Repel push magnetic body component, complete permanent magnetism complete suspending bearing as well as combined wind power photovoltaic power generation system

A magnet assembly, permanent magnet technology, applied in photovoltaic power generation, wind power generation, magnetic bearings, etc., can solve the problems of discontinuous power generation, support vibration, low efficiency of wind power generation system, etc., to reduce vibration, eliminate friction, and reduce start-up The effect of wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

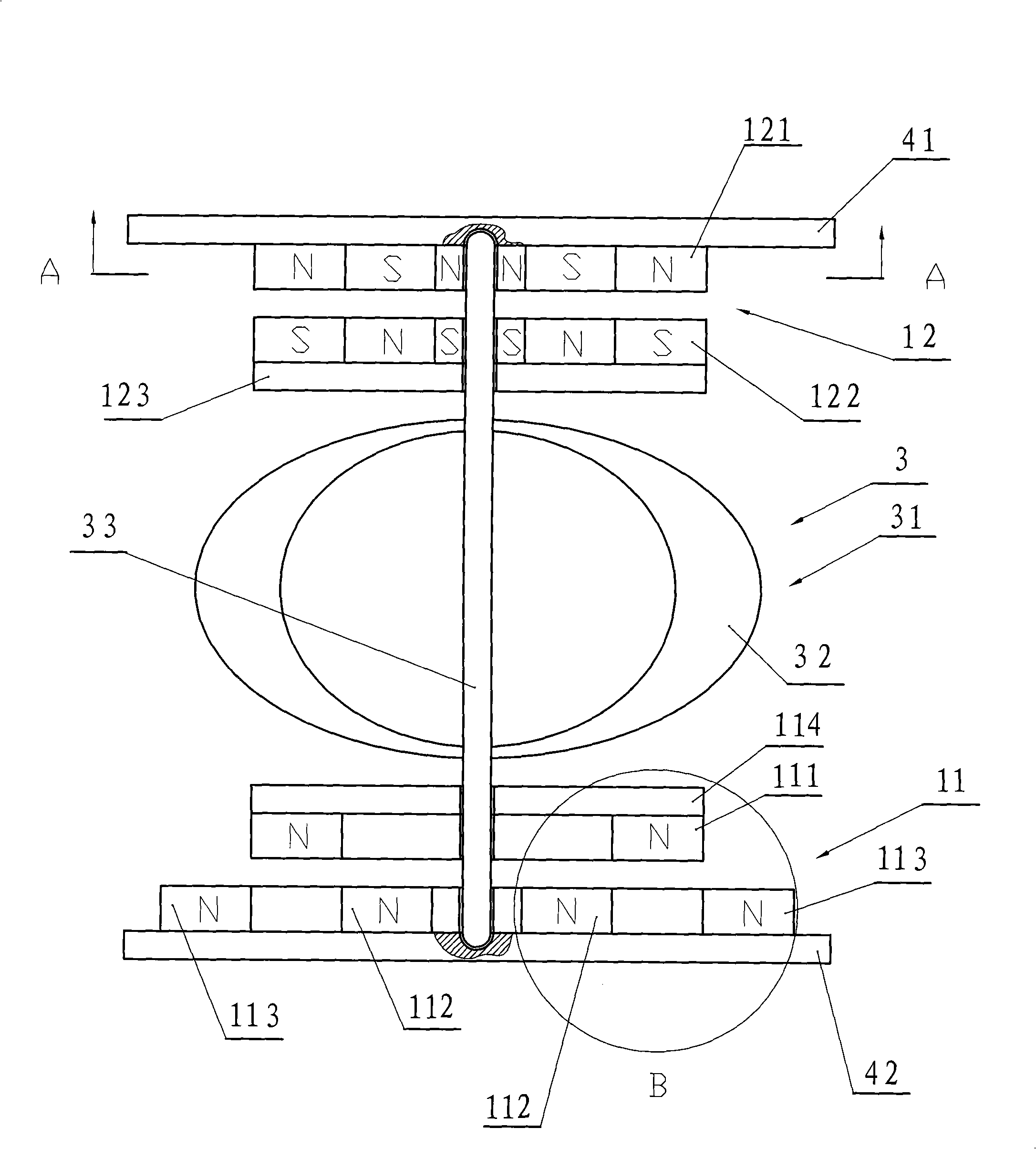

[0035] figure 1 The vertical shaft wind power generator is provided with a full permanent magnet full suspension bearing composed of a repelling magnet assembly 11 and a pull-push magnet assembly 12. Column 43 ( figure 1 Not shown in the middle), the fixed bracket, the generator 2 ( figure 1 not shown) or the generator 2 ( figure 1 Not shown), the wind turbine 3 includes a vertical shaft rotating body 31, the rotating body 31 of this embodiment is composed of a vertical shaft impeller 32 and a main shaft 33, and can also be other forms of rotating body, such as a rotating body that only includes a vertical shaft type impeller 32 .

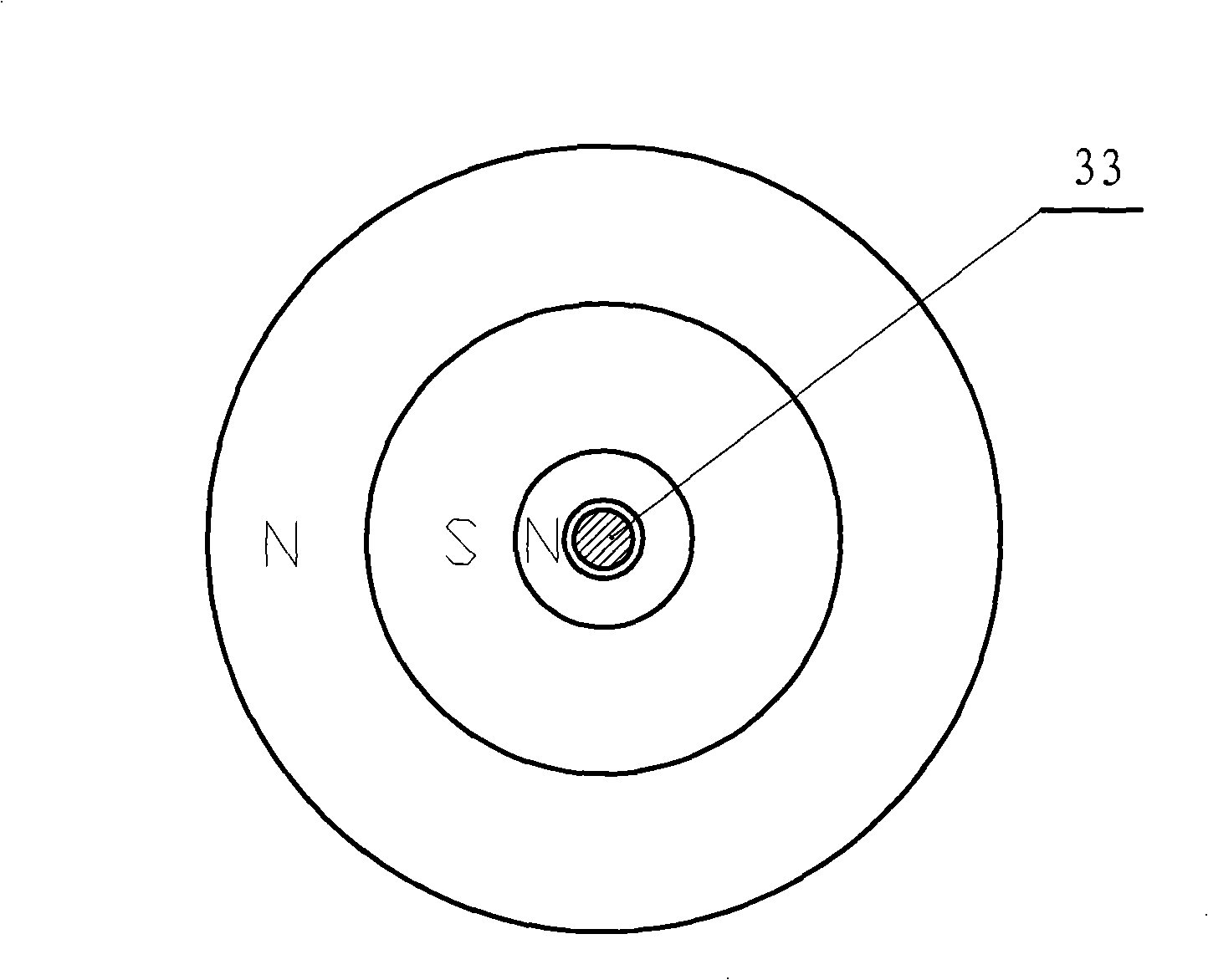

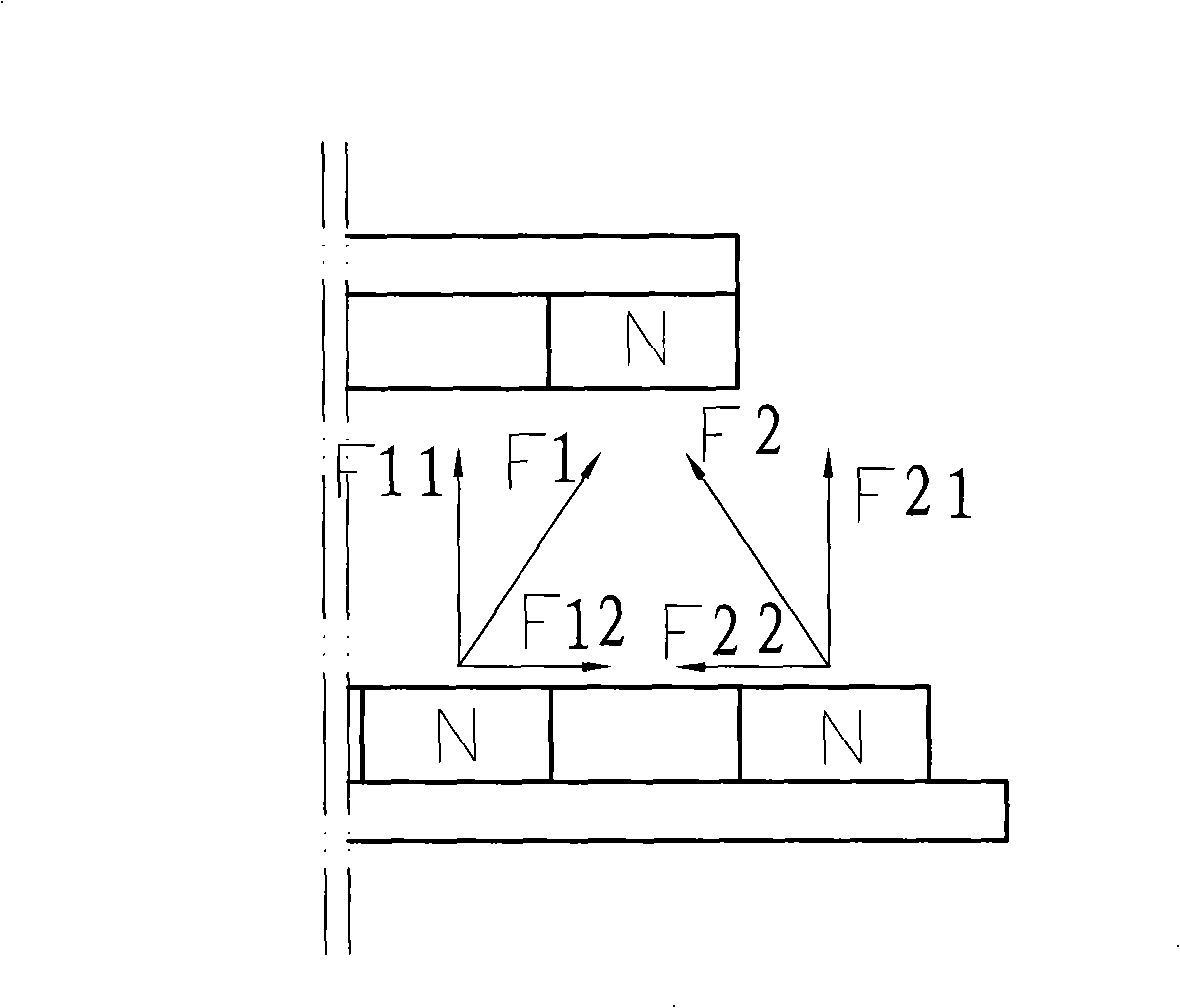

[0036] Wherein the repulsion magnet assembly 11 is arranged on the vertical main shaft 33, including the coaxial center with the main shaft 33, the repulsion upper body and the repulsion lower body arranged at a certain distance up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com