Dual-alkali flue gas desulfurization device and desulfurization method

The technology of desulfurization equipment and double alkali method is applied in the field of atmospheric environmental protection, which can solve the problems of unsuccessful sodium sulfite regeneration, unsustainable desulfurization efficiency, and increase of sodium hydroxide input, so as to eliminate scaling and blockage in the tower, avoid huge waste, The effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

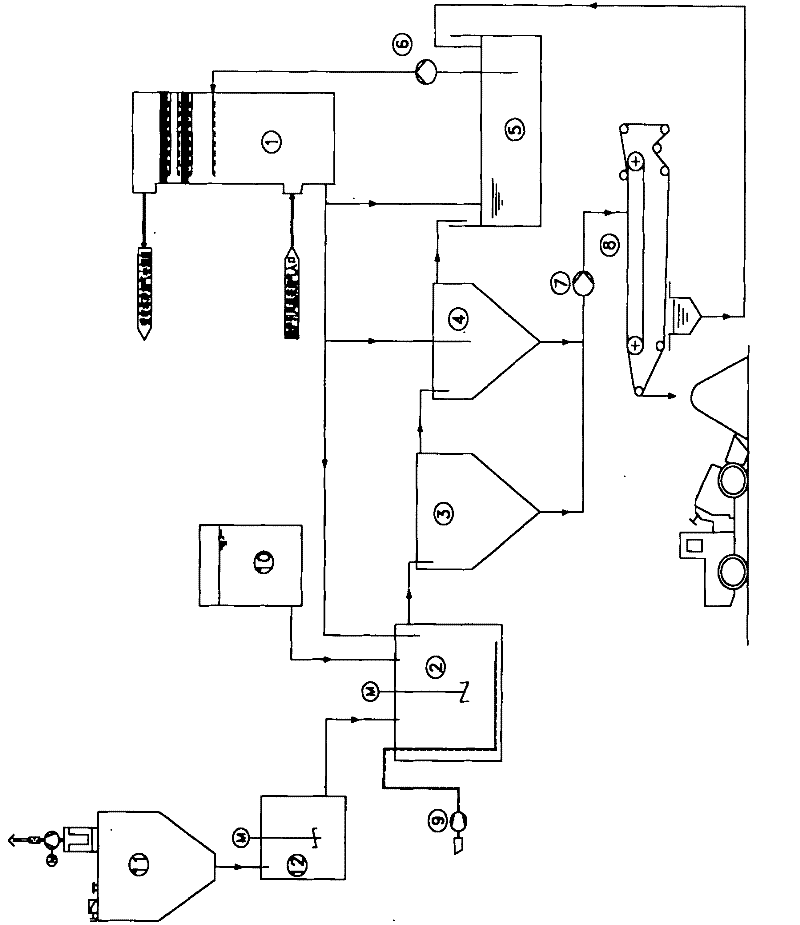

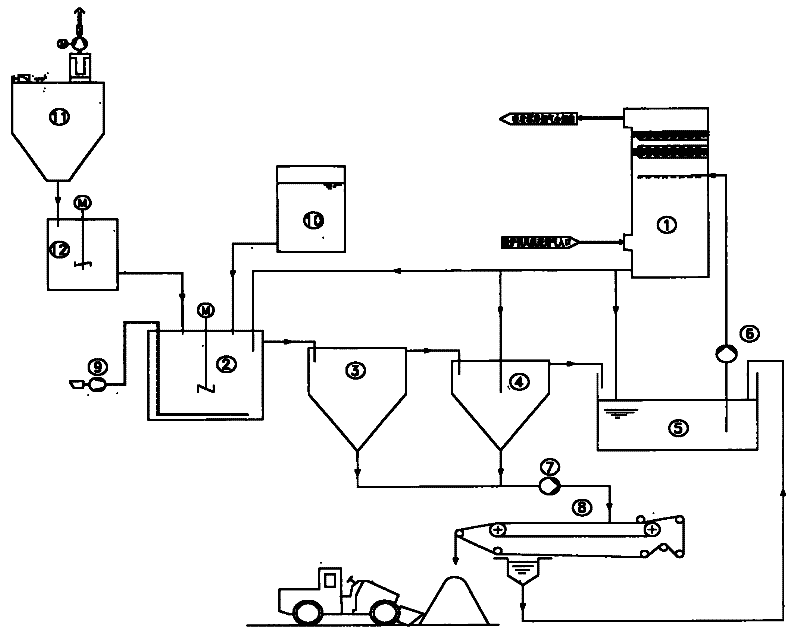

[0016] The accompanying drawing is a specific embodiment of the present invention. This embodiment includes an absorption tower 1, a liquid alkali storage tank 10, and a quicklime powder silo 11. The quicklime powder silo 11 is sequentially connected with a lime slurry tank 12, an oxidation regeneration tank 2, a primary sedimentation tank 3, a secondary sedimentation tank 4 and a circulation tank. 5. The bottom of the absorption tower 1 is provided with pipes leading to the oxidation regeneration tank 2, the secondary sedimentation tank 4 and the circulation tank 5 respectively. The bottom outlet of the tank 3 and the secondary sedimentation tank 4 leads to the horizontal vacuum belt filter 8 through the gypsum slag discharge pump 7; the oxidation regeneration tank 2 is connected with an oxidation fan 9; There is a mixing tank.

[0017] The dual-alkali flue gas desulfurization equipment mainly includes the following sub-systems: A) absorbent preparation system, including liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com