Closed type automatic industry-parts cleaning oil-sealing device

A fully enclosed, oil-sealing machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, distillation and separation, etc., can solve the problems of inability to recycle repeatedly, human injury, and increase labor intensity, so as to reduce the damage to human body. , the effect of reducing environmental pollution and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

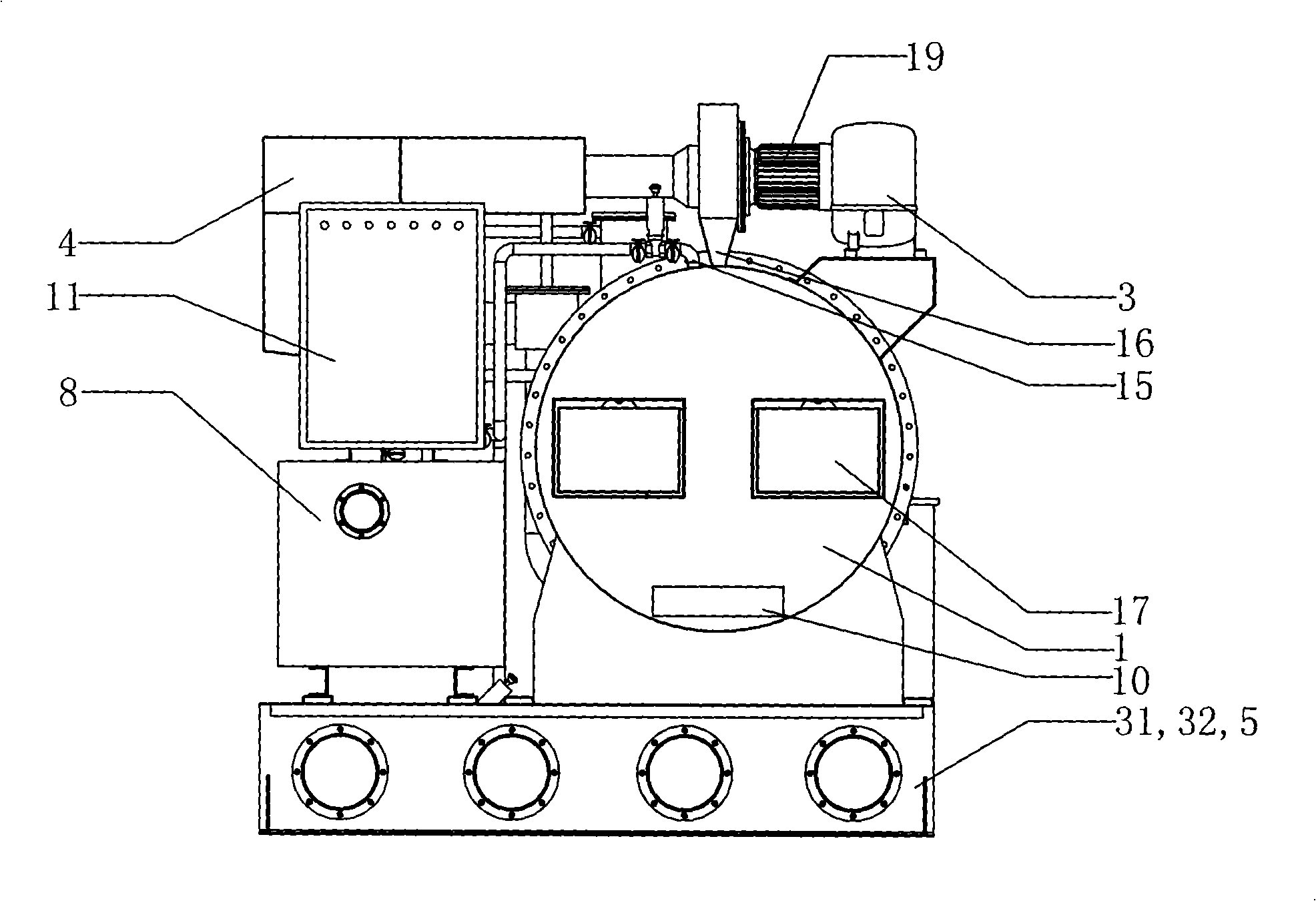

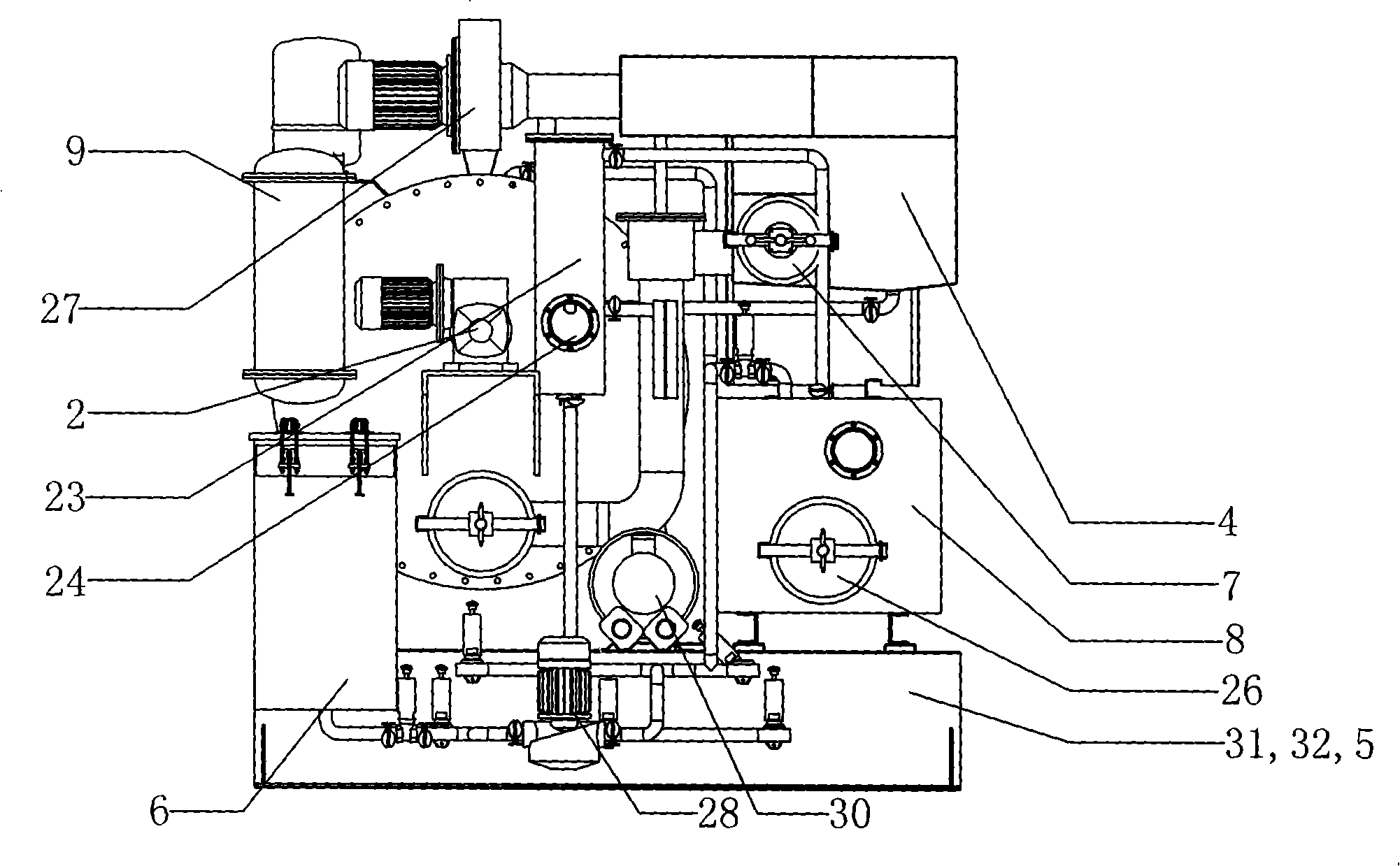

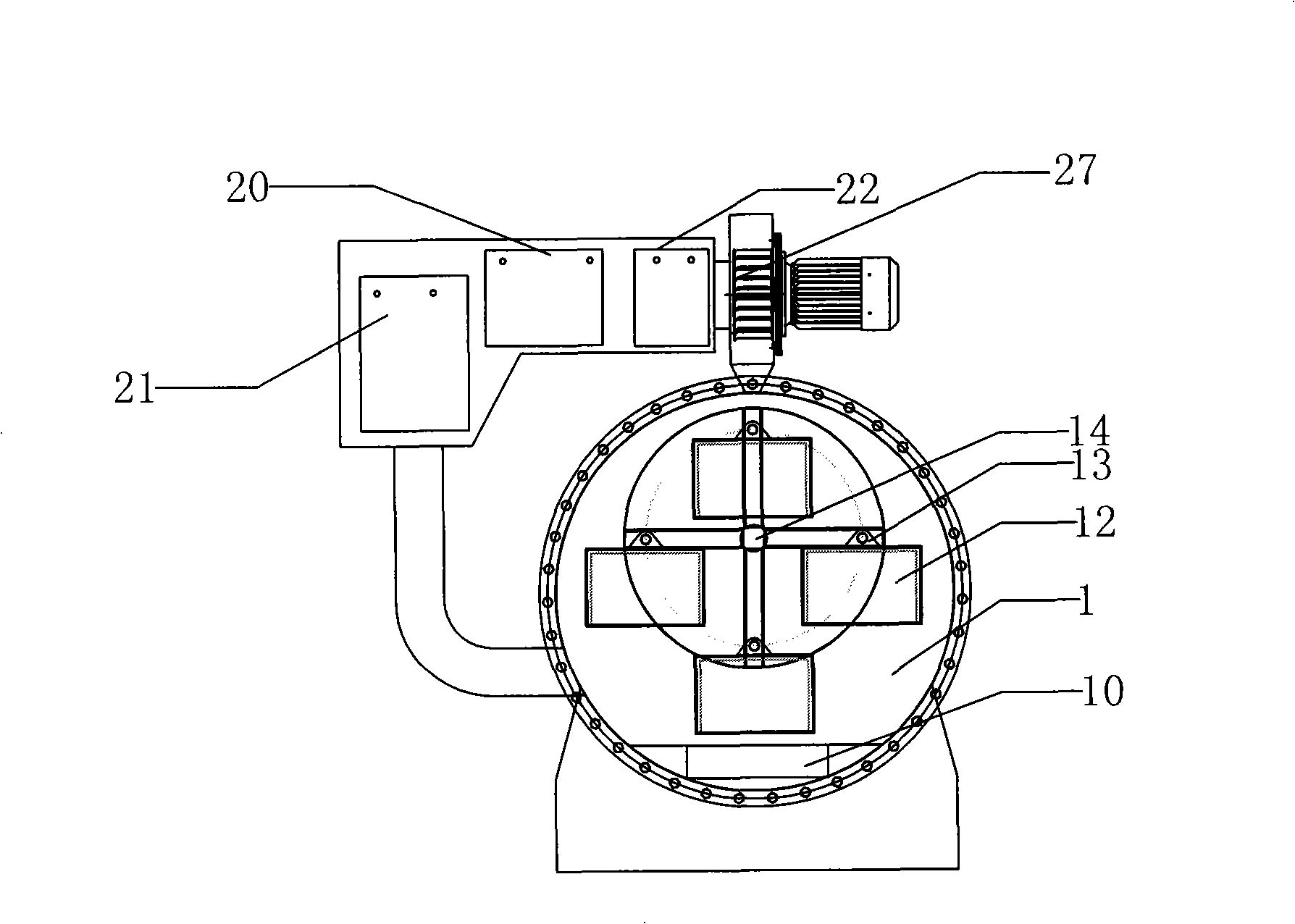

[0016] like Figure 1-3 As shown, the fully enclosed automatic industrial parts cleaning oil seal machine described in the utility model includes a cleaning chamber 1, a main transmission system 2, a refrigeration system 3, an air passage drying recovery system 4, liquid storage tanks 31 and 32, and a grease tank 5 , filters 6 and 7, distillation recovery system or vacuum distillation recovery system, carbon adsorption recovery system 9, ultrasonic generator 10 and electrical control system 11, among them.

[0017] The cleaning chamber 1 and the main transmission system 2 are used to load the parts to be cleaned. The parts cleaning, drying and oil sealing are all completed in the cleaning chamber; the cleaning chamber 1 is a cylinder, and the axial direction is horizontally placed in the grease tank 5 and the liquid storage tank. 31 and 32, the ultrasonic generating device 10 is arranged at the bottom of the cleaning chamber 1, and the electrical control system 11 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com