Chain for use in automobile engine

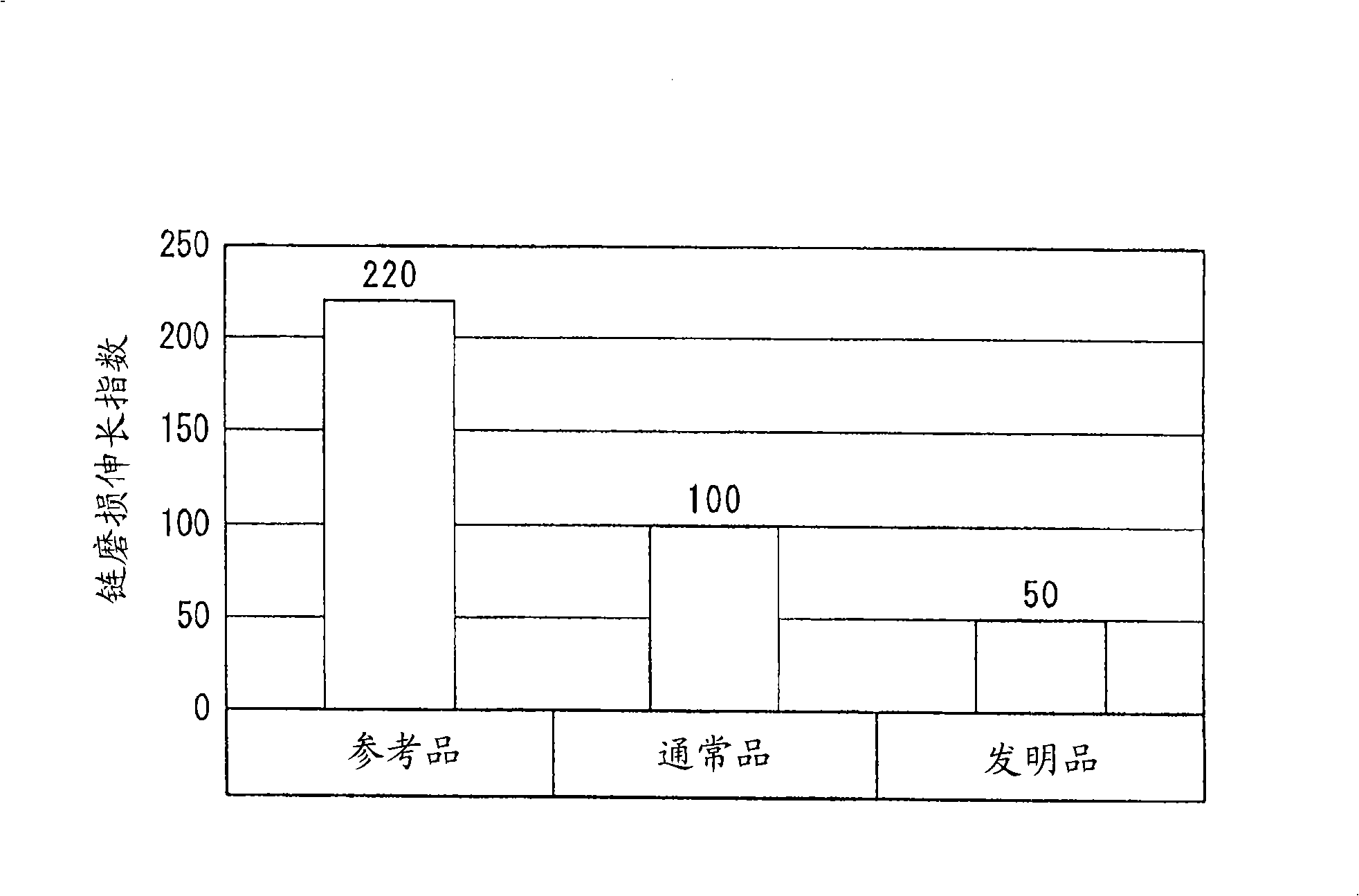

A technology of automobile engine and sleeve, applied in the direction of machine/engine, transmission chain, mechanical equipment, etc., can solve the problems of wear, easy to be affected by oxidation and corrosion, short life, etc., to improve wear resistance and inhibit oil film Effects of improved fracture and roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

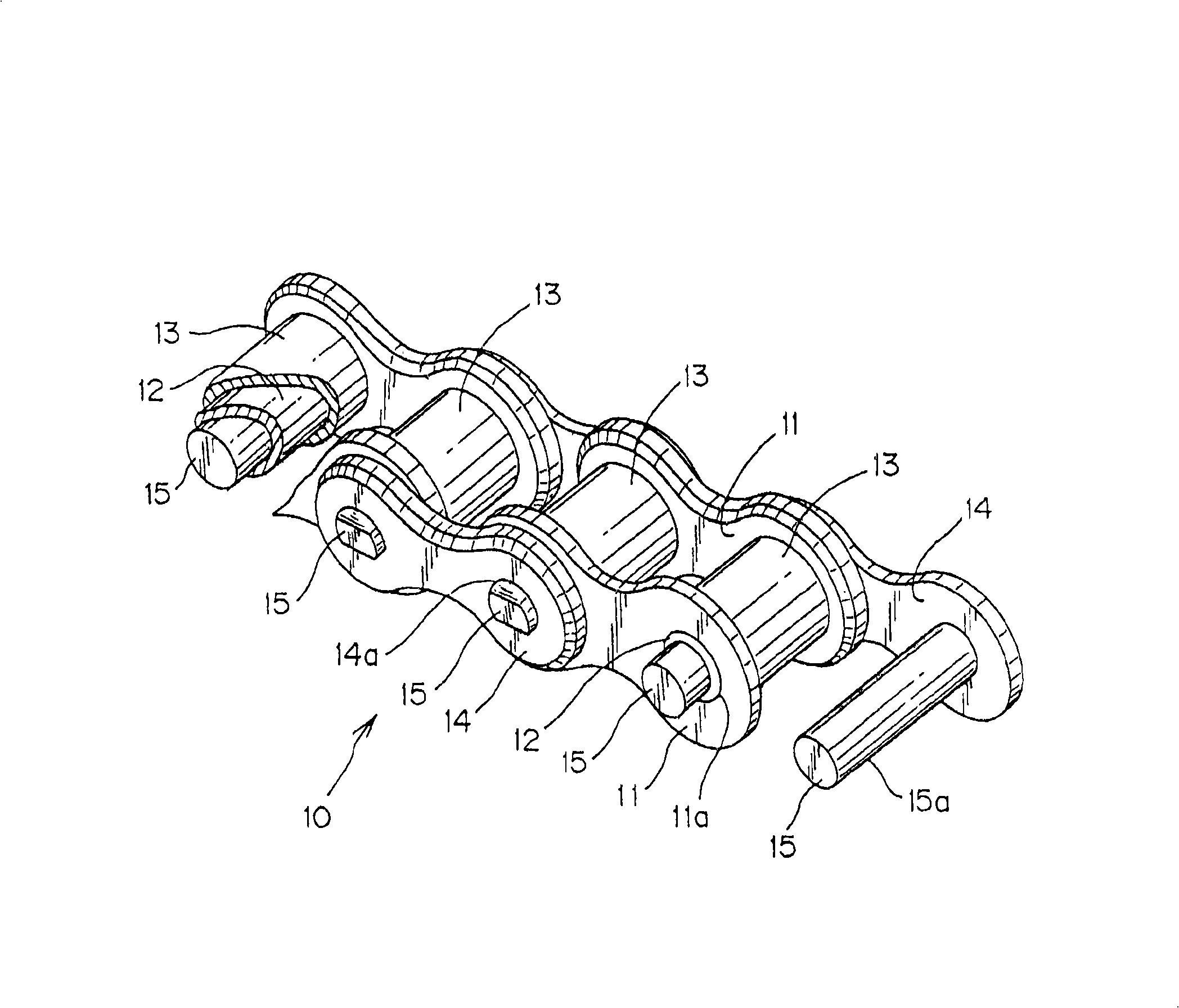

[0025] refer to Figure 1 to Figure 3 , the embodiments of the present invention will be described based on examples. In addition, as can be seen from the above description, since the present invention aims at improving the characteristic deterioration caused by the sliding contact between the inner surface of the bush and the outer surface of the pin, the effect is exhibited regardless of whether it is a roller chain or a bush chain. essentially the same trend. Therefore, in the description of the following embodiment, it demonstrates based on a roller chain.

[0026] figure 1 It is a perspective view showing a part of a roller chain as an embodiment of the present invention. in the figure 1 In , it is shown with a part cut away to understand the internal structure of the roller chain.

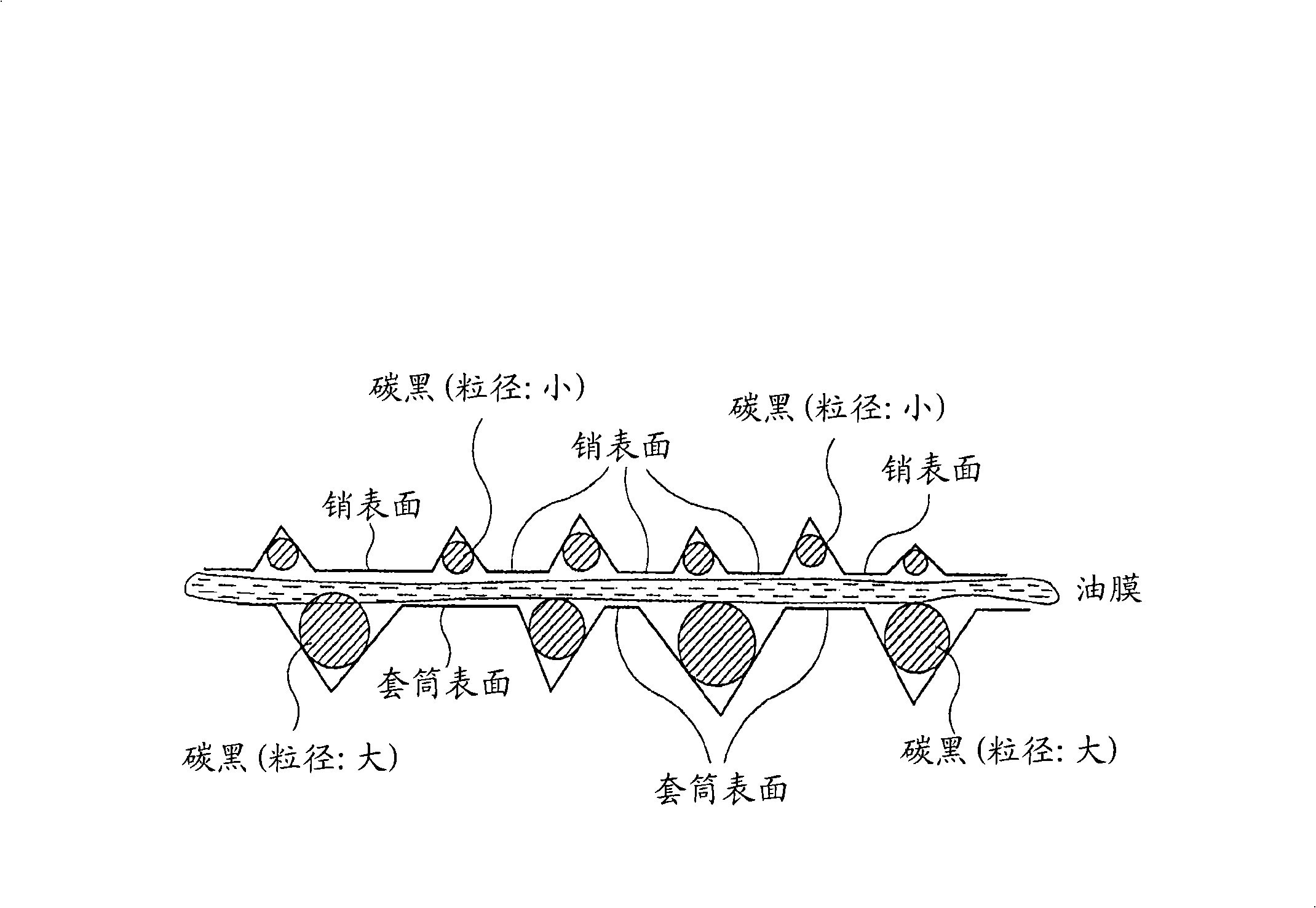

[0027] In the roller chain 10, both ends of the sleeve 12 are respectively pressed into the sleeve holes 11a of the pair of inner plates 11, and both ends of the pin 15 loosely embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com