High-efficiency dephosphorization smelting method for medium phosphor hot metal revolving furnace

A smelting method and molten iron technology, applied in the manufacture of converters, etc., can solve the problems of slow smelting rhythm, high smelting cost, environmental pollution, etc., and achieve the effect of speeding up the smelting rhythm and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

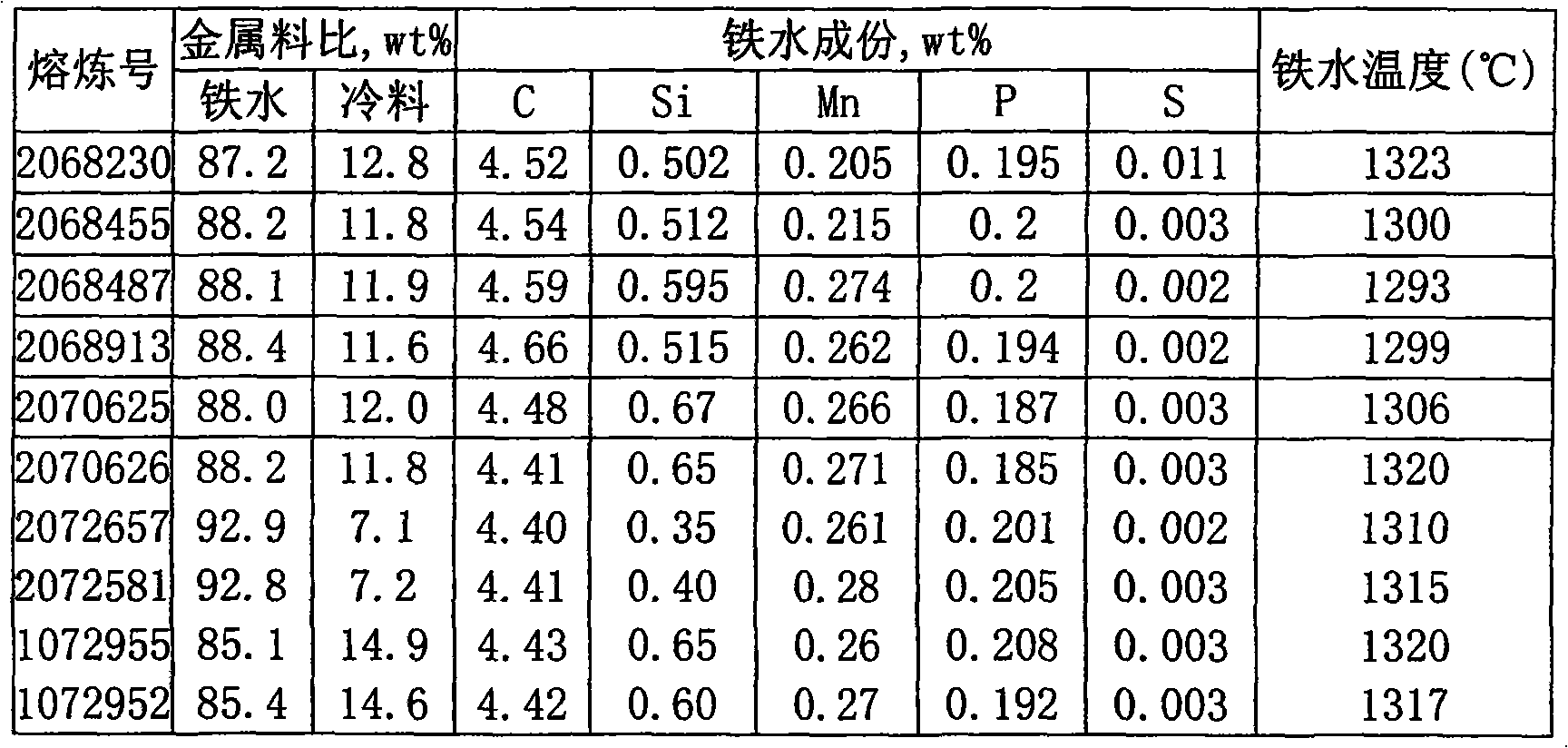

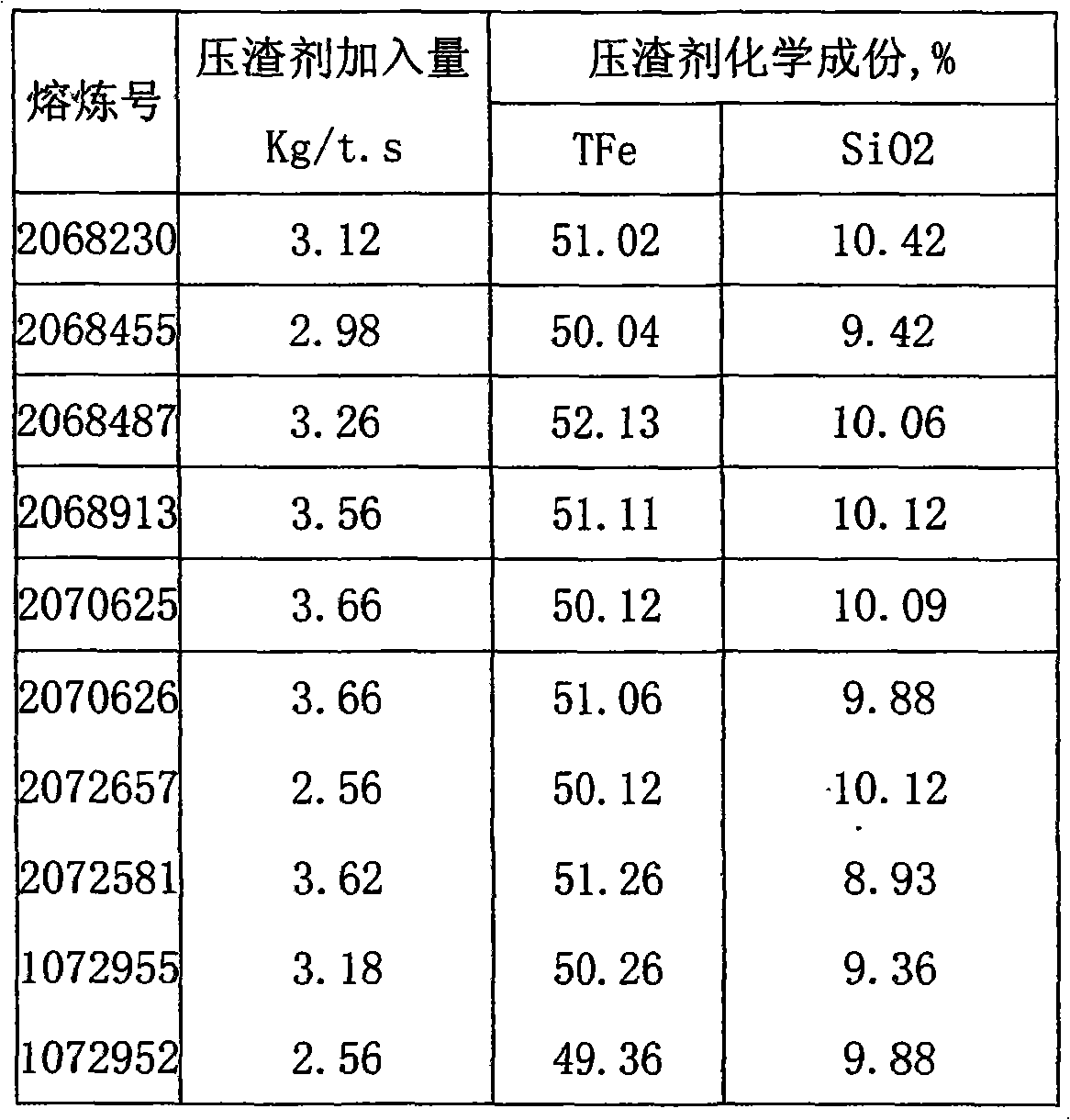

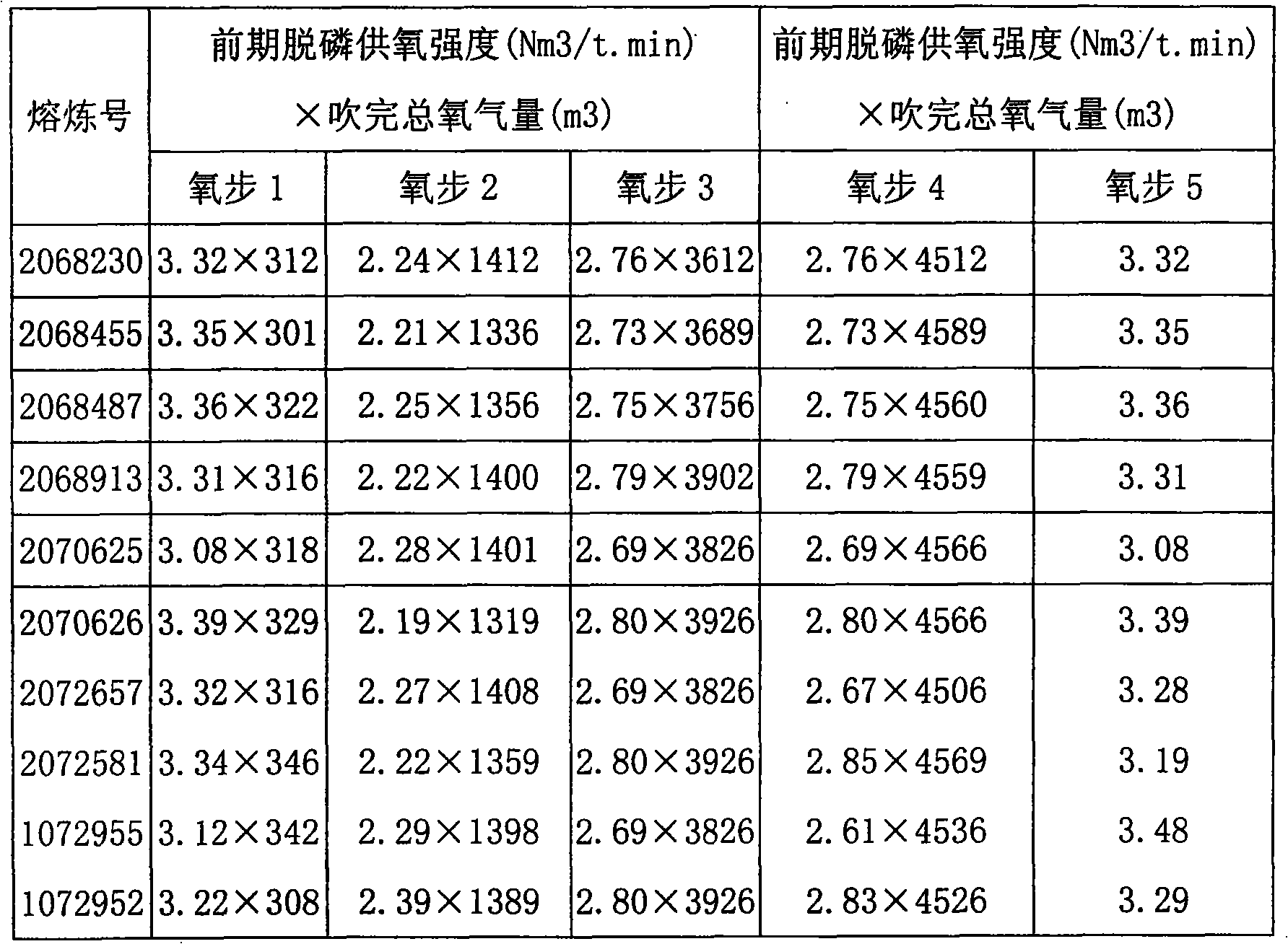

[0014] According to the invented low-phosphorus method for smelting medium-phosphorus molten iron in a converter, 10 furnaces were smelted on a 150-ton converter, and the main metal materials were molten iron, scrap steel and pig iron (with the same phosphorus content as molten iron). See Table 1 for the ratio of metal materials and the phosphorus content of molten iron. In the early stage of converter smelting, dephosphorization treatment is carried out, and quicklime and ore are added. Add the slag pressing agent after the dephosphorization in the early stage, and see Table 2 for the specific composition and dosage. After pouring slag, add lime and ore to adjust slag according to the slag formation. The oxygen supply intensity of the whole process is shown in Table 3. The chemical composition of the end point obtained from smelting is shown in Table 4.

[0015] Table 1. Implementation of main raw material ratio and molten iron parameters

[0016]

[0017] Table 2. Imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com