Intercalation polymerization polylactic acid-organophilicsoapstone composite material and preparation thereof

A technology of organic saponite and composite materials, which is applied in the field of intercalation polymerized polylactic acid-organic saponite composite materials and its preparation, can solve problems such as deformation and heat resistance limiting applications, expand the scope of application, and facilitate industrialization The effect of simple production and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

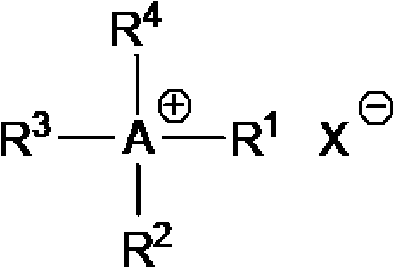

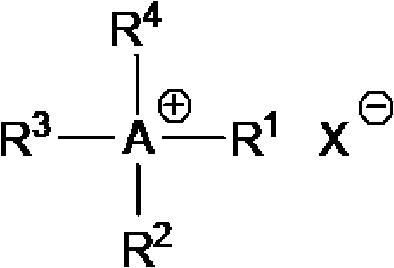

[0023] Embodiment 1: Stir 100 grams of raw material soapstone in 1000 grams of deionized water to form a stable suspension with a concentration of 10% by mass; prepare 0.141 moles of organic cationic salt cetyltrimethylammonium chloride in deionized water into a 2% mass percent concentration solution. Stir the soapstone suspension at 90°C for 30 minutes at a stirring speed of 1000 rpm, then add the above-mentioned organic cation salt cetyltrimethylammonium chloride solution to the above-mentioned soapstone suspension, and react for 4 hours, Then filter. And the filtrate is washed several times with deionized water, and is detected by 0.1 mol / liter silver nitrate solution until there is no halogen ion in the washing liquid; the organic saponite after washing is dried and ground to obtain a particle size of 60 microns to 74 microns of organic saponite.

[0024] Preparation of intercalation polymerized polylactic acid-organized saponite composite material: Take 100 parts by wei...

Embodiment 2

[0025] Embodiment 2: 100 grams of raw material soapstone are stirred in 2000 grams of deionized water to form a stable suspension with a concentration of 5% by mass; 0.1194 moles of organic cationic salt dioctadecyldimethylammonium chloride are dissolved in deionized water Prepared as a 5% mass percent concentration solution. Stir the soapstone suspension at 80°C for 15 minutes at a stirring speed of 900 rpm, then add the above-mentioned organic cation salt dioctadecyldimethylammonium chloride solution to the above-mentioned soapstone suspension and react for 3 hours , and then filter. And the filtrate is washed several times with deionized water, and is detected by 0.1 mol / liter silver nitrate solution until there is no halogen ion in the washing liquid; the organic saponite after washing is dried and ground to obtain a particle size of 60 microns to 74 microns of organic saponite.

[0026] Preparation of intercalation polymerized polylactic acid-organized saponite composit...

Embodiment 3

[0027]Embodiment 3: 100 grams of raw material soapstone are stirred in 3500 grams of deionized water to form a stable suspension with a concentration of 2.86% by mass; 0.1 mole of organic cationic salt dioctadecyldimethylammonium chloride is mixed with octadecane 0.1 mole of trimethylammonium chloride was prepared in deionized water to prepare a solution with a concentration of 6% by mass. Stir the soapstone suspension at 70°C for 10 minutes at a stirring speed of 400 rpm, then mix the above organic cation salt dioctadecyldimethylammonium chloride and octadecyltrimethylammonium chloride The solution was added to the above soapstone suspension, reacted for 2 hours, and then filtered. And the filtrate is washed several times with deionized water, and is detected by 0.1 mol / liter silver nitrate solution until there is no halogen ion in the washing liquid; the organic saponite after washing is dried and ground to obtain a particle size of 60 microns to 74 microns of organic sapon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com