Method for preparing polymer nanometer optical waveguide coupling beam divider

A production method and polymer technology, applied in the field of nanophotonics, can solve the problems of high cost, large size of the coupling part, complicated production method, etc., and achieve the effects of low cost, small optical loss, and good spectroscopic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

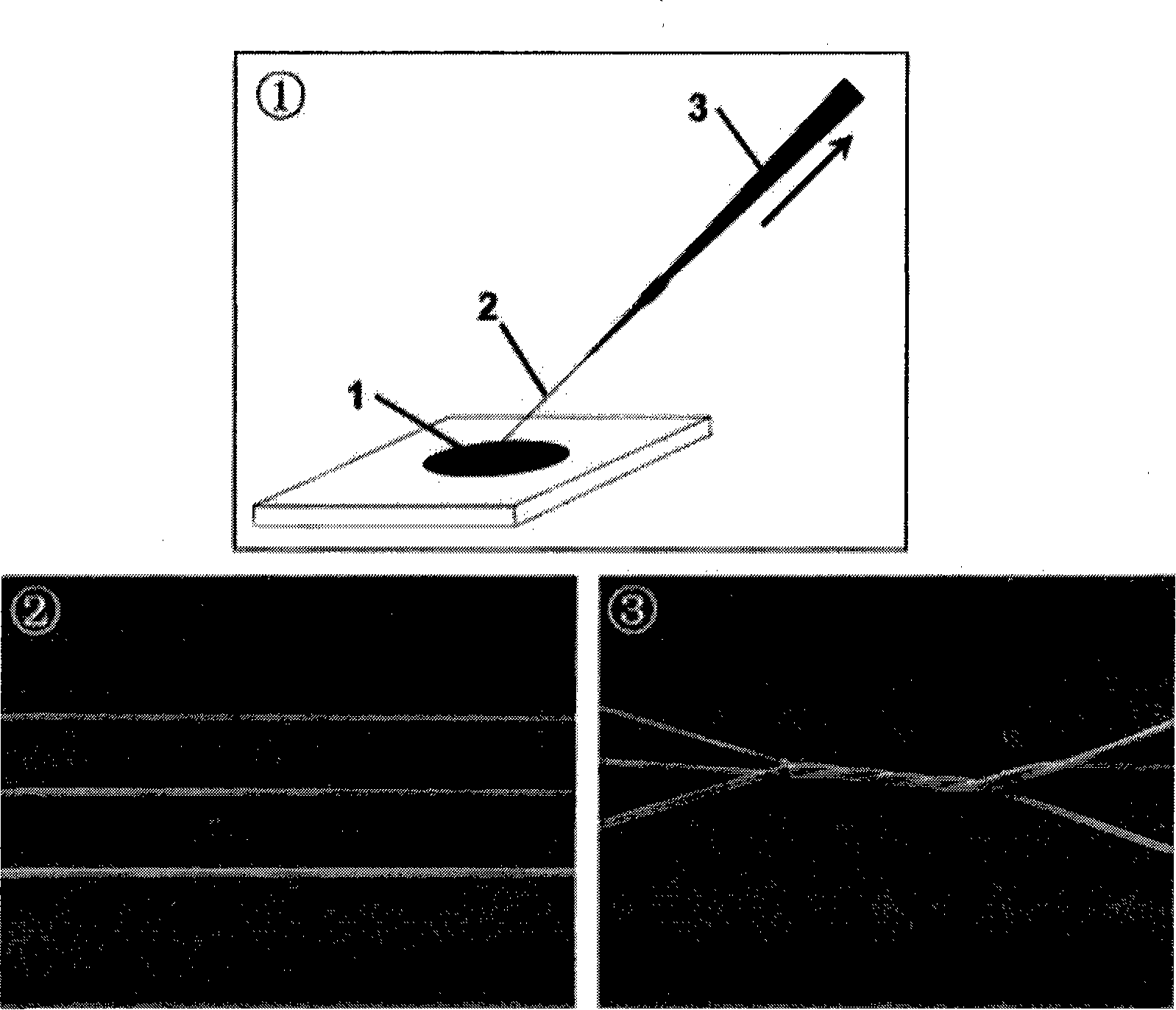

Method used

Image

Examples

Embodiment 1

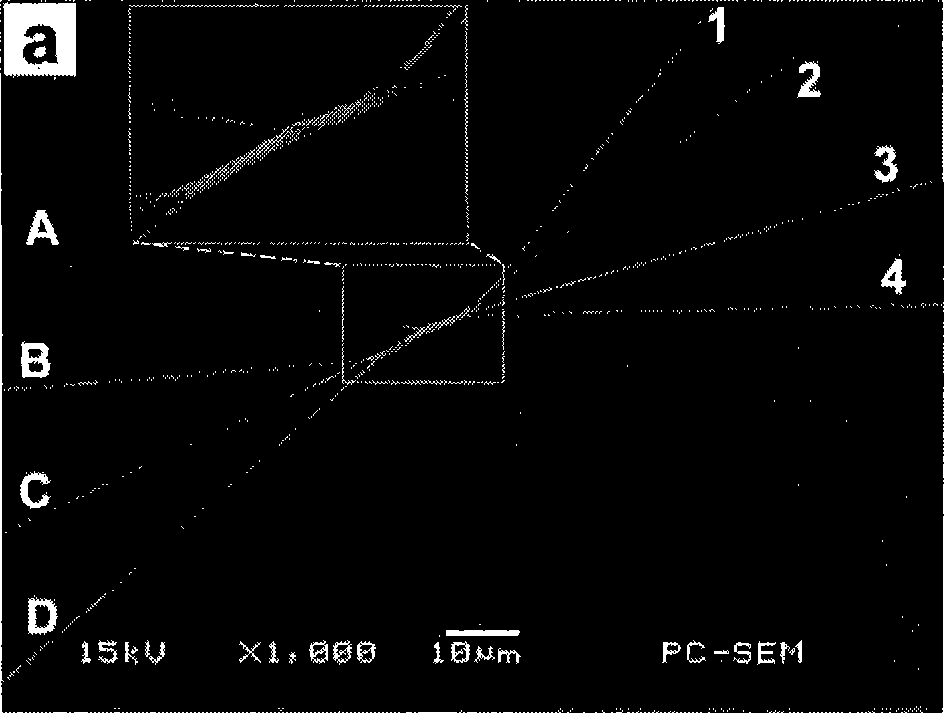

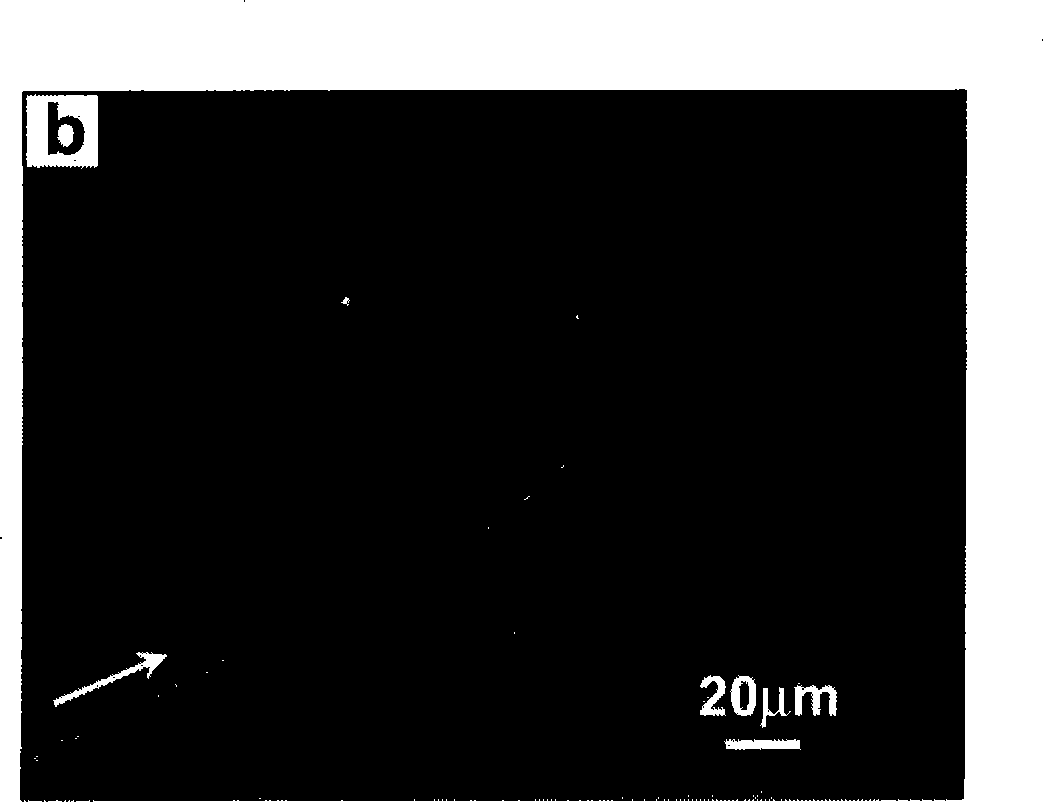

[0038] Four PTT nano-optical waveguides were wound and assembled to form a 4×4 optical power beam splitter using micro-operation winding technology, in which the diameters of the nano-optical waveguides from branch A to branch D were 450, 450, 510 and 570 nm, respectively. Figure 2(a) is the SEM image of the device. It can be seen from the inset that the device is composed of a 3×4 and 1×4 coupler cascaded, and the total width of the coupling part is 1.98 μm. The maximum length of the coupling part of the device is about 16.1 μm, and the coupling length of the 1×4 beam splitter is about 8.5 μm. The optical signal is coupled into the device by means of evanescent wave coupling, and then the optical splitting performance of the device is tested. Here the average value of the input and output total loss is 0.480dB. As shown in Figure 2(b), when the red light with a working wavelength of 650nm is coupled into branch B, it is divided into four parts and output from branches 1 to 4...

Embodiment 2

[0040] Figure 3 shows a 6×6 polymer nano-optical waveguide coupled beam splitter assembled by winding six PTT nano-optical waveguides. The diameters of the PTT fibers of branches A-F are 520, 540, 540, 540, 420, and 360 nm, respectively. The inset of Fig. 3(a) presents a magnified image of the winding part, where the coupling part has a length of 11–20 μm and a width of 2.92 μm. As shown in Figure 3(b), when the green light with a wavelength of 532nm is coupled into branch C, the coupled part is divided into six parts and output in branches 1-6, and the splitting ratio is 17:16:20:18:15: 14. In this case, the splitting uniformity of the beam splitter is 1.55dB. When blue light with a wavelength of 650nm is input into branch D, the power distribution of the six output branches of the beam splitter is very uniform, and the uniformity of light splitting is only 0.03dB ( Figure 3c ). Visible light of different wavelengths is also coupled into branches C and D, respectively, to d...

Embodiment 3

[0042] Figure 4 shows an 8×8 polymer nano-optical waveguide coupling beam splitter with a long coupling part, which is composed of 8 diameters of 400, 400, 400, 400, 400, 750, 750 and 600nm (branches A-H) The PTT nano-optical waveguide is assembled. As shown in the SEM image in the inset of Fig. 4(a), the length and width of the coupling part are approximately 38 μm and 2.5 μm. We coupled three kinds of visible light into 8×8 beam splitting to observe the splitting performance of the device. As shown in Figure 4(b), (c), red light and blue light are coupled into branches E and G respectively, and are divided into branches 1-8 for output through the coupling part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com