High-efficiency self-coupling solar hydrogen-system making

A hydrogen production system, self-coupling technology, applied in the field of solar hydrogen production system, can solve the problems of efficiency loss, reduce solar energy-hydrogen conversion efficiency, etc., and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

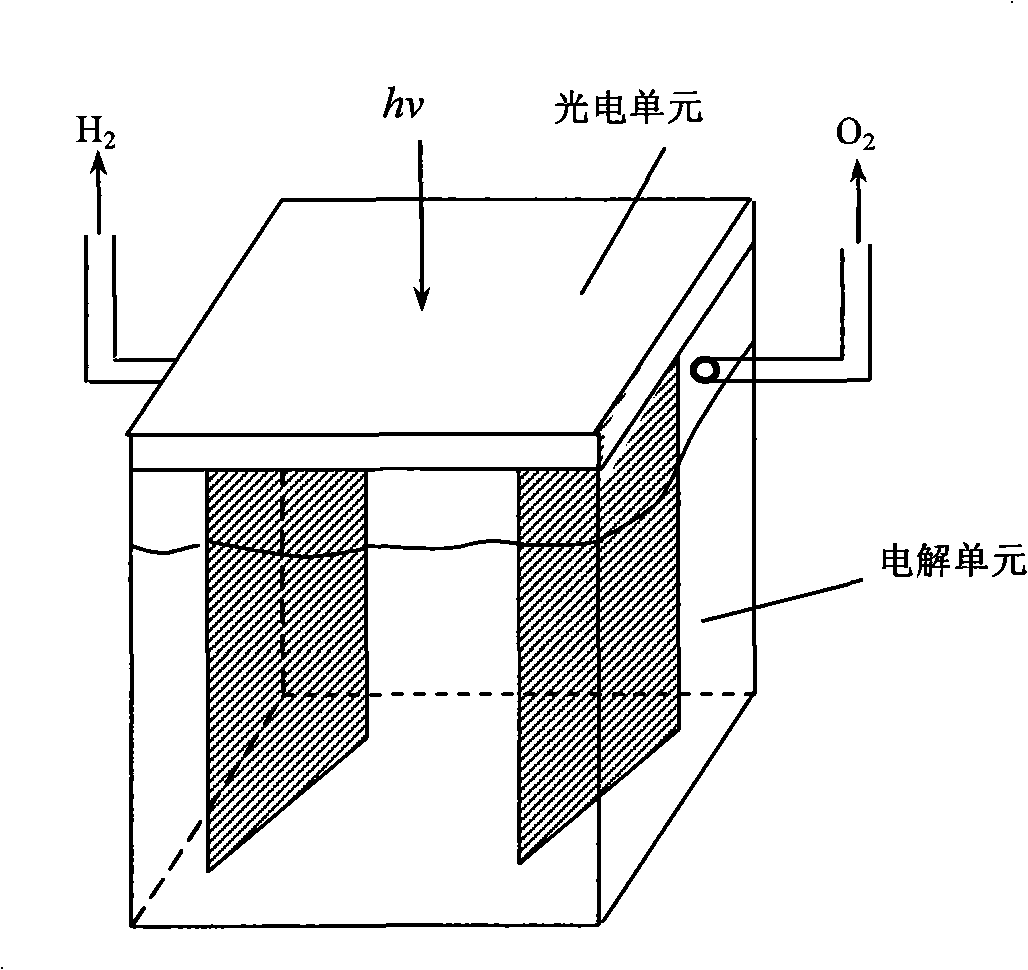

[0020] like figure 1 As shown, the subsystem of the solar hydrogen production system includes a photovoltaic unit (1) and an electrolysis unit (2), and the two are directly connected together to obtain a self-coupling integration to construct a photolysis water hydrogen production subsystem.

[0021] (1) Technical parameters of photoelectric unit

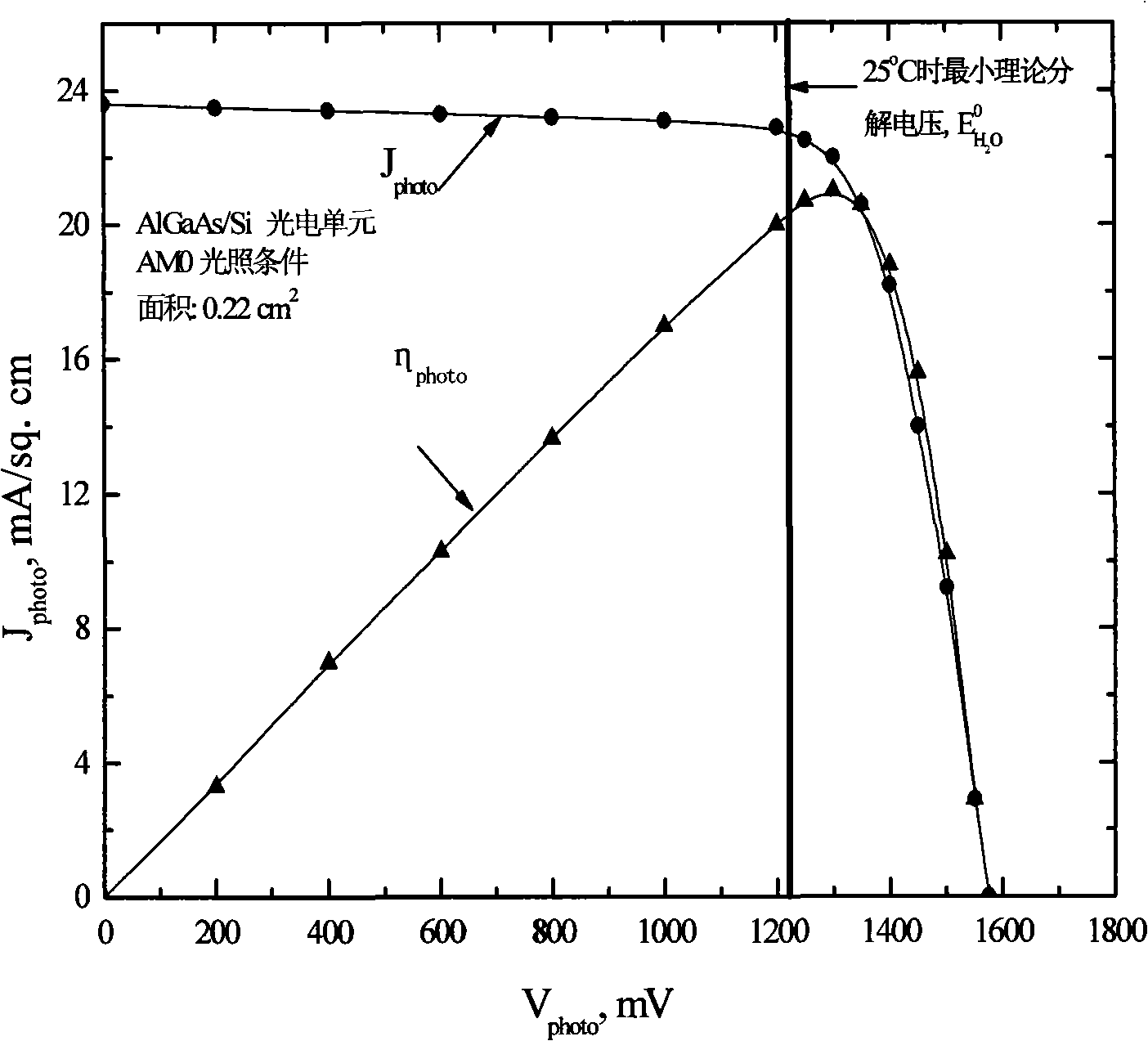

[0022] Composition: Al 0.15 Ga 0.85 As / Si, unit electrode area is 0.22cm 2 .

[0023] Obtain the working curve (I-V) of the photoelectric unit through the I-V curve test system as attached image 3 shown.

[0024] (2) Technical parameters and preparation methods of the electrolysis unit

[0025] Composition: Cathode: Pt black ; Anode: RuO 2 ; Electrolyte: 1M HClO 4 , the unit electrode area is 10cm 2 .

[0026] ① Cathode Pt black Preparation:

[0027] 3g H 2 PtCl 6 and 0.25g Pb(C 2 h 3 o 2 ) 2 Dissolved in 100mL of water to prepare the electroplating solution. The Pt mesh (4cm×4cm) was cleaned with dilute nitric ...

Embodiment 2

[0063] 1. The photoelectric unit is the same as in Embodiment 1.

[0064] 2. The electrolyte in the electrolysis unit is 1M KOH (excellent pure), and the cathode is Pt black , the anode is Ru 0.5 Ce 0.3 sn 0.2 o 2 .

[0065] (1) Cathode Pt black The preparation method is the same as in Example 1.

[0066] (2) Anode Ru 0.5 Ce 0.3 sn 0.2 o 2

[0067] The first step of titanium sheet pretreatment: polish the Ti sheet with a thickness of 200 μm with sandpaper, corrode it with 20% hydrochloric acid for 2 minutes, and wash it with water.

[0068] Take 0.05mol RuCl in the second step 3 -3H 2 O, 0.03molCe(SO 4 ) 2 -4H 2 O, 0.02mol SnCl 2 -2H 2 O, use 20% hydrochloric acid to prepare it into a solution with a total concentration of Ru-Ce-Sn metal ions of 0.1M.

[0069] The third step is to immerse the treated titanium sheet in the prepared solution, evaporate the solvent, bake at 350°C for 15min, repeat the above steps five times, and then bake at 400°C for 1h, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com