Plasma reinforcement cyclic deposition method for depositing a metal silicon nitride film

A metal nitride, deposition method technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve problems such as unpopularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1. Preparation of titanium silicon nitride (TiSiN) film at 450°C by PEALD

[0064] The cycle consisted of the sequential supply of the following: TDMAT, which was bubbled through argon carrier gas at a flow rate of 25 sccm for different pulse times; argon purge gas, supplied at a flow rate of 500 sccm for 5 seconds; ammonia gas, supplied at a flow rate of 100 sccm during RF plasma generation. Flow rate supplied for 5 seconds; argon purge gas supplied for 5 seconds at a flow rate of 500 sccm; BTBAS bubbled through argon carrier gas for different pulse times at a flow rate of 25 sccm; Ar purge gas supplied for 5 seconds at a flow rate of 500 sccm; ammonia gas , supplied at a flow rate of 100 sccm for 5 seconds during RF plasma generation; and argon purge gas, supplied at a flow rate of 500 sccm for 5 seconds. The process chamber pressure was approximately 1.0 Torr, and the heater temperature was 450°C, corresponding to a wafer temperature of 395°C.

[0065] Keepi...

Embodiment 2

[0070] Example 2 A titanium silicon nitride (TiSiN) film was prepared by PEALD at 250°C

[0071] The cycle was the same as in Example 1 above, except that the heater temperature was 250°C. A heater temperature of 250°C corresponds to a wafer temperature of 235°C.

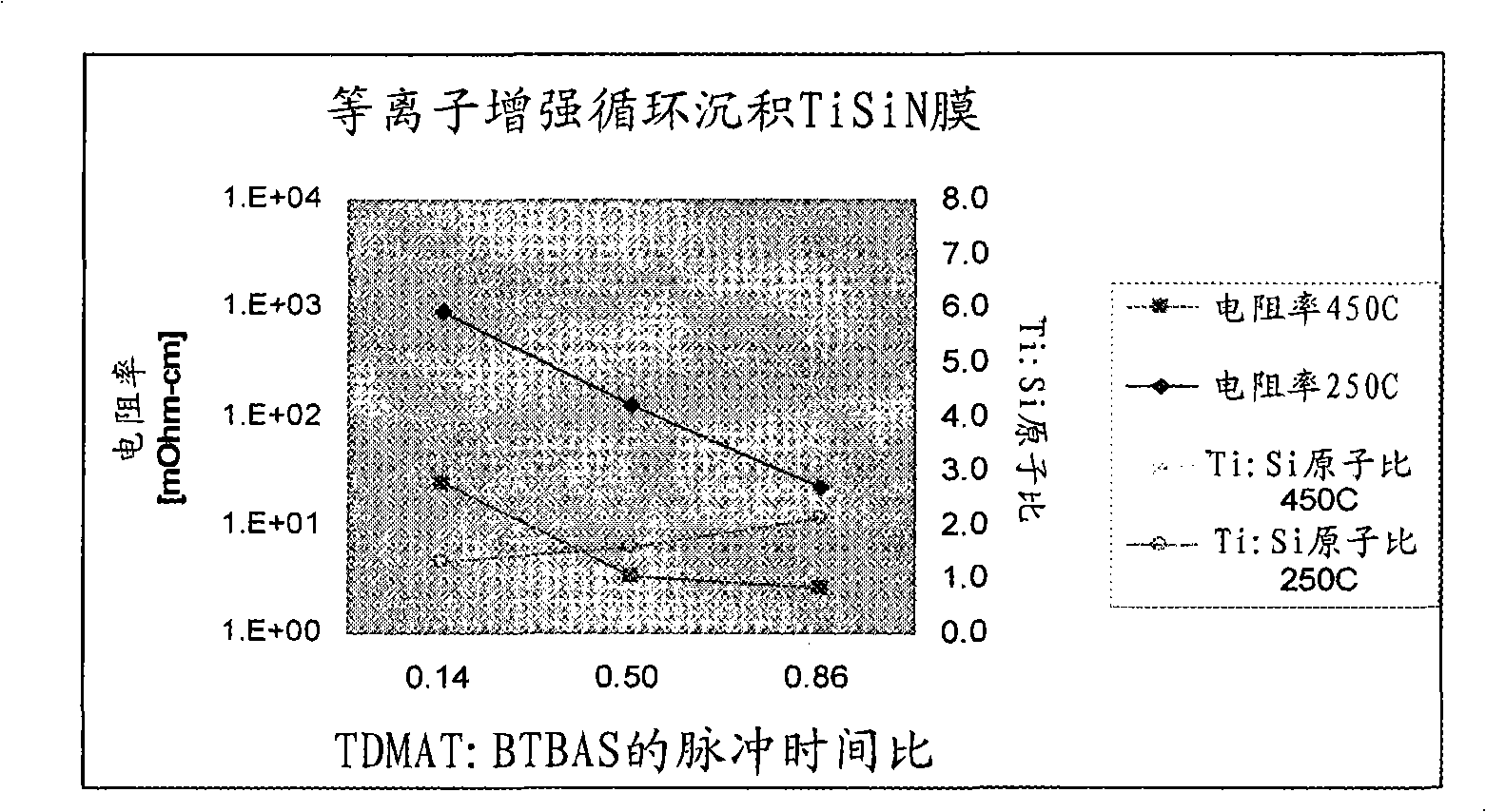

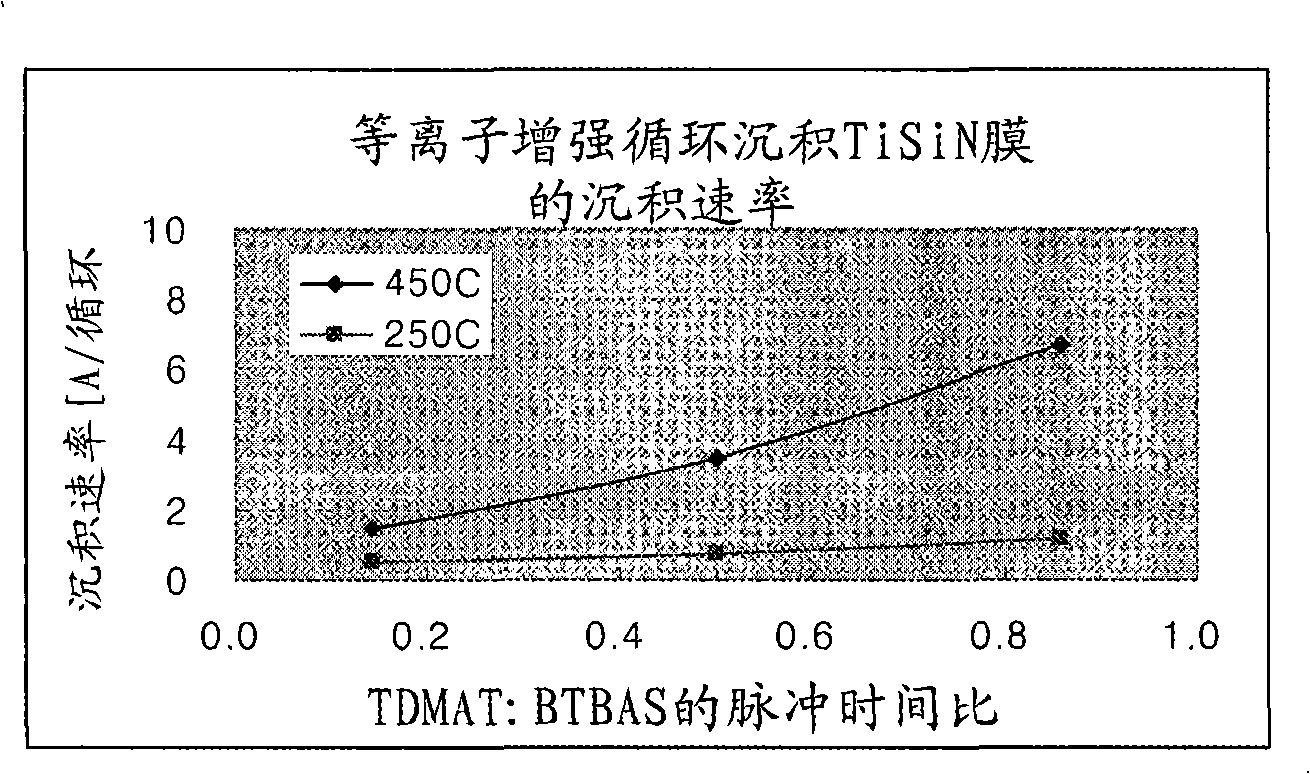

[0072] attached figure 1 and 2 The results of the tests described above are illustrated.

[0073] as attached figure 1 As shown, the resistivities of the above cases are 915.1, 123.5 and 22.5 mOhm-cm, respectively, and the RBS analysis shows that the Ti / Si ratios are 1.3, 1.6 and 2.1, respectively.

[0074] Likewise, as attached figure 2 As shown, the deposition rates of the above cases are 0.6, 0.8 and / cycle, reflecting that the above is within the ALD range. In other words, a metal silicon nitride film can be provided, which can be grown at a low process temperature.

Embodiment 3

[0075] Example 3. Fabrication of Titanium Silicon Nitride (TiSiN) Films by Thermal ALD at 250°C

[0076] The cycle consisted of the sequential supply of the following: TDMAT, bubbled through argon carrier gas at a flow rate of 25 sccm for different pulse times; argon purge gas, supplied at a flow rate of 500 sccm for 5 seconds; ammonia, at 100 sccm without RF plasma generation The flow rate of argon is supplied for 5 seconds; argon purge gas is supplied for 5 seconds at a flow rate of 500 sccm; BTBAS is bubbled through argon carrier gas for different pulse times at a flow rate of 25 sccm; argon purge gas is supplied for 5 seconds at a flow rate of 500 sccm; gas, supplied at a flow rate of 100 sccm for 5 seconds without RF plasma generation; and argon purge gas, supplied at a flow rate of 500 sccm for 5 seconds. The pressure of the process chamber is approximately 1.0 Torr, and the heater temperature of 250°C corresponds to a wafer temperature of 235°C.

[0077] Keeping the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com