Method for realizing low carbon-nitrogen rate high concentration nitrogen-containing waste water steady biological hitrosation

A low-carbon-to-nitrogen ratio, high-concentration technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve problems such as system collapse, low sludge growth, and sludge loss, and achieve Effects of maintaining uniformity, avoiding FA inhibition, and buffering influent load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

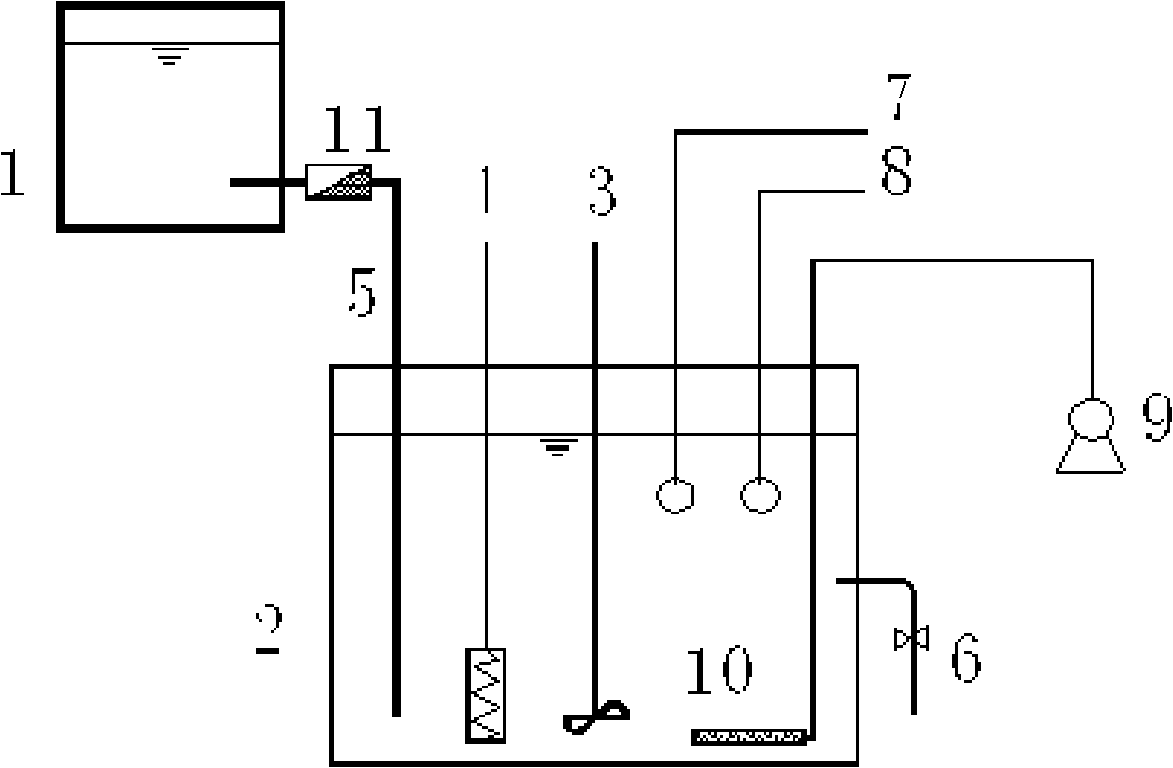

Image

Examples

Embodiment 1

[0030] Example 1: The treated wastewater is artificial water distribution to simulate landfill leachate, and the test water distribution fully considers the complexity of water quality, except for COD and NH 4 + In addition to -N, add appropriate phosphorus, alkalinity, trace elements, etc. Make an organic plastic cylindrical SBR reactor with an effective volume of 20 liters (L). The water pipes are distributed at multiple points at 10cm from the bottom of the pool. After a 12-hour reaction cycle (continuous water intake for 12 hours, continuous aeration for 1.5 hours, static sedimentation for 20 minutes, and intermittent drainage for 10 minutes), 10 L is discharged from the drain pipe. Drain the mixed solution 5 minutes before the end of the gas stage to control the sludge age. Specific steps are as follows:

[0031] 1. Sludge inoculation and cultivation stage: The inoculation sludge is activated sludge from the aeration tank of the urban sewage treatment plant. The syste...

Embodiment 2

[0034] Example 2: Using the actual late-stage landfill leachate as the influent, according to the operating mode of Example 1, keeping the system operating mode and various operating parameters unchanged, the system was stable and operated continuously for 126 days. as follows

[0035] COD

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com