Process for manufacturing barium zirconium titanate ceramic

A ceramic material, the technology of barium zirconate titanate, applied in the field of preparing barium zirconate titanate ceramic material, can solve the problems that the method of barium zirconate titanate ceramic material has not been introduced, it is not suitable for large-scale production and application, and the price of rare earth raw materials is expensive. Achieve the effect of good shape and dielectric properties, strong dielectric nonlinearity, and not easy to fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

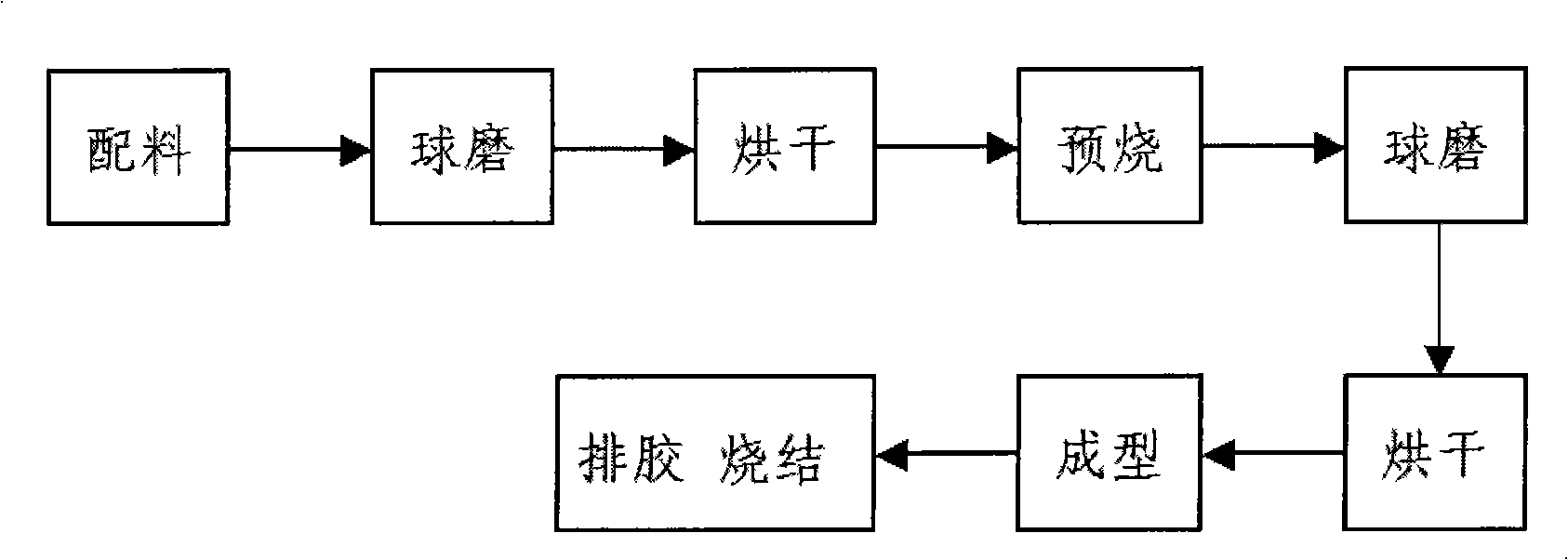

[0040] see figure 1 , to prepare BaZr 0.2 Ti 0.8 o 3 The barium zirconate titanate ceramic material comprises the steps:

[0041] (1) Ingredients

[0042] Using electronic balance to weigh high-purity BaCO 3 34.5121 grams, ZrO 2 4.3115 grams, TiO 2 11.1787 grams;

[0043] (2) ball mill

[0044] Pour the powder into a ball mill jar, add 65 grams of zirconia balls and 80 ml of deionized water, and perform planetary ball milling at 500 rpm for 2 hours; it should be noted that since the zirconia balls are spherical, they cannot be accurately weighed. It is also difficult to accurately weigh deionized water, so in the examples, deionized water and zirconia balls are weighed in integers.

[0045] (3) drying

[0046] The slurry after ball milling is poured into a porcelain dish, placed in an oven and baked at 80°C for 24 hours;

[0047] (4) pre-burning

[0048] Pour the dried powder into an agate mortar and grind it for 3 minutes, then place it in a resistance furnace, an...

Embodiment 2

[0058] see figure 1 , to prepare BaZr 0.5 Ti 0.5 o 3 The barium zirconate titanate ceramic material comprises the steps:

[0059] (1) Ingredients

[0060] Using electronic balance to weigh high-purity BaCO 3 39.462 g, ZrO 2 6.161 g, TiO 2 3.991 grams;

[0061] (2) ball mill

[0062] Pour the powder into a ball mill jar, add 60 grams of zirconia balls and 100 ml of deionized water, and grind the planetary ball for 0.5 hours at 1000 rpm;

[0063] (3) drying

[0064] The slurry after ball milling is poured into a porcelain dish, placed in an oven and baked at 100°C for 24 hours;

[0065] (4) pre-burning

[0066] Pour the dried powder into an agate mortar and grind it for 3 minutes, then place it in a resistance furnace, and use an intelligent temperature regulator to control the temperature rise and fall program of the resistance furnace, so that the temperature in the furnace will rise from room temperature to 1150°C at a constant speed within 300 minutes Finally, ke...

Embodiment 3

[0076] see figure 1 , to prepare BaZr 0.05 Ti 0.95 o 3 The barium zirconate titanate ceramic material comprises the steps:

[0077] (1) Ingredients

[0078] Using electronic balance to weigh high-purity BaCO 3 39.6603 grams, ZrO 2 1.2384 g, TiO 2 15.2535 grams;

[0079] (2) ball mill

[0080] Pour the powder into a ball mill jar, add 90 grams of zirconia balls and 112ml of deionized water, and grind the planetary ball for 10 hours at a speed of 100 rpm;

[0081] (3) drying

[0082] The slurry after ball milling is poured into a porcelain dish, placed in an oven and baked at 90°C for 24 hours;

[0083] (4) pre-burning

[0084] Pour the dried powder into an agate mortar and grind it for 3 minutes, then place it in a resistance furnace, and use an intelligent temperature regulator to control the temperature rise and fall program of the resistance furnace, so that the temperature in the furnace will rise from room temperature to 1250°C at a constant speed within 300 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com