Light and electricity co-transmission fiber and manufacturing method thereof

An optical fiber and fiber technology, which is applied in the field of photoelectric conduction and can solve problems such as difficulty in supporting photoelectric composite functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

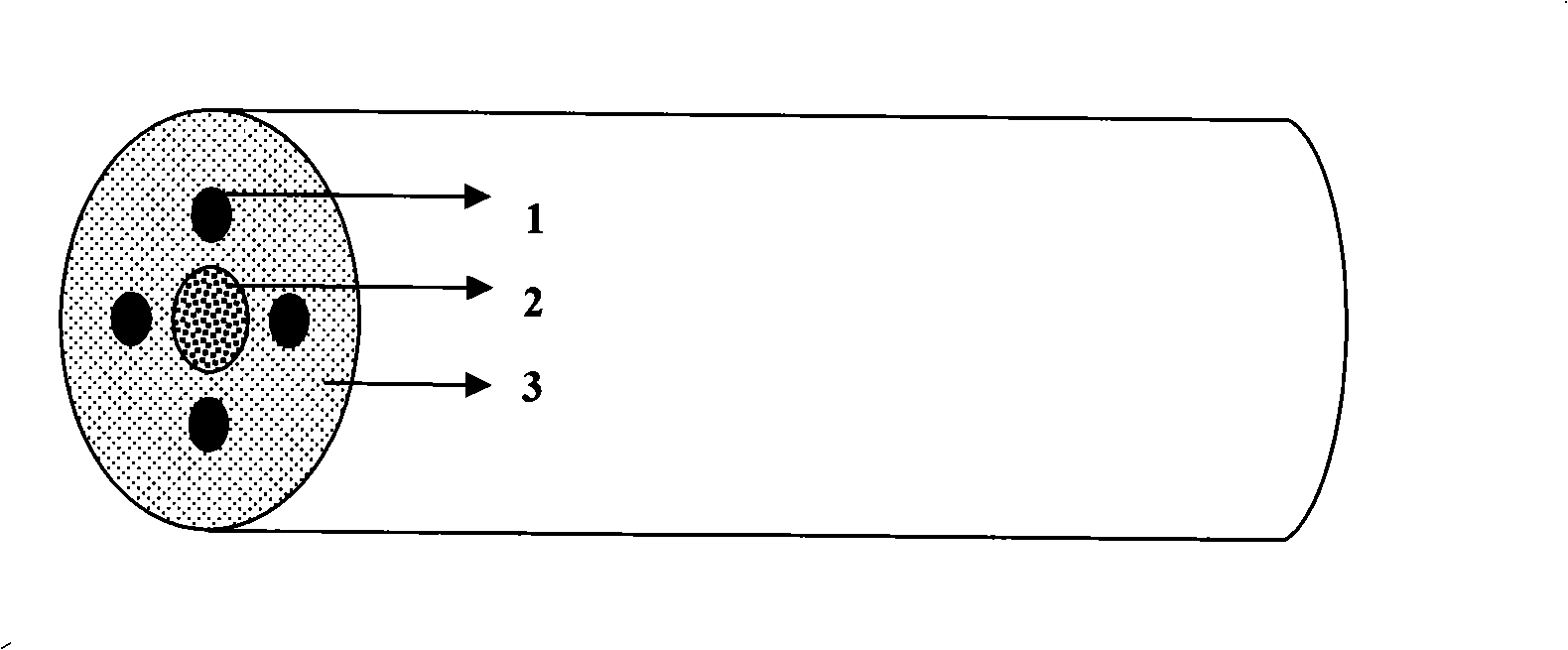

[0023] The photoelectric simultaneous transmission fiber structure of this embodiment is as follows figure 1 As shown, its inner light guiding part is an optical fiber 2, and the outer optical fiber 2 is an outer wrapping layer 3 made of an organic polymer material. One or more metal wires 1 are embedded in the outer wrapping layer 3 . The optical fiber 2 can be any existing optical fiber with a diameter less than 1 mm, such as single-mode or multi-mode silica optical fiber, sulfide optical fiber or plastic optical fiber. The organic polymer is a thermoplastic organic polymer material, such as polymethyl methacrylate (PMMA, Polymethyl methacrylate), polyetherimide (PEI, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com