A method for treating flue gas

A flue gas treatment and flue gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as low operating costs, and achieve the effects of improving operating reliability, low operating costs, and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

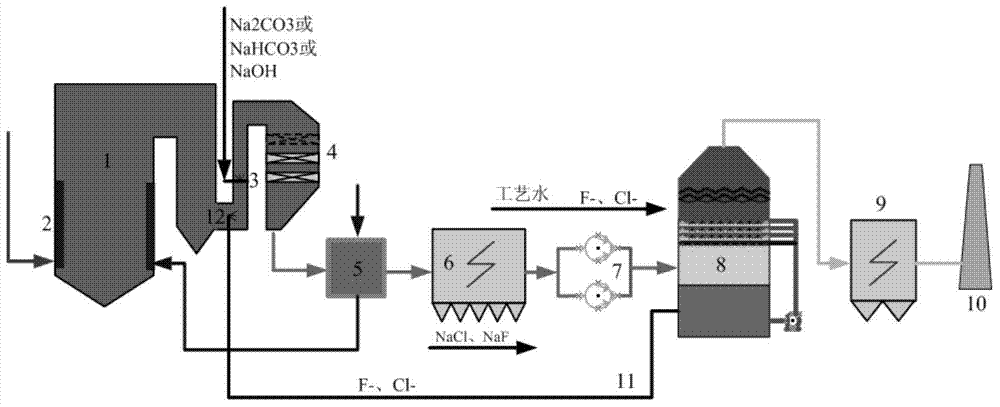

[0033] according to figure 1 In the flow chart shown, the flue gas produced by the combustion of 100 parts by weight of Shenhua bituminous coal in the boiler 1 enters the flue, and an injector 3 with a high-efficiency atomizing nozzle is arranged in the flue, and the injector 3 injects 1.2 wt. The concentration of part is the atomized alkaline solution (Na 2 CO 3 and NaHCO 3 Mixed aqueous solution, as Na 2 CO 3 ), and cooperate with the flue gas flow equalization device to make the atomized solution particles and the flue gas evenly mixed, the flue gas passes through the flue provided with the injector 3 and then continues to enter the SCR denitrification device for denitrification, and then enters the air preheater 5 in turn for denitrification Cool down, enter the electrostatic precipitator 6 for dust removal (remove the solids in the flue gas (including the solid salt of F and Cl generated)), and enter the desulfurization absorption tower 8 through the induced draft fan...

Embodiment 2

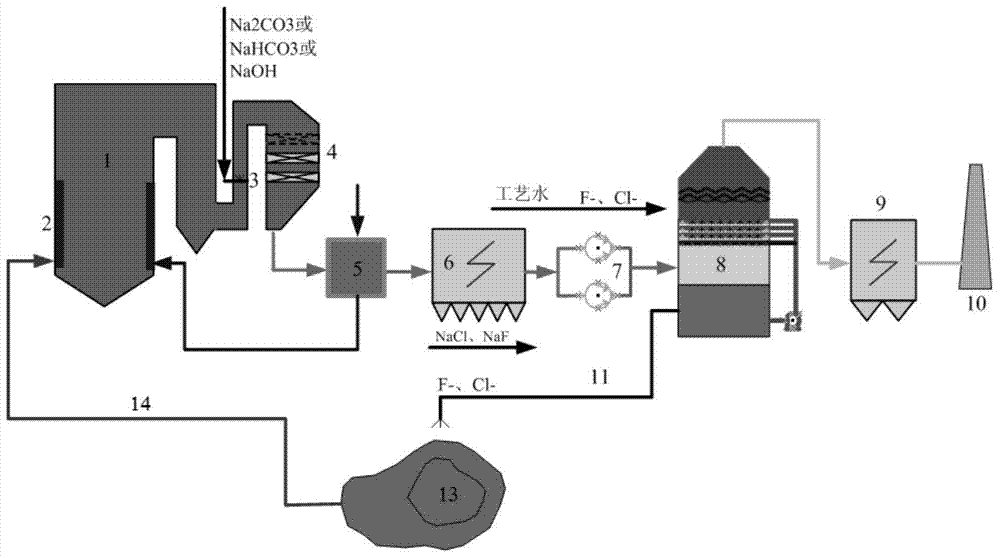

[0036] according to figure 2 As shown in the flow chart, the flue gas produced by the combustion of 100 parts by weight of Shenhua bituminous coal in the boiler 1 enters the flue, and an injector 3 with a high-efficiency atomizing nozzle is arranged in the flue, and the injector 3 injects 1.1 wt. The concentration of one part is the atomized alkaline solution (aqueous solution of NaOH, calculated as NaOH) of 5% by weight, and preferably cooperates with the flue gas equalizing device so that the atomized solution particles are uniformly mixed with the flue gas, and the flue gas passes through and is provided with an injector After the flue of 3, continue to enter the SCR denitration device for denitrification, then enter the air preheater 5 for cooling, and then enter the electric precipitator 6 for dust removal (remove the solids in the flue gas (including the solid salts of F and Cl generated) ), enter the desulfurization absorption tower 8 by induced draft fan 7 and carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com