Electromagnetic compatible wood based composite material for engineering and method preparing the same

A composite material and wood-compatible technology, which is applied in the field of functional composite wood-based panel preparation, can solve the problems of few researches on absorbing materials, achieve the effect of improving the secondary reflection problem, high shielding efficiency, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

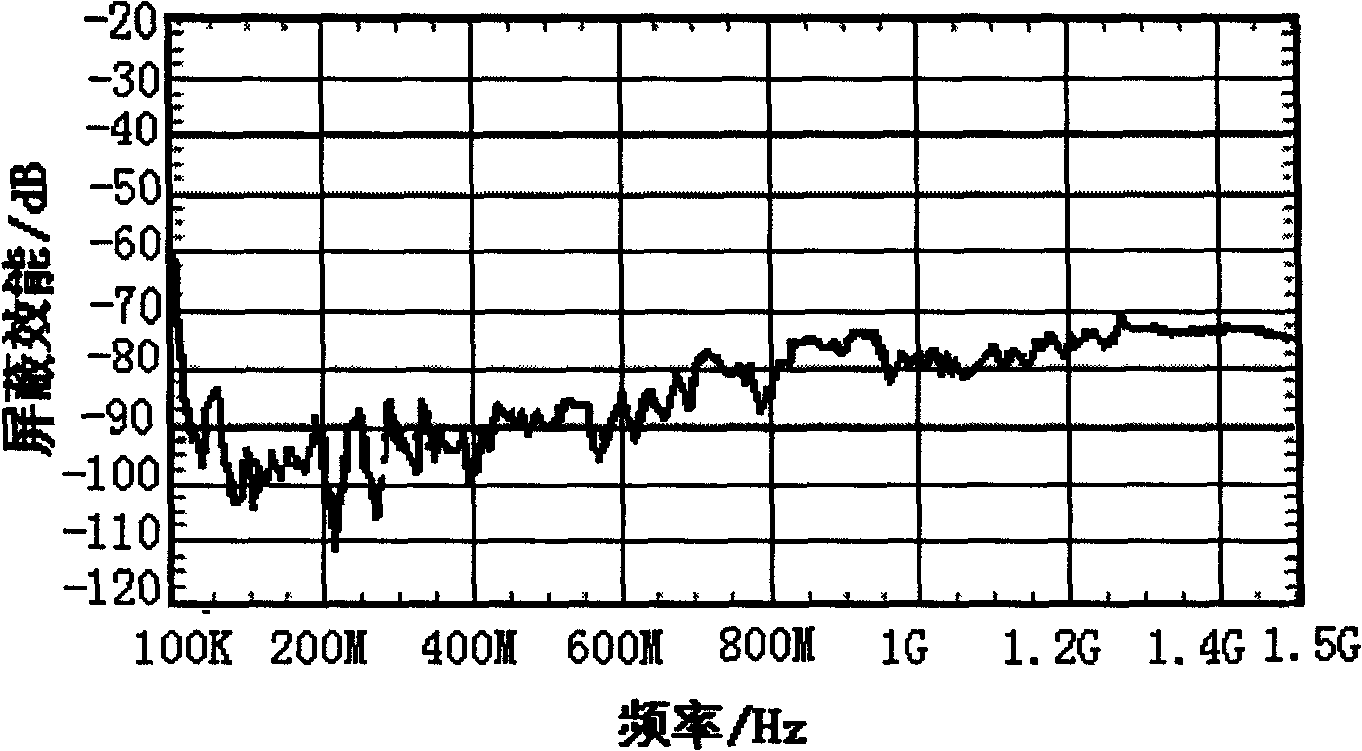

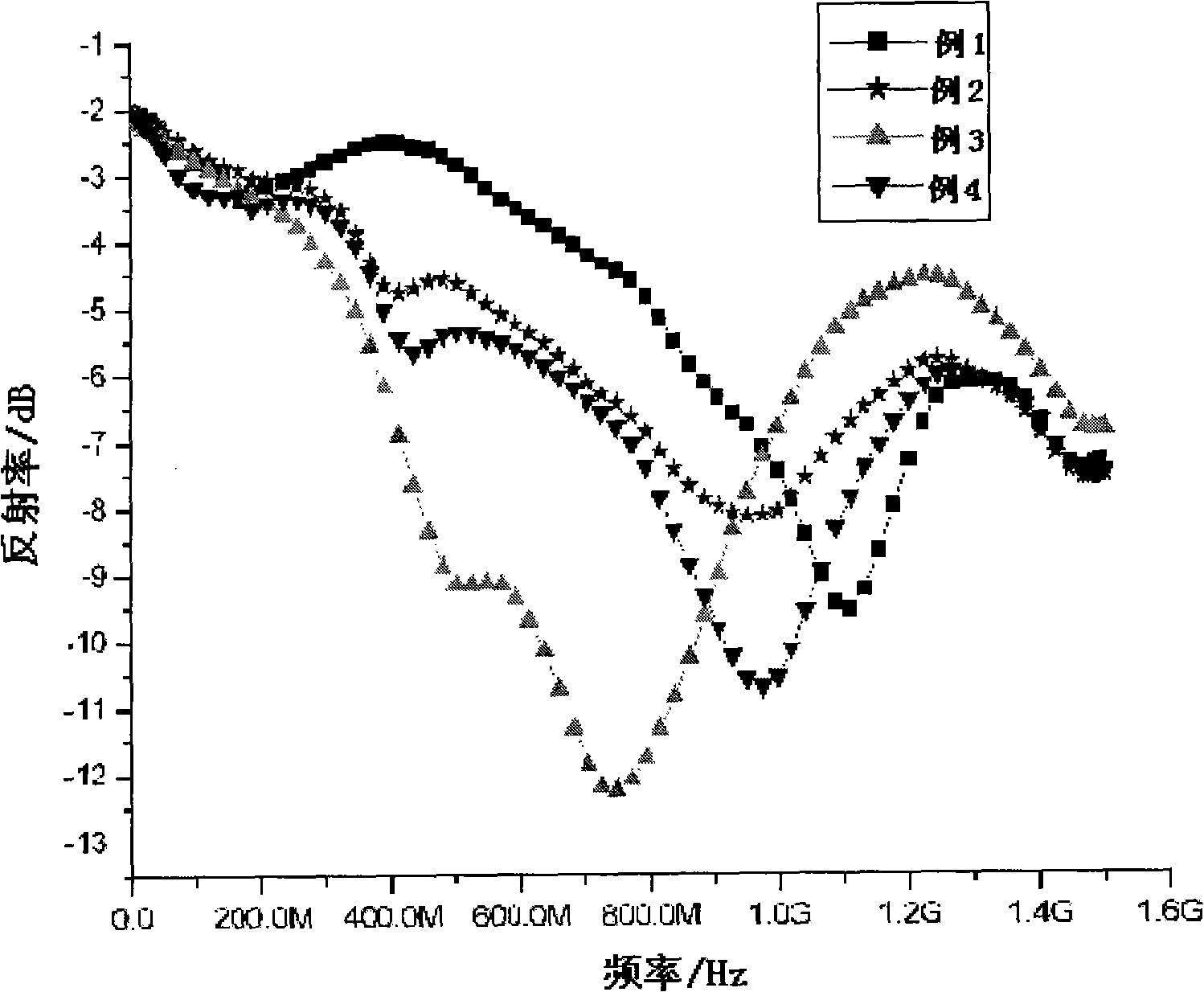

Embodiment 1

[0028] Example 1: 10 μm thick copper foil is glued to 3mm thick medium density fiberboard, epoxy resin E-51 is used as adhesive, polyamide resin 650 is used as curing agent, the mass ratio of the two is 1:1, and the bonding pressure is 0.1 MPa, glue amount is 80g / m 2 , the hot-pressing temperature is 60° C., and the hot-pressing time is 5 min. The wave-absorbing plate is a single layer, the substrate is silicone rubber, and the curing agent is composed of a crosslinking agent and a catalyst. The crosslinking agent is tetraethyl orthosilicate, the catalyst is dibutyltin dilaurate, and the mass ratio of silicone rubber to curing agent is 95: 5. The mass fraction of silicone rubber and curing agent is 20%, the absorber is MnZn ferrite, the mass fraction is 80%, and the thickness of the wave-absorbing plate is 1mm. The wave-absorbing sheet is glued to the wood board, using epoxy resin E-51 as adhesive, polyamide resin 650 as curing agent, the mass ratio of epoxy resin to curing a...

Embodiment 2

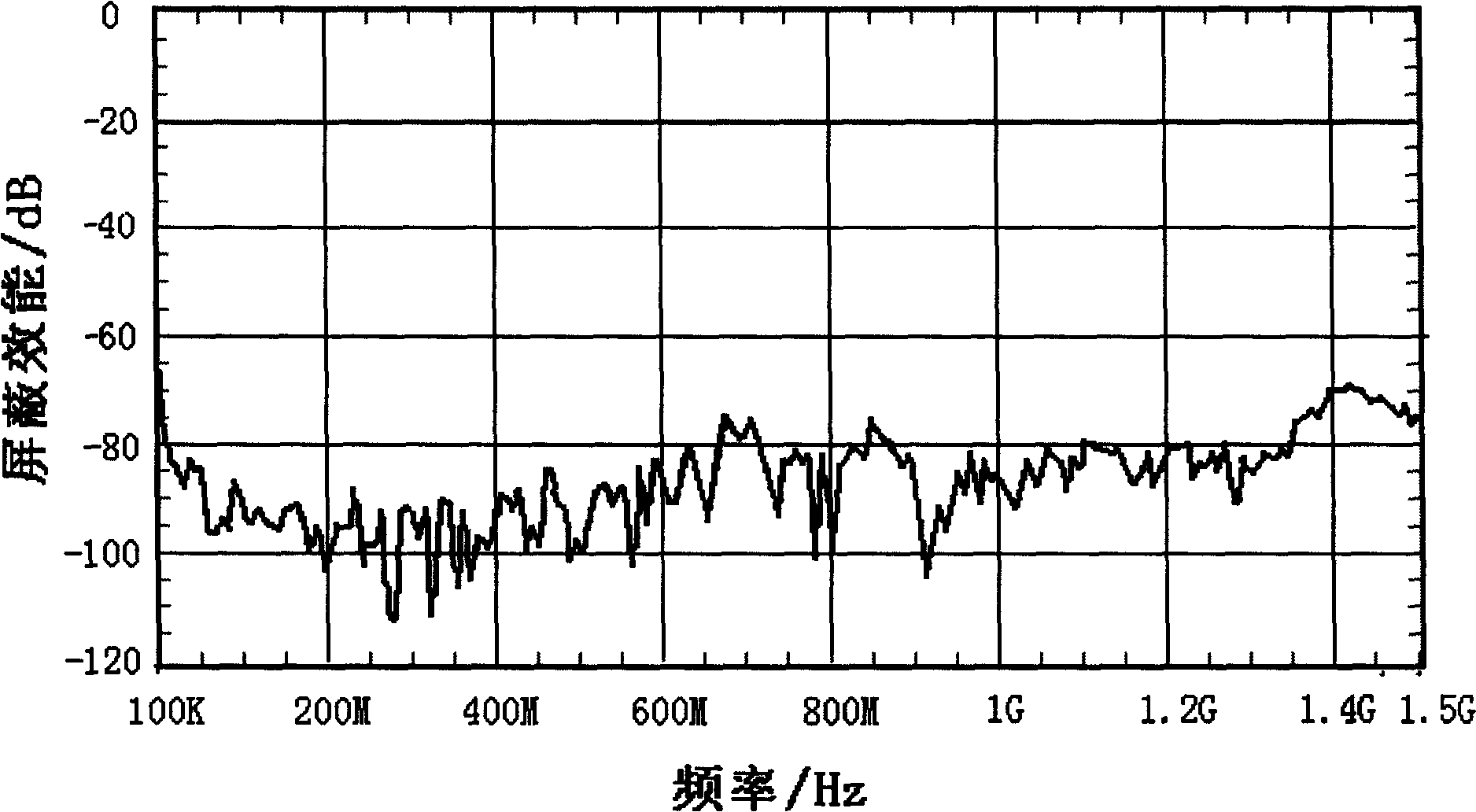

[0029] Example 2: 10 μm thick copper foil is glued to 3mm thick medium density fiberboard, using epoxy resin E-51 as adhesive, polyamide resin 650 as curing agent, the mass ratio of the two is 1:1, and the bonding pressure is 0.5 MPa, glue amount is 100g / m 2 , the hot-pressing temperature is 60° C., and the hot-pressing time is 30 minutes. The wave-absorbing plate is a single layer, the substrate is silicone rubber, and the curing agent is composed of a crosslinking agent and a catalyst. The crosslinking agent is tetraethyl orthosilicate, the catalyst is dibutyltin dilaurate, and the mass ratio of silicone rubber to curing agent is 95: 5. The mass fraction of silicone rubber and curing agent is 20%, the absorber is MnZn ferrite and carbonyl iron powder, the mass fraction of absorber is 80%, of which MnZn ferrite is 70%, carbonyl iron is 10%, The thickness of the absorber is 2mm. The wave-absorbing sheet is glued to the wood board, using epoxy resin E-51 as adhesive, polyamid...

Embodiment 3

[0030] Example 3: 20 μm thick copper foil is glued to 5mm thick medium density fiberboard, epoxy resin E-51 is used as adhesive, polyamide resin 650 is used as curing agent, the mass ratio of the two is 1:1, and the bonding pressure is 1MPa , glue amount is 200g / m 2 , the hot-pressing temperature is 60°C, and the hot-pressing time is 60min. The wave-absorbing plate is a single layer, the substrate is silicone rubber, and the curing agent is composed of a crosslinking agent and a catalyst. The crosslinking agent is tetraethyl orthosilicate, the catalyst is dibutyltin dilaurate, and the mass ratio of silicone rubber to curing agent is 95: 5. The mass fraction of silicone rubber and curing agent is 20%, the absorber is MnZn ferrite and carbonyl iron powder, the mass fraction of absorber is 80%, of which MnZn ferrite is 50%, carbonyl iron is 30%, The thickness of the absorber is 3mm. The wave-absorbing sheet is glued to the wood board, using epoxy resin E-51 as adhesive, polyami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com