Device for purifying and treating tail gas

A treatment device and exhaust gas purification technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of complex process technology, large wind resistance of absorption towers, and high maintenance costs, and achieve simple technical structure and wide application. , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

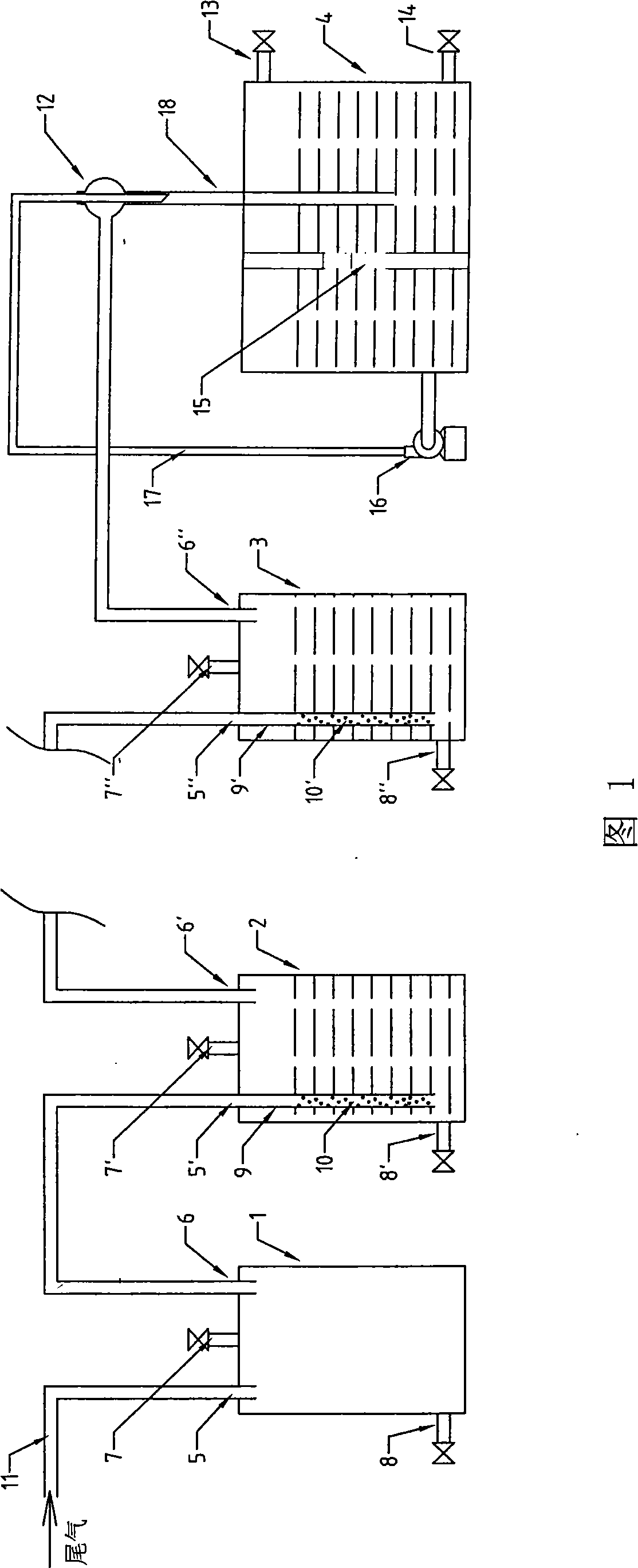

[0010] The following is an explanatory description of an embodiment of the present invention with reference to the accompanying drawing 1, but it must be understood that this embodiment cannot be construed as limiting the present invention.

[0011] This embodiment is: a tail gas purification treatment device, including tail gas buffer tank 1, tail gas alkali absorption tank 2, tail gas alkali absorption tank 3, and waste water circulation pool 4 arranged in sequence; the tank body upper end of the above tail gas buffer tank 1 is provided Air inlet 5, air outlet 6 and venting port 7 are arranged, and liquid outlet 8 is arranged on the lower side of the tank body; the tank body top of the above-mentioned tail gas alkali absorption tank 2 is also provided with air inlet 5', air outlet 6' and venting port Port 7 ', the tank body lower side also has a liquid discharge port 8 ', and the tank body top of the tail gas alkali absorption tank 3 is also provided with an air inlet 5 ", an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com