Quick test method for metakaolin activity used for inorganic polymer gelled material

An inorganic polymer, metakaolin technology, applied in the direction of chemical reaction of materials, material analysis by observing the effect on chemical indicators, etc. Metakaolin activity and other issues, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

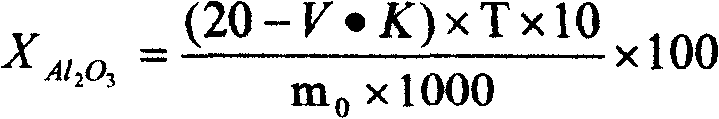

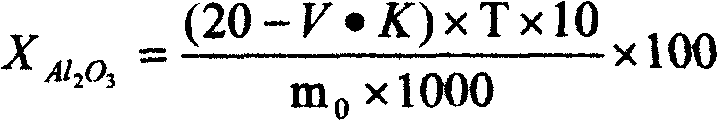

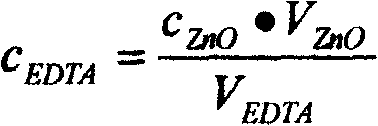

Embodiment 1

[0049] Kaolin is calcined in an experimental electric furnace with a heating rate of 10°C / min, kept at 800°C for 2 hours, and cooled to about 60°C to take out the material. Weigh 0.5002 g of the calcined metakaolin sample, pour it into 20 mL of standard hydrochloric acid with a mass percent concentration of 20% heated to 80° C. in a constant temperature water bath, and stir for 2 hours. Filter, pour the filtrate into a 200mL volumetric flask, and dilute to the mark at 200mL. Use a pipette to pipette 20 mL of the filtrate into a 300 mL jar, add 20 mL of acetic acid-ammonium acetate buffer solution to adjust the pH of the solution to 3, add 20 mL of 0.035 mol / L EDTA standard titration solution, and dilute to 100 mL with distilled water. Cover the bottle with a watch glass and boil for 2 minutes, then cool to room temperature. Add 2 mL of nitroso red salt as indicator, and titrate with 0.035 mol / L copper sulfate standard titration solution, the indicator changes from yellow to e...

Embodiment 2

[0064] Kaolin is calcined in an experimental electric furnace with a heating rate of 10°C / min, kept at 700°C for 2 hours, and cooled to about 60°C to take out the material. Weigh 0.5000 g of the calcined metakaolin sample, pour it into 20 mL of standard hydrochloric acid with a mass percent concentration of 20% heated to 80° C. in a constant temperature water bath, and stir for 2 hours. Filter, pour the filtrate into a 200mL volumetric flask, and dilute to the mark. Use a pipette to pipette 20 mL of the filtrate into a 300 mL jar, add 20 mL of acetic acid-ammonium acetate buffer solution to adjust the pH of the solution to 4.5, add 0.035 mol / L EDTA standard titration solution 20 mL, and dilute to 100 mL with distilled water. Cover the bottle with a watch glass and boil for 3 minutes, then cool to room temperature. Add 2.5 mL of nitroso red salt as indicator, and titrate with 0.035 mol / L copper sulfate standard titration solution, the indicator changes from yellow to emerald g...

Embodiment 3

[0068] The kaolin was calcined in an experimental electric furnace with a heating rate of 10°C / min, kept at 600°C for 2 hours, and cooled to about 60°C to take out the material. Weigh 0.5000 g of the calcined metakaolin sample, pour it into 20 mL of standard hydrochloric acid with a mass percent concentration of 20% heated to 80° C. in a constant temperature water bath, and stir for 2 hours. Filter, pour the filtrate into a 200mL volumetric flask, and dilute to the mark. Use a pipette to pipette 20 mL of the filtrate into a 300 mL jar, add 20 mL of acetic acid-ammonium acetate buffer solution to adjust the pH of the solution to 4.5, add 0.035 mol / L EDTA standard titration solution 20 mL, and dilute to 100 mL with distilled water. Cover the bottle with a watch glass and boil for 3 minutes, then cool to room temperature. Add 3 mL of nitroso red salt as indicator, and titrate with 0.035 mol / L copper sulfate standard titration solution, the indicator changes from yellow to emeral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com