Anaerobic oxygen rubber composition

A composition, anaerobic adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of strong, toxicity, etc., achieve the effect of low odor, low volatility, and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

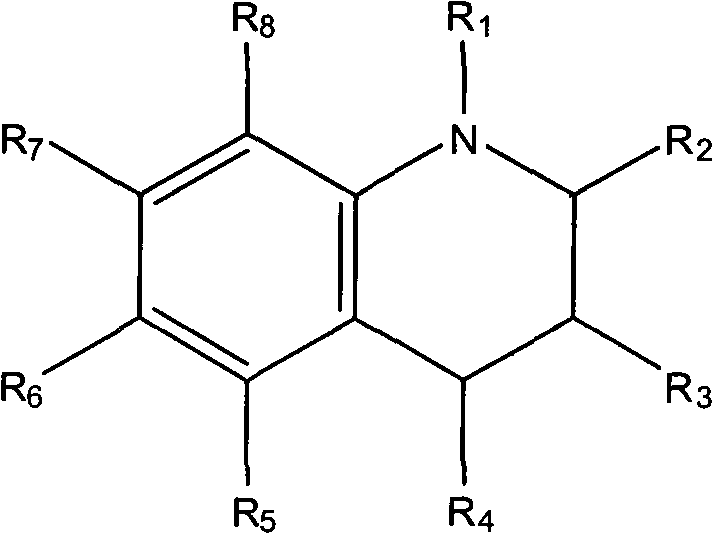

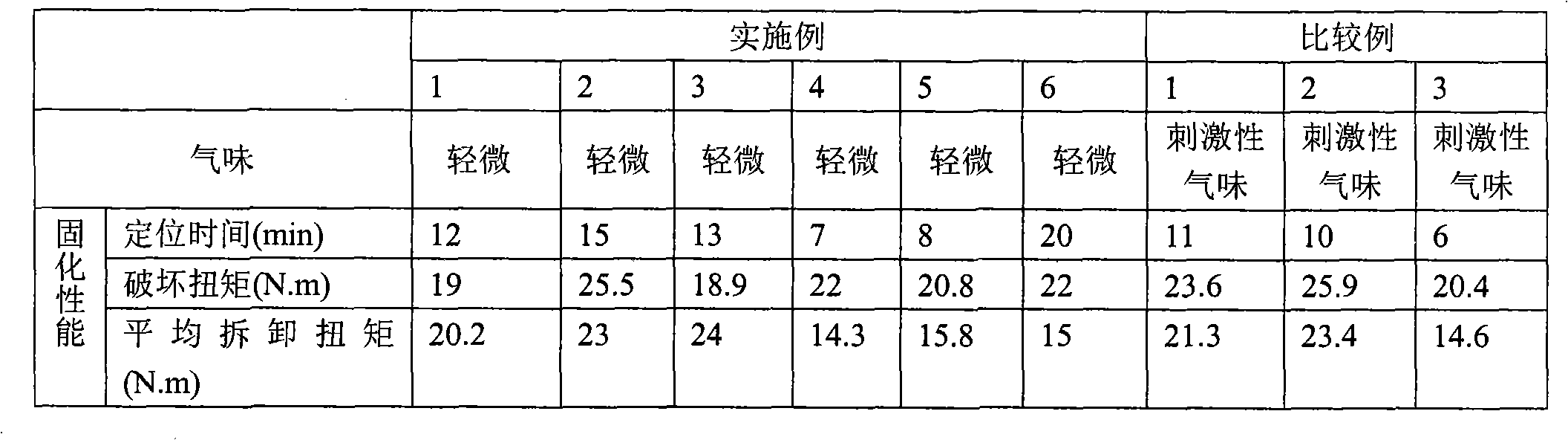

Embodiment 1

[0032] According to the number of parts by mass, 51 parts of triethylene glycol dimethacrylate and 45.67 parts of epoxy methacrylate were added to the reactor, and then 0.1 part of hydroquinone as a polymerization inhibitor, 0.1 part of chelating agent ethylenediaminetetraacetic acid di 0.15 parts of sodium, stir and heat to 60-70°C, and react for 2-3 hours. Cool to 50-55°C, add 0.45 parts of benzohydrazide, 1.1 parts of o-sulfonyl benzimide, 1.5 parts of dicumyl peroxide and 0.02 parts of 1,2,3,4-tetrahydroquinoline in sequence , and stir until completely dissolved. Finally, add 0.01 part of oil soluble red and stir evenly. After passing the inspection, it can be packaged as a finished product.

Embodiment 2

[0034] According to the number of parts by mass, 50 parts of triethylene glycol dimethacrylate and 43.9 parts of epoxy methacrylate were added to the reactor, and then 0.08 parts of polymerization inhibitor p-benzoquinone and chelating agent disodium edetate were added. 0.2 parts, stirred and heated to 60-70°C, and reacted for 2-3 hours. Cool to 50-55°C, add 0.55 parts of N-acetylphenylhydrazine, 1.55 parts of o-sulfonyl benzimide, 1.7 parts of dicumyl peroxide and 0.02 parts of 1,2,3,4-tetrahydroquinoline portion, and stir until completely dissolved. Finally, add 2 parts of fumed silica and stir evenly. After passing the inspection, it can be packaged as a finished product.

Embodiment 3

[0036] According to the number of parts by mass, 46 parts of triethylene glycol dimethacrylate and 44.54 parts of epoxy methacrylate were added to the reactor, and then 0.08 parts of hydroquinone as a polymerization inhibitor, 0.08 parts of chelating agent ethylenediaminetetraacetic acid di 0.12 parts of sodium, stir and heat to 60-70°C, and react for 2-3 hours. Cool to 50-55°C, add 0.55 parts of benzohydrazide, 1.8 parts of o-sulfonyl benzimide, 1.85 parts of 1,4-bis-tert-butylperoxycumene and 6-methyl-1 , 0.05 parts of 2,3,4-tetrahydroquinoline, stirred until completely dissolved. Finally, add 0.01 part of oil soluble blue and 5 parts of castor oil, and stir evenly. After passing the inspection, it can be packaged as a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com