Catalytic conversion method for biological oil and fat

A catalytic conversion method and bio-oil technology, which are applied in the field of catalytic conversion of bio-oil, can solve problems such as unreported olefin yield, and achieve the effects of sustainable economic development, high low-carbon olefin yield, and promotion of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

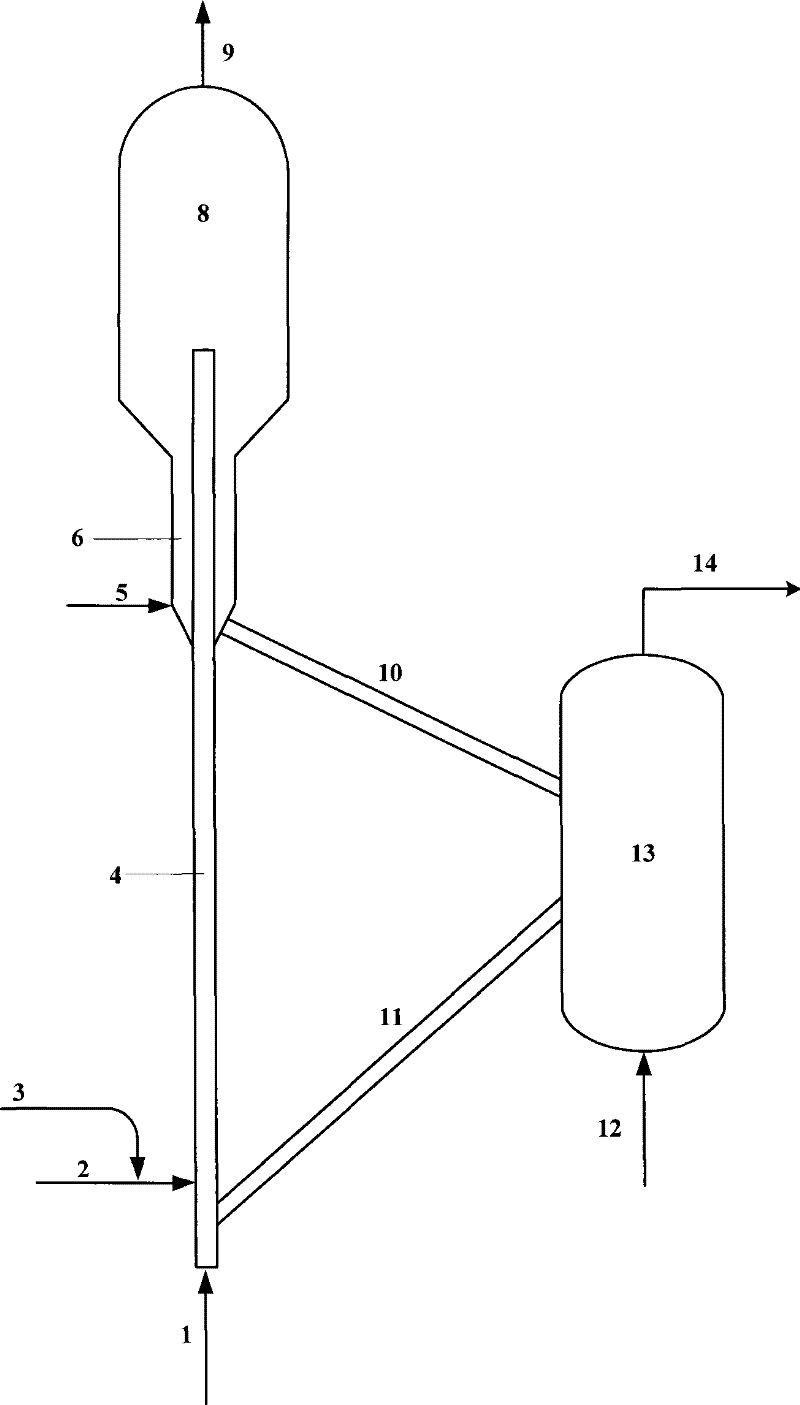

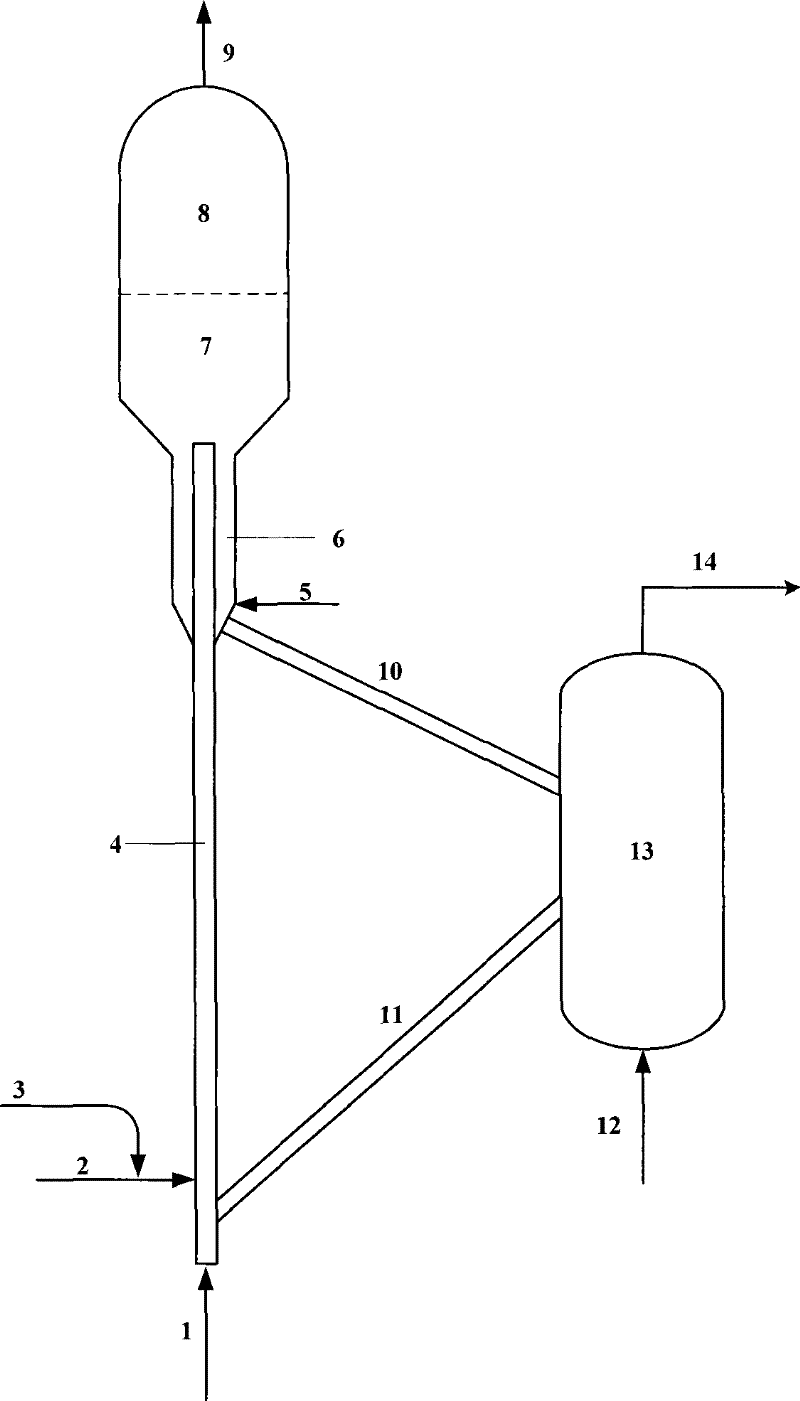

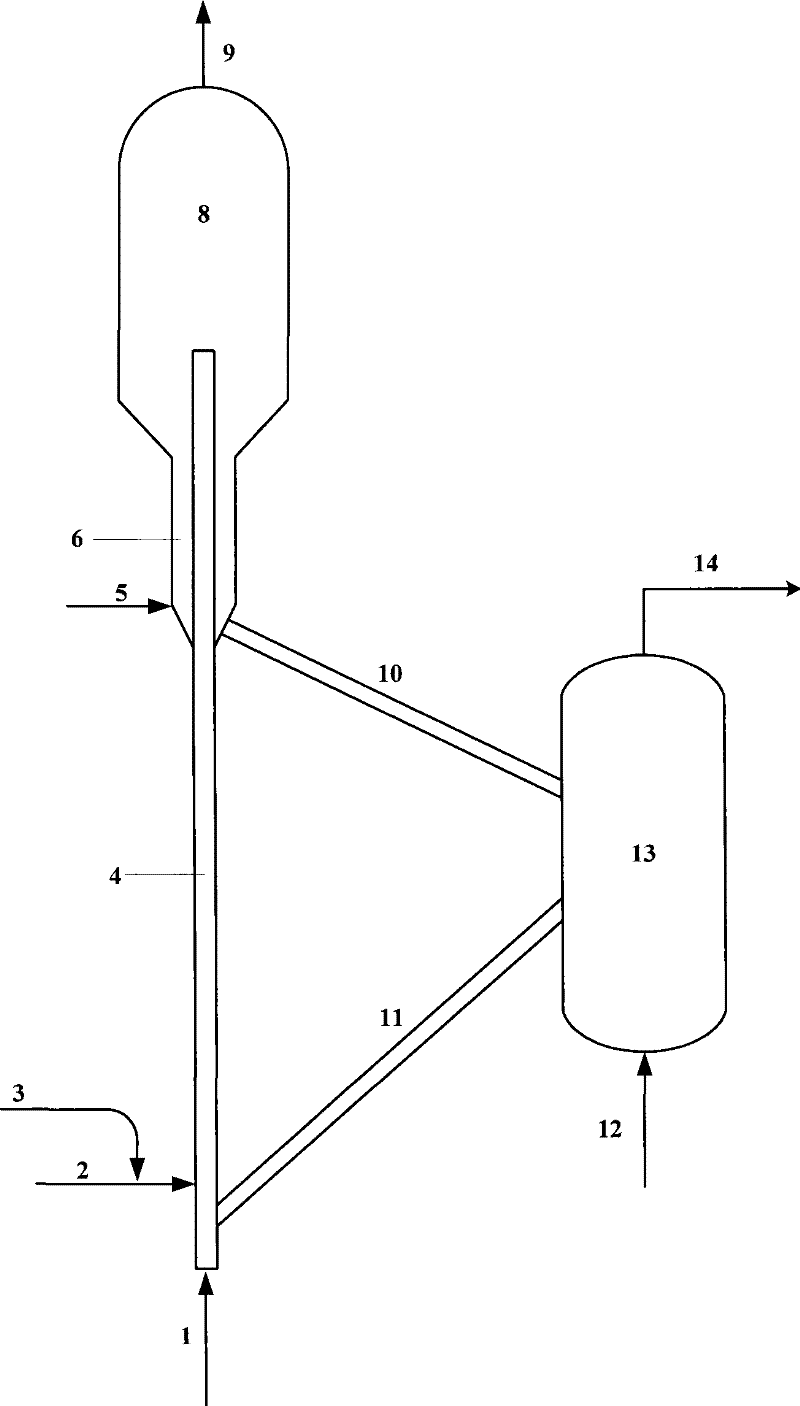

[0031] This example illustrates: adopting the method provided by the present invention, the result of the catalytic conversion of bio-oil in the riser reactor.

[0032] The composition of the catalyst used in Example 1 is as follows: based on the total weight of the catalyst, the content of the zeolite with the MFI structure and the modified beta zeolite are respectively 20% by weight, 10% by weight, and 20% by weight al 2 o 3 , 50% kaolin by weight. Among them, β zeolite is modified by phosphorus and Zn (P 2 o 5 and ZnO weight content were 1.5% and 1.6%).

[0033] The experiments were carried out on a medium-sized riser setup for continuous reaction-regeneration operation with an internal diameter of 16 mm and a height of 6 m.

[0034] The bio-oil raw material used in this example is palm oil, and the experiment adopts a single-pass operation mode. The regenerated catalyst with a temperature of about 700°C enters the bottom of the reaction section of the riser through t...

Embodiment 2

[0043] This example illustrates: adopting the method provided by the present invention, the catalytic conversion result of bio-oil in riser+fluidized bed reactor.

[0044] The composition of the catalyst used in Example 2 is as follows: based on the total weight of the catalyst, the content of the zeolite with MFI structure and the modified beta zeolite are respectively 10% by weight, 20% by weight, and 20% by weight Al 2 o 3 , 50% kaolin by weight. Among them, β zeolite is modified by phosphorus and Fe (P 2 o 5 and Fe 2 o 3 The weight content is respectively 2.0% and 1.8%).

[0045] The experiment was carried out on a medium-sized riser + fluidized bed unit with continuous reaction-regeneration operation. Wherein the inner diameter of the riser is 16 millimeters, and the height is 6 meters. Above the outlet of the riser is a fluidized bed, and the inner diameter of the fluidized bed is 64 millimeters, and the height is 0.3 meters.

[0046] The bio-oil raw material use...

Embodiment 3

[0049] This example illustrates: adopting the method provided by the present invention, the result of the catalytic conversion of bio-oil in the riser reactor.

[0050] The composition of the catalyst used in Example 3 is as follows: based on the total weight of the catalyst, the content of the zeolite with MFI structure and the modified beta zeolite are respectively 20% by weight, 10% by weight, and 20% by weight al 2 o 3 , 50% kaolin by weight. Among them, β zeolite was modified by phosphorus and Cu (P 2 o 5 and CuO weight content were 1.5% and 1.5%).

[0051] The bio-oil raw material used in this example is lard. The reaction device and main experimental steps used in the experiment are the same as those in Example 1. The main operating conditions and results are listed in Table 3.

[0052] As can be seen from Table 3, in the method of the present invention, the total yield of the C4 product with a boiling point of less than or equal to 55.78% by weight; wherein the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com