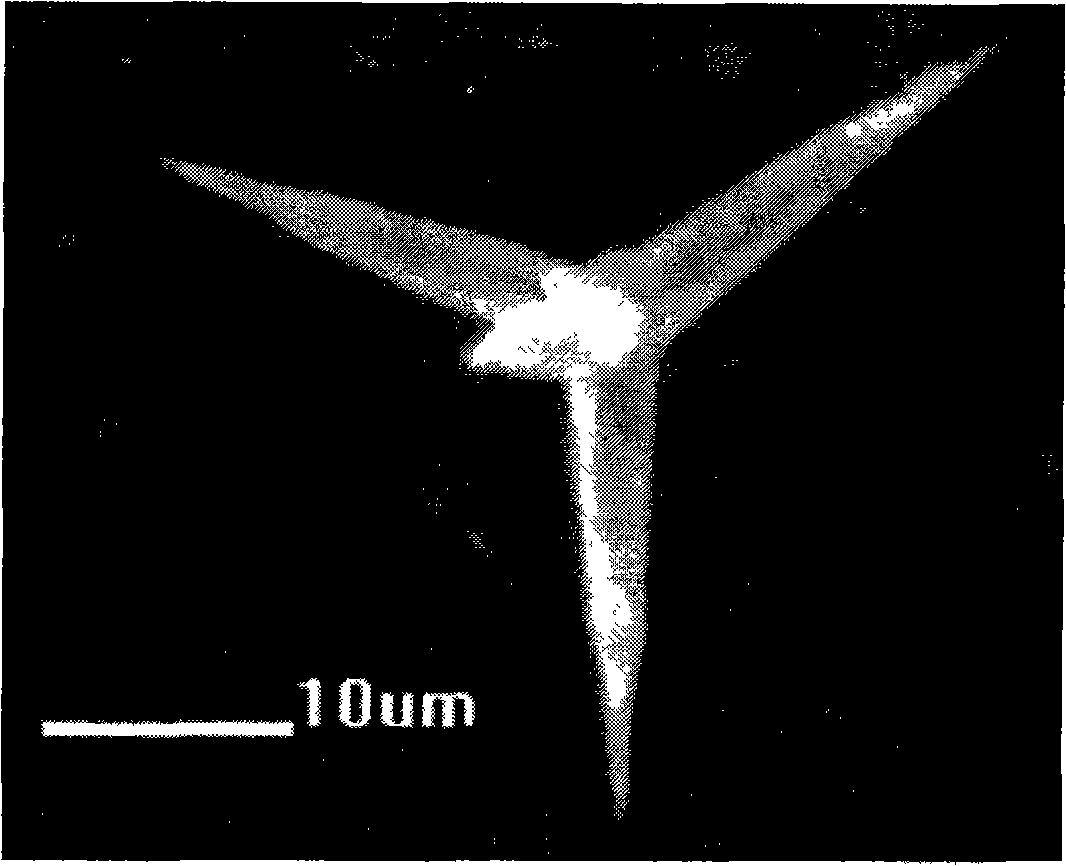

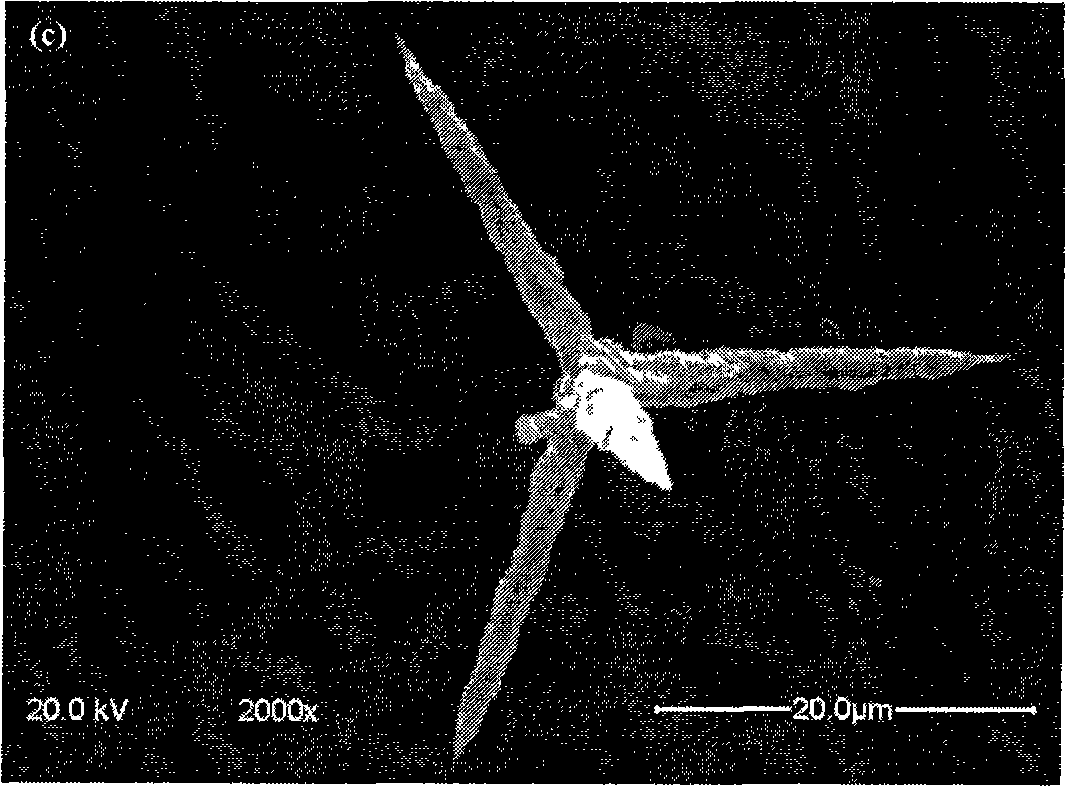

[0020] 1. Dry 10 g of tetrapod-like zinc oxide whiskers in a blast drying oven at a constant temperature of 120°C for 4 hours.

[0021] 2. Disperse the above-mentioned dried T-ZnOw into 100mL of absolute ethanol solution, then add 0.3g of silane coupling agent (KH-550), stir for 1h, then raise the temperature to 80°C, stir and reflux at constant temperature for 10h. After the reaction was finished, it was washed repeatedly with absolute ethanol and distilled water, and the product was placed in an oven at 80°C after suction filtration, and dried at a constant temperature for 24 hours.

[0022] 3. Add 200mL of absolute ethanol solution to the T-ZnOw treated in step 2, then add 4.8ml of aniline monomer, 10mL of 0.5mol / L hydrochloric acid solution, stir in an ice-water bath for 30min, and cool it down to 2°C; Weigh 14.7g of ammonium persulfate and add 50ml of distilled water to fully dissolve it; add the prepared ammonium persulfate aqueous solution drop by drop to the above reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com