Reverse osmosis treatent method and device for carbonized wastewater

A technology for coking wastewater and treatment equipment, which is applied in the fields of metallurgical wastewater treatment, permeation/dialysis water/sewage treatment, chemical instruments and methods, etc. The effect of small size and high degree of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

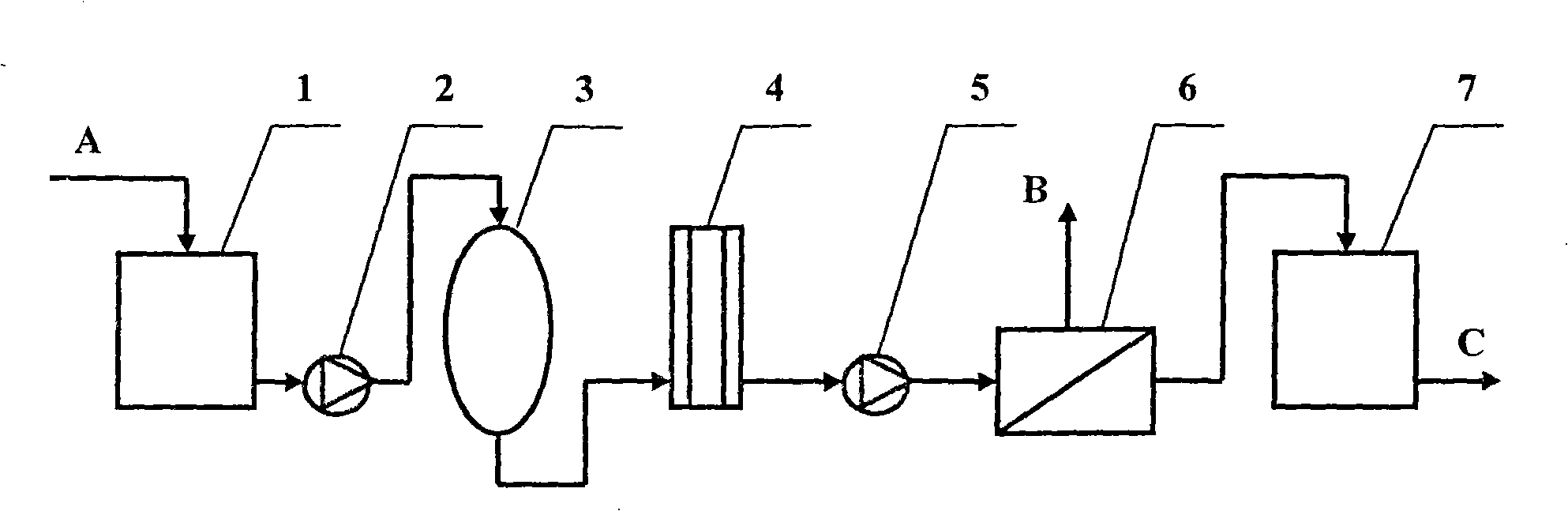

[0019] Complete a pilot plant of reverse osmosis treatment of coking wastewater, and install all the equipment in a 20-foot container. The design parameters of the equipment are: water inlet tank 500L, raw water pump 1m 3 / h, 3kg / cm 2 , multi-media filter Φ200mm, security filter Φ4″X20″PE melt-blown filter element 1, high-pressure water pump 1m 3 / h、60kg / cm 2 , reverse osmosis adopts Φ254X1110mm, 9m 2 One flat sewage treatment type reverse osmosis membrane, reverse osmosis production water tank 500L. In addition, the supporting reverse osmosis backwashing and cleaning water pump and the multi-media filter backwashing share one water pump, which is 2m 3 / h, 3kg / cm 2 , chemical online cleaning PE dosing box 100L2, dosing metering pump 0~14L / h, 7kg / cm 2 2 units.

[0020] The influent water volume is 900L / h, the reverse osmosis product water volume is 700L / h, and the reverse osmosis concentrate water volume is 200L / h.

[0021] Coking wastewater quality: COD 5504mg / L, NH 3...

Embodiment 2

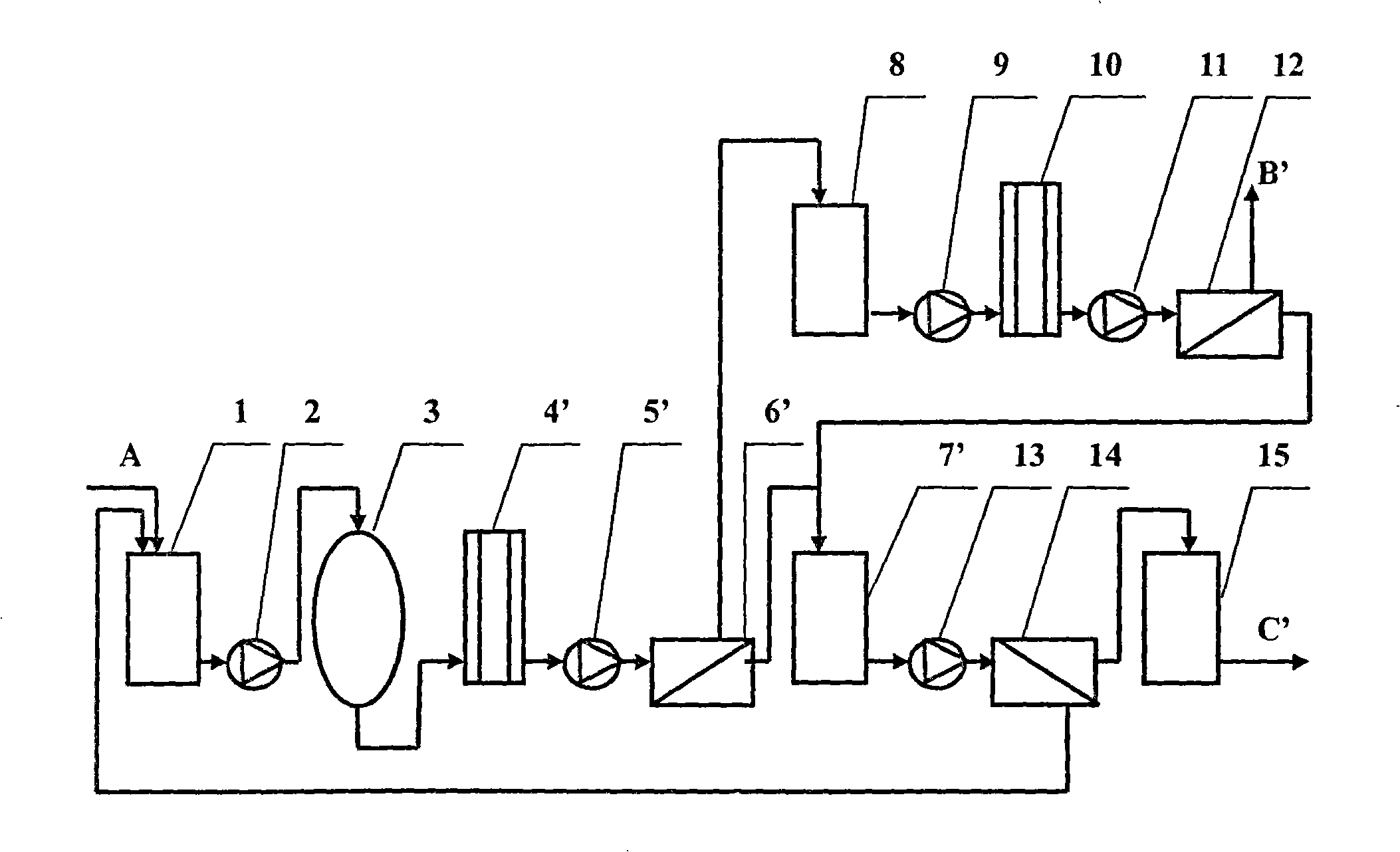

[0024] Design a combined enhanced reverse osmosis system for coking wastewater. The design parameters of the system equipment are: (1) One-stage reverse osmosis system: water inlet tank 30m 3 , raw water pump 66.5m 3 / h, 3kg / cm 2 , multi-media filter Φ1600mm, a section of security filter Φ4″X40″PE melt-blown filter element 34 pieces, a section of high-pressure water pump 66.5m 3 / h、63kg / cm 2 , one stage of reverse osmosis adopts Φ254X1110mm, 9m 2 81 flat sewage treatment reverse osmosis membranes, 85% water production rate of the first stage of reverse osmosis, 30m reverse osmosis water production tank 3 , a section of reverse osmosis concentrated water tank 10m 3 , matching multi-media filter backwash pump 180m 3 / h, 3kg / cm 2 , a section of reverse osmosis backwash and cleaning water pump 100m 3 / h, 3kg / cm 2 , chemical on-line cleaning PE dosing box 2000L 2, dosing metering pump 0~150L / h, 7kg / cm 2 2 sets; (2) Two-stage reverse osmosis system: middle pump 10m 3 / h, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com