Method for low-temperature preparing K0.5Na0.5NbO3 super fines

A technology of ultra-fine powder and low temperature, applied in the field of material science, can solve the problems of serious powder agglomeration, failure to obtain pure phase, and affect powder performance, etc., and achieve the effect of narrow particle size distribution, convenient industrial production, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

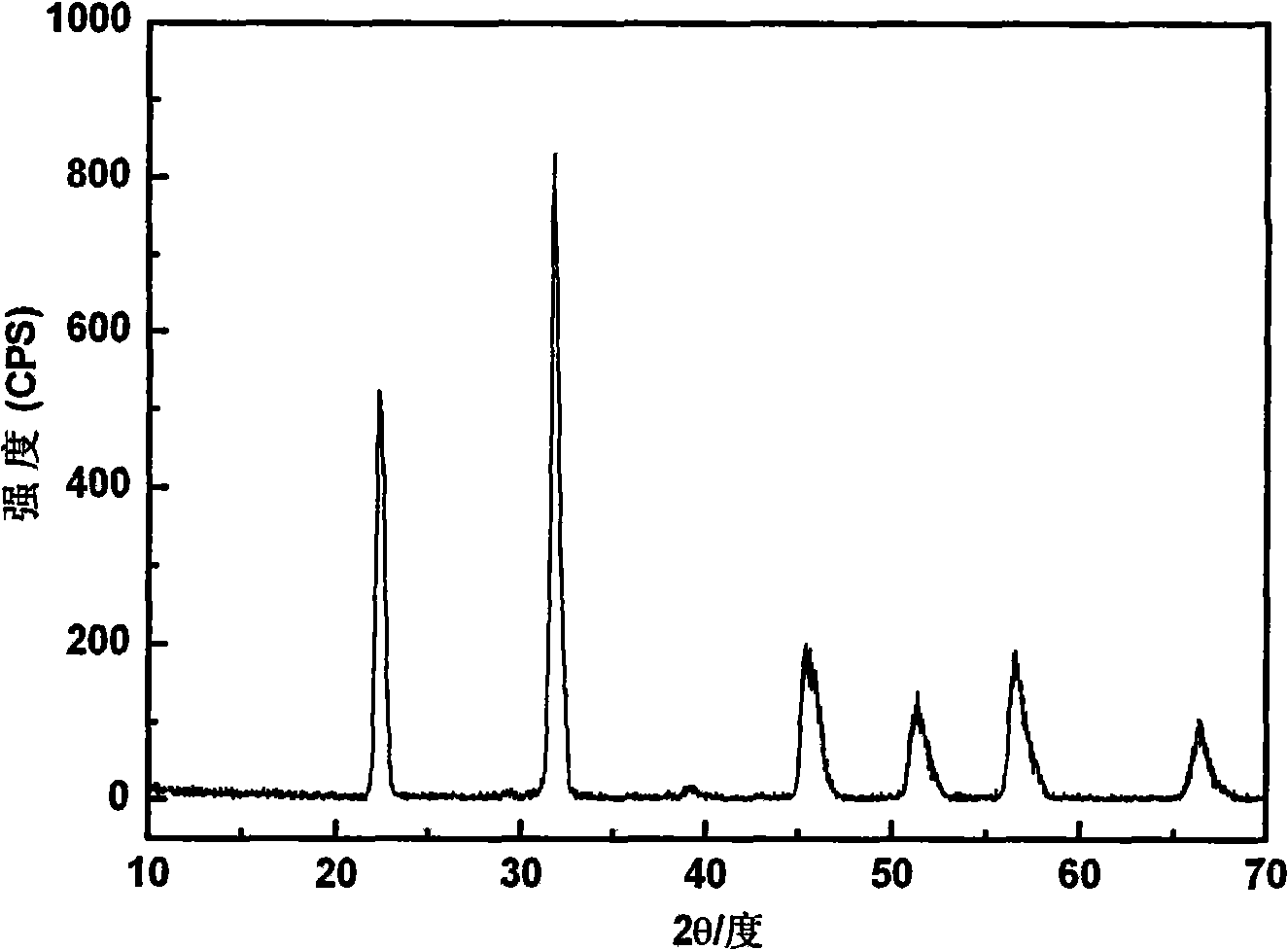

[0011] Embodiment 1: at first, according to chemical formula K 0.5 Na 0.5 NbO 3 reactant Nb 2 o 5 、Na 2 CO 3 and K 2 CO 3 The powders are mixed, and then urea, a combustion agent with 100% mass of the mixed powder, is added to the mixed powder; secondly, the mixture is put into a container, and calcined at 550°C for more than 6 hours; finally, the calcined product is ground to obtain K 0.5 Na 0.5 NbO 3 Ultrafine powder. Depend on figure 1 It can be seen that the crystal structure of the obtained powder is K 0.5 Na 0.5 NbO 3 .

Embodiment 2

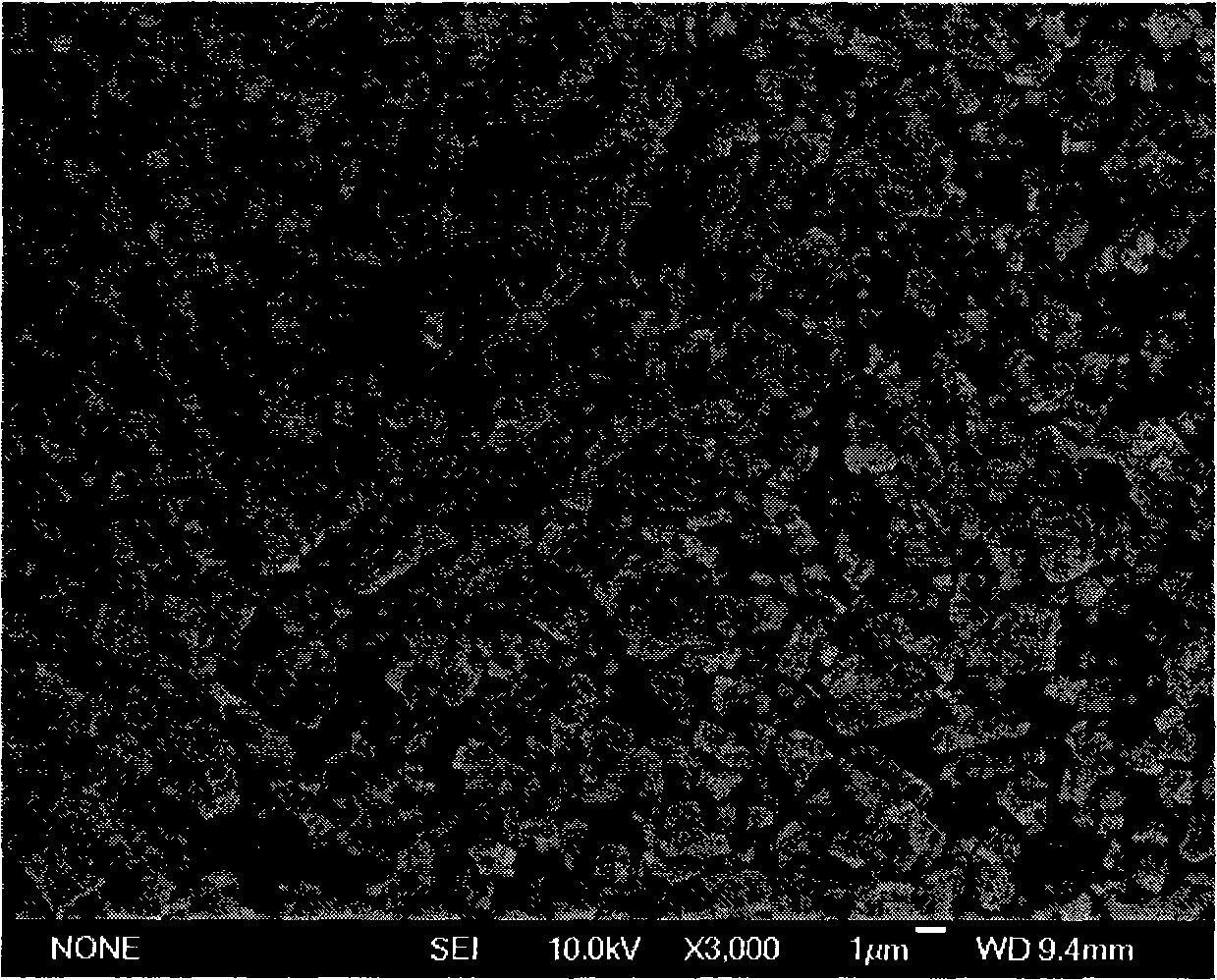

[0012] Embodiment 2: at first, according to chemical formula K 0.5 Na 0.5 NbO 3 reactant Nb 2 o 5 、Na 2 CO 3 and K 2 CO 3 The powders are mixed, and then urea, a combustion agent with 100% mass of the mixed powder, is added to the mixed powder; secondly, the mixture is put into a container, and calcined at 600°C for more than 6 hours; finally, the calcined product is finely ground to obtain K 0.5 Na 0.5 NbO 3 Ultrafine powder. Depend on figure 2 It can be seen that the particle size of the synthetic powder is small and the distribution is small, between 1 and 3 μm. The grain development is better and the agglomeration is lighter.

Embodiment 3

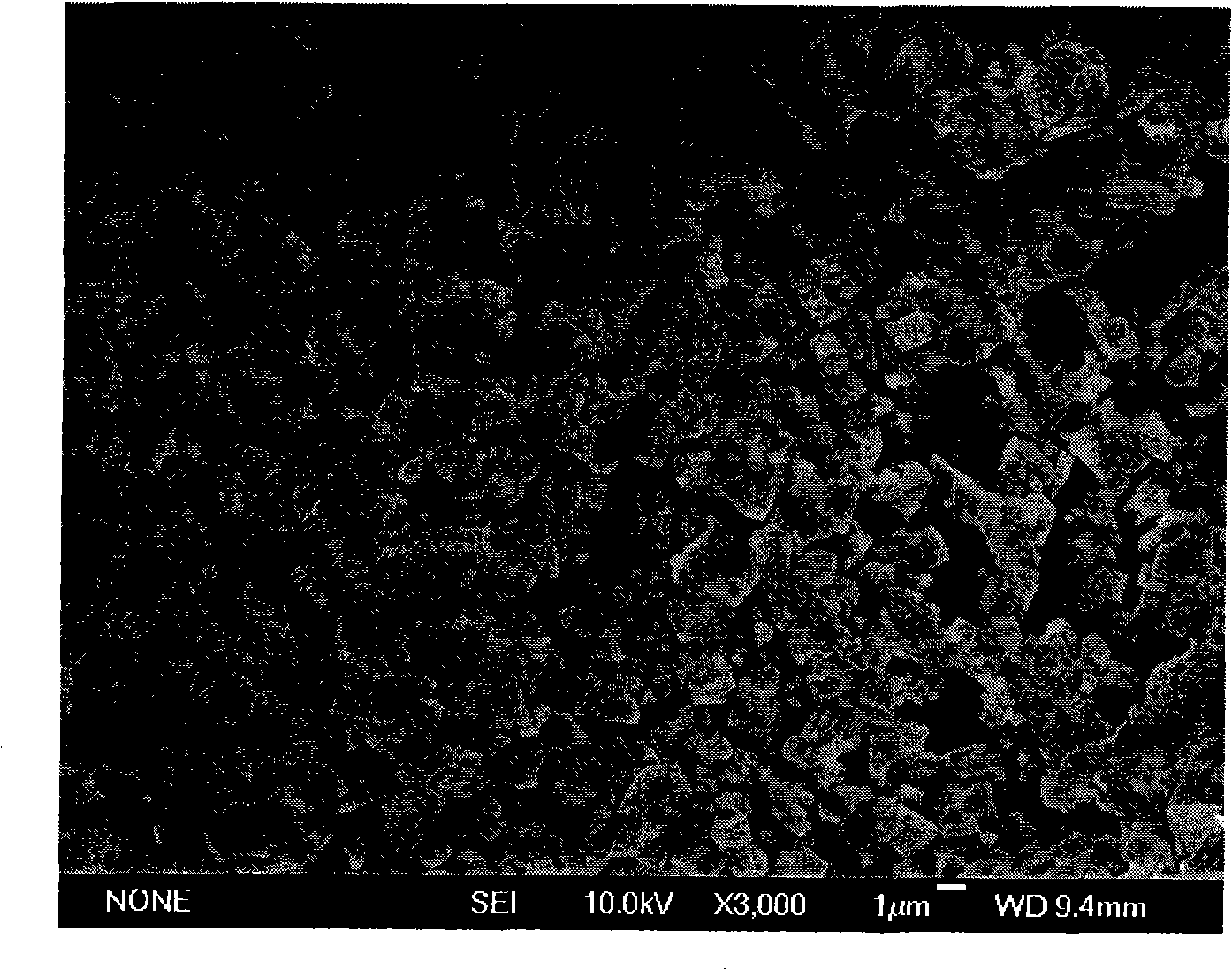

[0013] Embodiment 3: at first, according to chemical formula K 0.5 Na 0.5 NbO 3 reactant Nb 2 o 5 、Na 2 CO 3 and K 2 CO 3 Mix the powders, and then add urea, a combustion agent with a mass of 120% of the mixed powders, into the mixed powders; secondly, put the mixture in a container, and calcinate it at 550°C for more than 6 hours; finally, grind the calcined product finely to obtain K 0.5 Na 0.5 NbO 3 Ultrafine powder. Depend on image 3 It can be seen that the particle size of the synthetic powder is small and the distribution is small, between 1 and 3 μm. The grain development is better and the agglomeration is lighter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com