Bio-contact oxidizing treatment device using standard box

A biological contact and oxidation treatment technology, applied in the field of environmental protection, can solve problems such as inability to adapt to sewage discharge source sewage treatment, problems of adaptability, different treatment processes, etc., to achieve good treatment effects, reduce site occupancy, and simplify the production process. and production cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

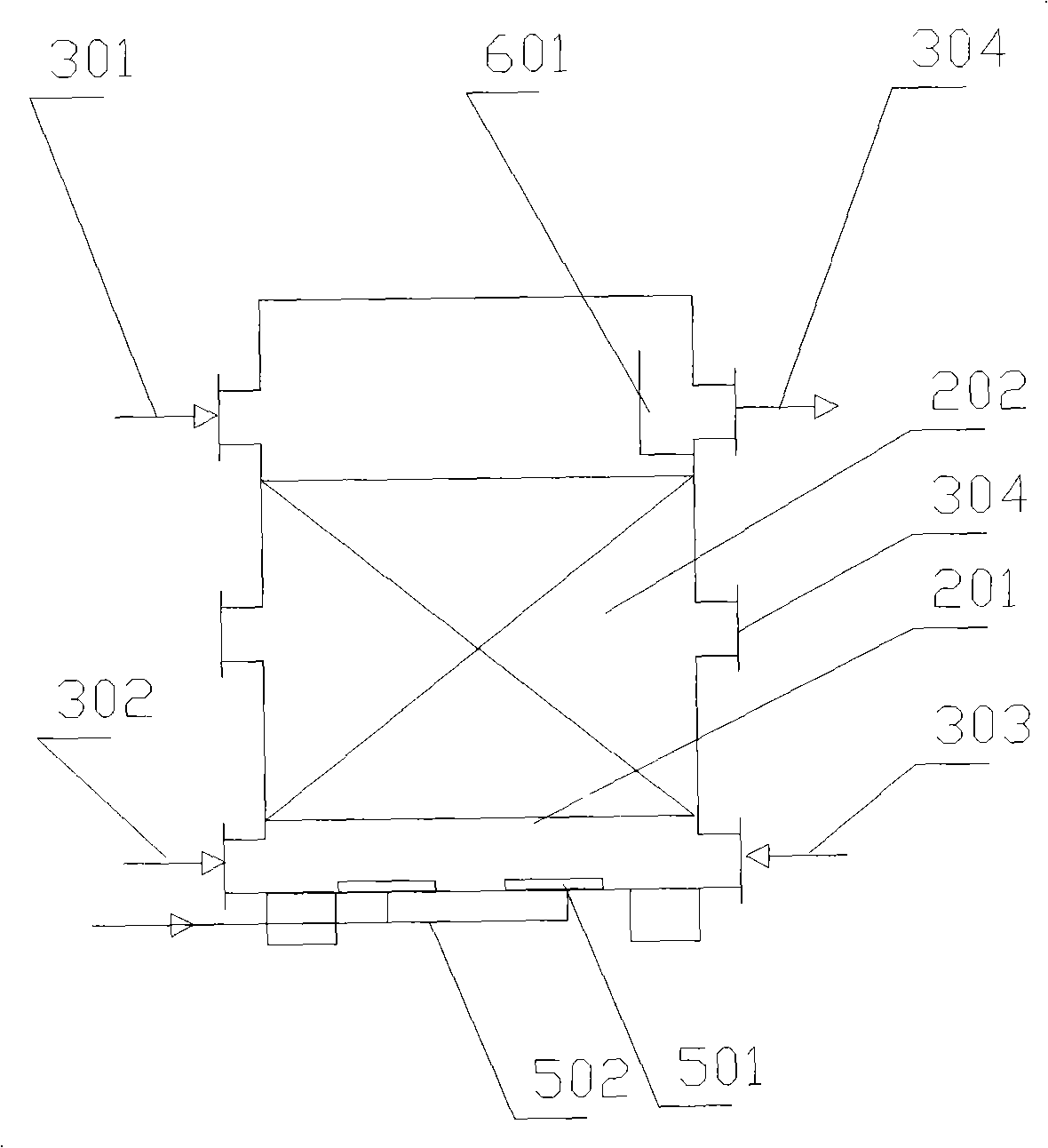

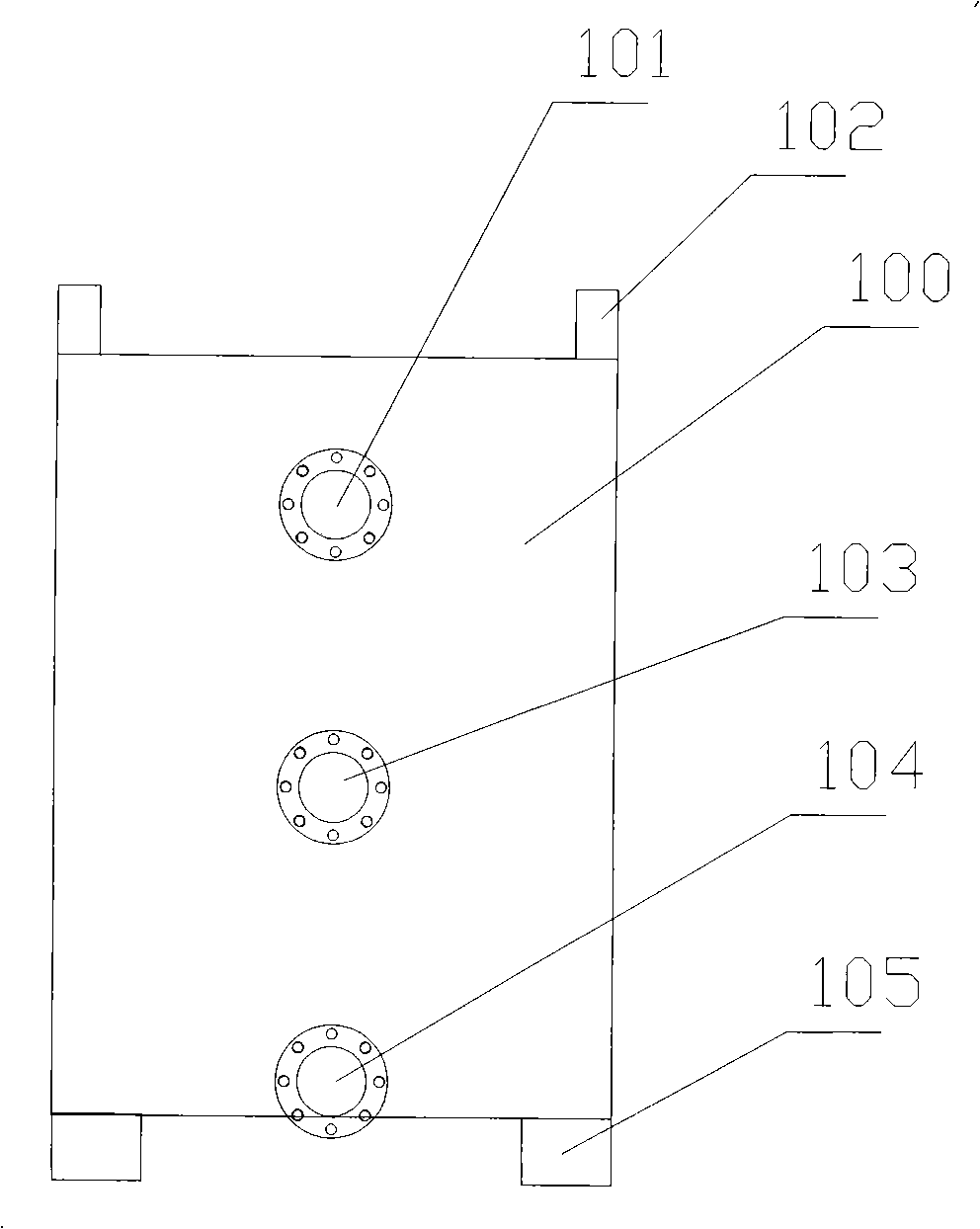

[0009] see figure 1 and figure 2 , the present invention provides a biological contact oxidation treatment device using a standard box body, including a standardized box body 100, the box body is rectangular, and its two ends are respectively provided with three identical flanged connections. The short pipes 101, 103, 104 are provided with a fixed packing bed inside the box.

[0010] The packing bed is located between the upper and lower connecting short pipes, thereby facilitating the water inlet and outlet of the upper and lower connecting short pipes.

[0011] Above and below the packed bed are orifice plates, grid-like plates, grids or grids with wire mesh 201 for supporting fillers, and the orifice plates, grid-like plates, grids or grids with wire mesh The grid is mounted on the wall inside the box.

[0012] The packing 202 on the packing bed can be a rectangular or cylindrical plastic frame packing or a honeycomb packing, or a rectangular or cylindrical plastic fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com