Production method for type II CdTe/CdS quantum point

A technology of core-shell quantum dots and stock solution, which is applied in the field of preparation of fluorescent nanomaterials, can solve problems such as unfavorable photoelectric device applications, and achieve the effects of low price, safe raw materials, and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

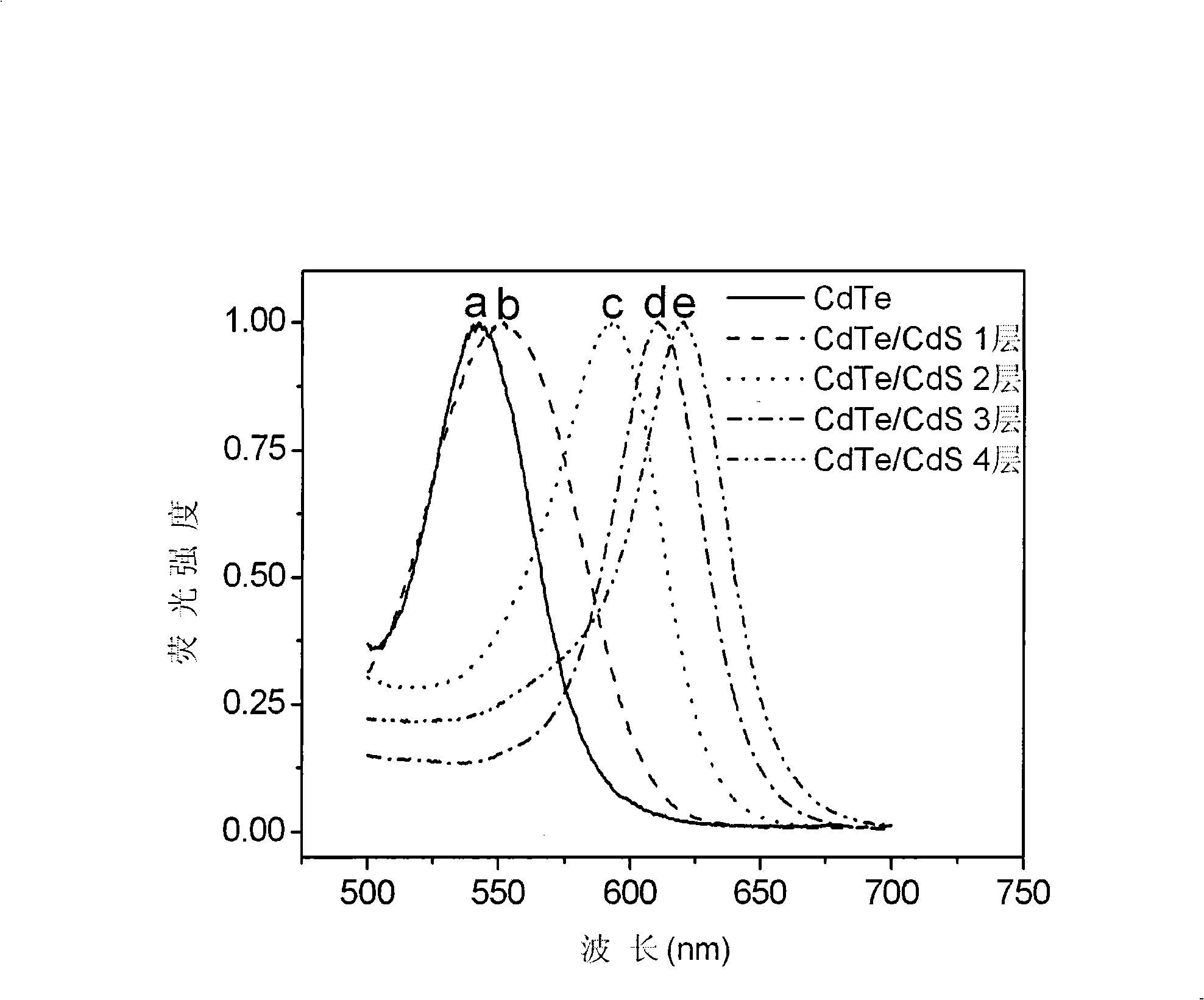

Image

Examples

Embodiment 1

[0016] Type II CdTe / CdS core-shell quantum dots were prepared as follows:

[0017] 1. Weigh 0.0256g of CdO powder, 0.228g of stearic acid, and 2ml of octadecene, and put them into a three-necked bottle. The molar ratio of CdO to stearic acid is 1:4, and the molar concentration of Cd is 0.1mol / l. Fill with argon gas while magnetically stirring, heat to 200°C with a heating mantle, keep for 3 minutes until the solution is colorless and transparent, then cool down naturally to 50°C to prepare a cadmium precursor solution.

[0018] 2. Weigh 0.0128g of tellurium powder and put it into a penicillin bottle, add 2ml of tri-n-octylphosphine and 2ml of octadecene, the molar ratio of tellurium powder to tri-n-octylphosphine is 1:45, and the molar concentration of tellurium powder is 25mmol / l. After sealing, ultrasonication was performed for about 30 minutes to completely dissolve the tellurium powder to obtain a tellurium precursor solution.

[0019] 3. Add 3 g of hexadecylamine and ...

Embodiment 2

[0024] Type II CdTe / CdS core-shell quantum dots were prepared as follows:

[0025] 1. Weigh 0.0256g of CdO powder, 0.228g of stearic acid, and 2ml of octadecene, and put them into a three-necked bottle. The molar ratio of CdO to stearic acid is 1:4, and the molar concentration of Cd is 0.1mol / l. Fill with argon gas while magnetically stirring, heat to 200°C with a heating mantle, keep for 3 minutes until the solution is colorless and transparent, then cool down naturally to 50°C to prepare a cadmium precursor solution.

[0026] 2. Weigh 0.0128g of tellurium powder and put it into a penicillin bottle, add 2ml of tri-n-octylphosphine and 2ml of octadecene, the molar ratio of tellurium powder to tri-n-octylphosphine is 1:45, and the molar concentration of tellurium powder is 25mmol / l. After sealing, ultrasonication was performed for about 30 minutes to completely dissolve the tellurium powder to obtain a tellurium precursor solution.

[0027] 3. Add 3 g of hexadecylamine and ...

Embodiment 3

[0032] Type II CdTe / CdS core-shell quantum dots were prepared as follows:

[0033] 1. Weigh 0.0256g of CdO powder, 0.228g of stearic acid, and 2ml of octadecene, and put them into a three-necked bottle. The molar ratio of CdO to stearic acid is 1:4, and the molar concentration of Cd is 0.1mol / l. Fill with argon gas while magnetically stirring, heat to 200°C with a heating mantle, keep for 3 minutes until the solution is colorless and transparent, then cool down naturally to 50°C to prepare a cadmium precursor solution.

[0034]2. Weigh 0.0128g of tellurium powder and put it into a penicillin bottle, add 2ml of tri-n-octylphosphine and 2ml of octadecene, the molar ratio of tellurium powder to tri-n-octylphosphine is 1:45, and the molar concentration of tellurium powder is 25mmol / l. After sealing, ultrasonication was performed for about 30 minutes to completely dissolve the tellurium powder to obtain a tellurium precursor solution.

[0035] 3. Add 3 g of hexadecylamine and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com