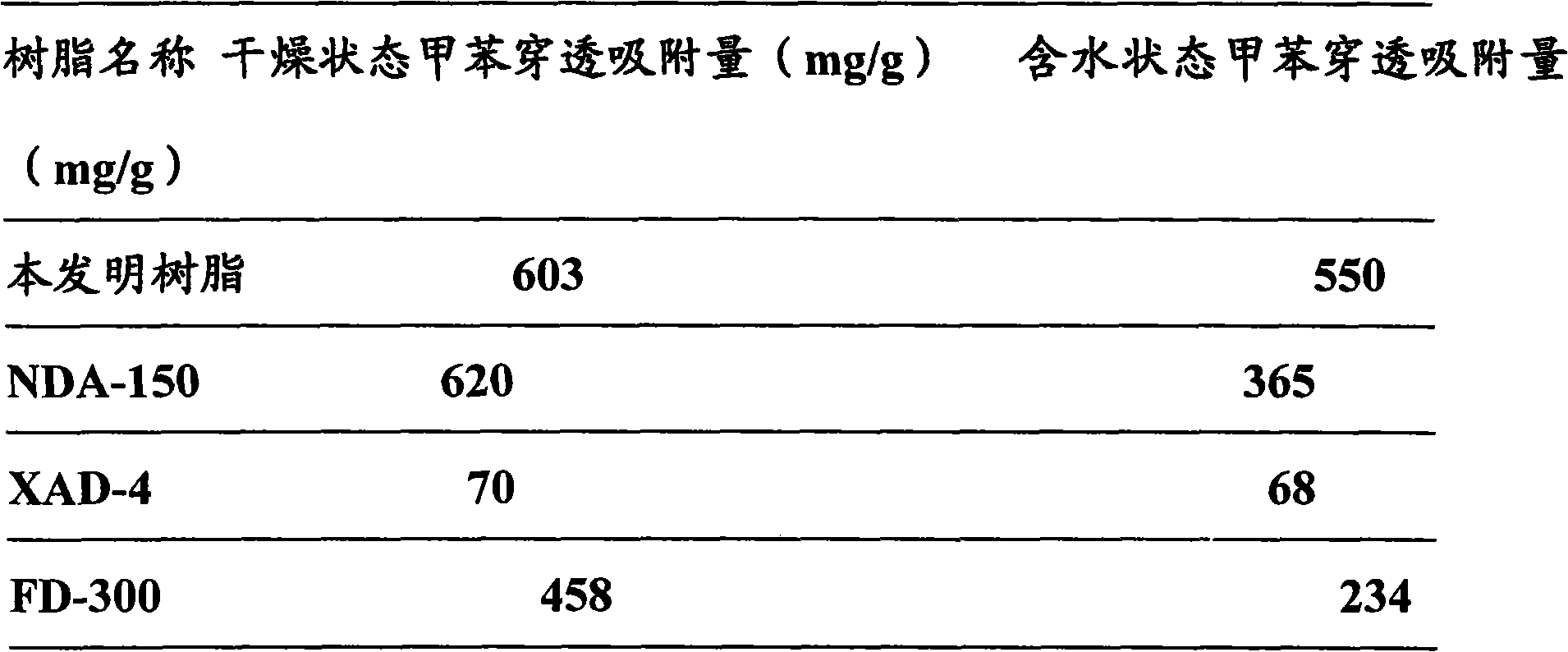

Hydrophobic high-micropore polymeric adsorbent, preparation and uses thereof

A technology of adsorption resin and hydrophobicity, which is applied in the field of adsorption resin and its synthesis, can solve the problems such as the difficult drying of resin and the limitation of the application of ultra-high cross-linking adsorption resin, and achieve the effect of simple reagent, simple equipment and easy regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1. Preparation of hydrophobic high microporous adsorption resin

[0037] A Suspension Polymerization: The synthesis of low-crosslinked linear polymers adopts the suspension polymerization method. In the water phase (500g), 3g of gelatin should be added as a dispersant, 7g of sodium carbonate and 23g of magnesium sulfate should be added. The oil phase (150 g) comprises: 52.5 g of styrene, 40 g of p-methylstyrene, 7.5 g of divinylbenzene (80% purity), 50 g of toluene, and 3 g of initiator benzoyl peroxide. Both the oil phase and the aqueous phase were pre-gassed with nitrogen for 5 minutes to remove oxygen in the solution before use. The polymerization reaction is carried out in a 1000 ml three-necked flask. The water phase is stirred for a period of time under the condition of nitrogen gas, and then the oil phase is added. The speed of the stirrer is controlled at 300 rpm, and the polymerization reaction temperature is 78 ° C. After 10 hours of reaction Then...

Embodiment 2

[0040] Embodiment 2. Preparation of hydrophobic high microporous adsorption resin

[0041] The specific operation steps are the same as in Example 1, except that the aqueous phase (500g) in step A: add 1g of hydroxycellulose as a dispersant, add 3g of sodium carbonate, and 30g of magnesium sulfate. Oil phase (150g): contains monomer styrene 55g, 4-tert-butylstyrene 40g, divinylbenzene (purity 80%) 5g, toluene 50g, add initiator benzoyl peroxide 1g, azobisisobutyl Nitrile 2g. Product B is obtained.

Embodiment 3

[0043] The specific operation steps are the same as in Example 1, except for the aqueous phase (500g) in step A: add 3g of gelatin as a dispersant, add 3g of sodium carbonate, and 30g of magnesium sulfate. Oil phase (150g): Contains 57.5g of monomer styrene, 40g of 4-isobutylstyrene, 2.5g of divinylbenzene (80% purity), 50g of No. 200 mineral spirits, and 3g of initiator benzoyl peroxide. Product C is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com