Nanometer exterior wall coating

A technology of exterior wall coatings and nanomaterials, applied in coatings, latex paints, etc., can solve the problems of easy aging of coatings, resistance to washing, poor weather resistance, etc., to improve pollution resistance, prevent mold growth, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

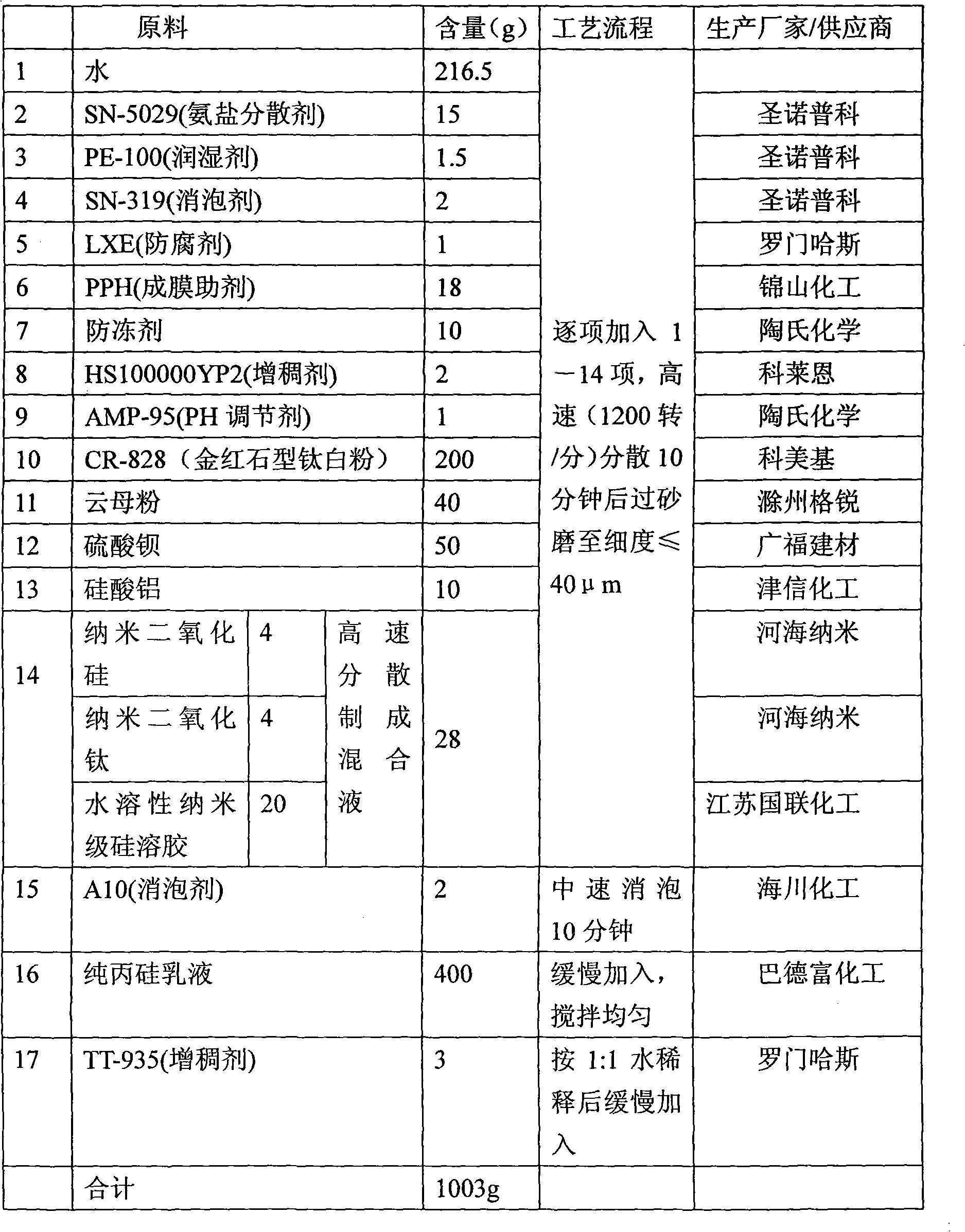

[0034] Nano exterior wall paint (white) formula composition:

[0035]

[0036] The nano-silica and nano-titanium dioxide bought from the market are dispersed in the water-soluble nano-scale silica sol carrier by high-speed shearing, and the materials are added according to the formula, stirred, sanded, emulsified, painted, and filtered. The obtained product is a white exterior wall paint, and the test results: 41,000 times of cleaning and scrubbing the inferior material without showing the bottom; artificial weather aging resistance test: 1,000 hours: the test result of the mold resistance of the paint film: the anti-〔anti-〕 mold effect is remarkable, and the product It can effectively prevent the growth of mold after storage and painting walls.

Embodiment 2

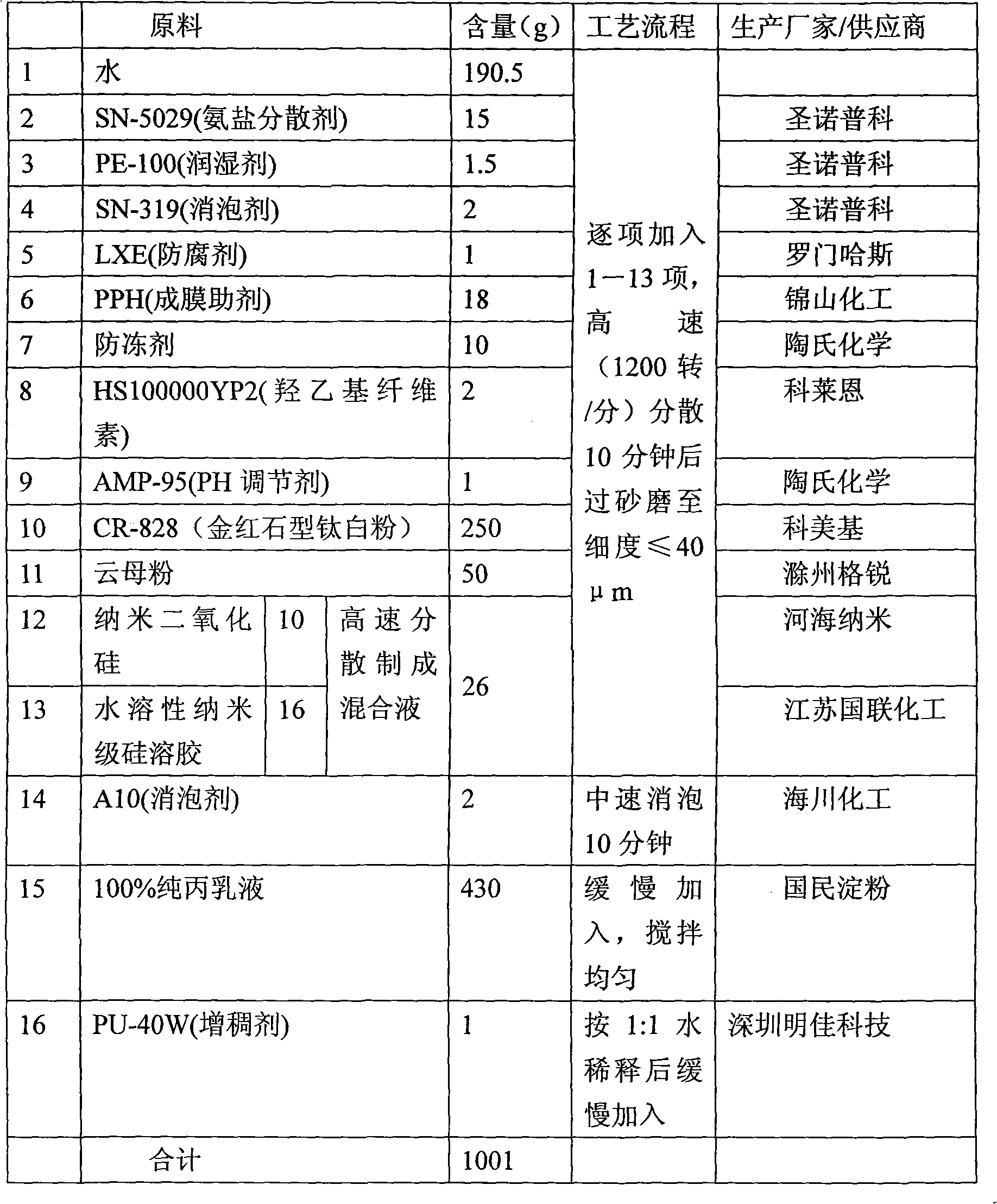

[0037] Embodiment 2, nano exterior wall paint [white] formula composition:

[0038]

[0039] The nano-silica and nano-titanium dioxide bought from the market are dispersed in the water-soluble nano-scale silica sol by high-speed shearing, and the materials are added according to the formula, stirred, sanded, emulsified, painted, and filtered. The resulting product is a white exterior paint. The test results: 43,000 times of cleaning and scrubbing without showing the bottom; artificial weather aging resistance test: 0.98 thousand hours: the test result of the mold resistance of the paint film: the effect of preventing (anti) mold is remarkable, and the product can effectively prevent it after storage and coating the wall The growth of mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com