Synthesis of DMF and device

A heat exchange device and cooling medium technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of low synthesis efficiency and short production cycle, reduce the frequency of equipment start-up and stop, and improve the reaction Efficiency, reduction of maintenance and cleaning costs and the effect of pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

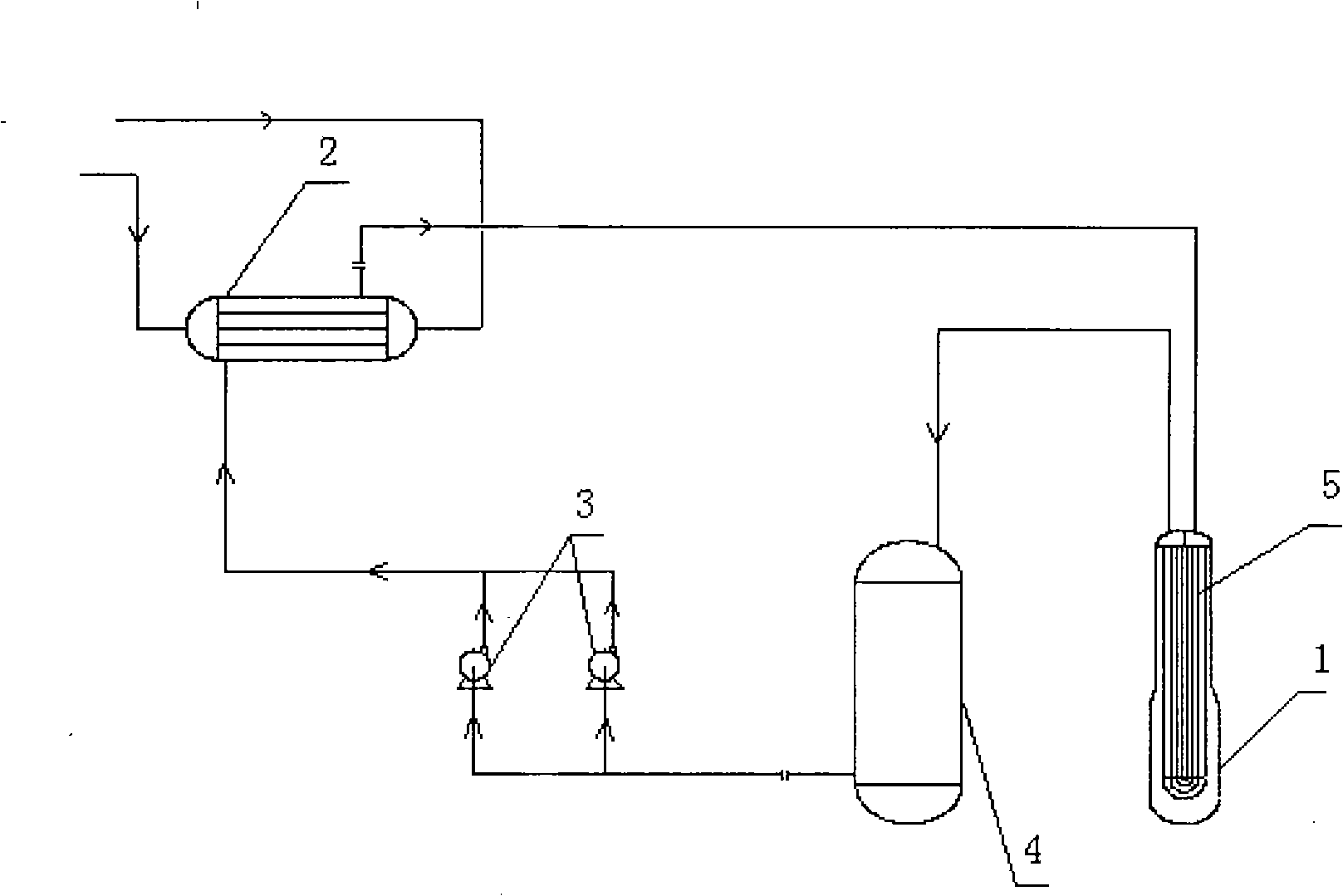

[0026] Such as figure 1 As shown, the DMF reaction device is composed of a DMF reactor 1, a desalinated water heat exchanger 2, a desalted water circulation pump 3 (one of which is a standby pump), and a buffer tank 4; wherein the outlet of the DMF reactor 1 cooling medium is connected to the buffer tank, The buffer tank is connected to the desalinated water circulating pump 3, and the circulating pump 3 is connected to the desalinated water heat exchanger 2, and the desalted water heat exchanger 2 is connected to the cooling medium inlet of the DMF reactor 1. Wherein the reactor 1 is provided with a U-shaped heat exchange tube 5 .

[0027] In the reactor, the outside of the U-shaped tube 5 is a mixed liquid phase such as dimethylamine, sodium methoxide methanol solution, etc. CO bubbles through the sparger to react with dimethylamine to produce DMF; desalted water is used as the cooling medium of the DMF reactor, and it goes through U The tube side of type tube 5 conducts he...

Embodiment 2

[0029] In the reactor, outside the U-shaped tube is a mixed liquid phase such as dimethylamine, sodium methoxide and methanol solution, and CO is bubbled through the sparger to react with dimethylamine to produce DMF; desalted water is used as the cooling medium of the DMF reactor, and it follows a U-shaped The tube side and the liquid phase and gas phase in the reactor conduct heat exchange between the walls, absorb the heat generated by the synthesis reaction, and at the same time increase the temperature of the desalted water; the temperature of the desalted water entering the reactor is 90 ° C, and the temperature of the exiting reactor reaches 94 ° C. The desalinated water is sent to the buffer tank, through the circulation pump at 500m 3 / h flow rate to the desalinated water heat exchanger. The desalinated water goes through the shell side and exchanges heat with the tube side circulating water. After being cooled to 90°C by the circulating water, it is sent to the cooli...

Embodiment 3

[0031] In the reactor, outside the U-shaped tube is a mixed liquid phase such as dimethylamine, sodium methoxide and methanol solution, and CO is bubbled through the sparger to react with dimethylamine to produce DMF; desalted water is used as the cooling medium of the DMF reactor, and it follows a U-shaped The tube side and the liquid phase and gas phase in the reactor conduct heat exchange between the walls, absorb the heat generated by the synthesis reaction, and at the same time increase the temperature of the desalted water; the temperature of the desalted water entering the reactor is 93 ° C, and the temperature of the exiting reactor reaches 98 ° C. The desalinated water is sent to the buffer tank, through the circulation pump at 550m 3 / h flow rate to the desalinated water heat exchanger. The desalted water goes through the shell side, exchanges heat with the tube side circulating water, is cooled to 93°C by the circulating water, and then sent to the cooling medium in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com