Preparation method for concave-convex stick clay soil/polyacrylamide composite adsorption agent

A technology of attapulgite clay and composite adsorption, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of long cycle, complicated preparation steps, obstacles, etc., and achieves the effects of fewer preparation steps, low preparation cost, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

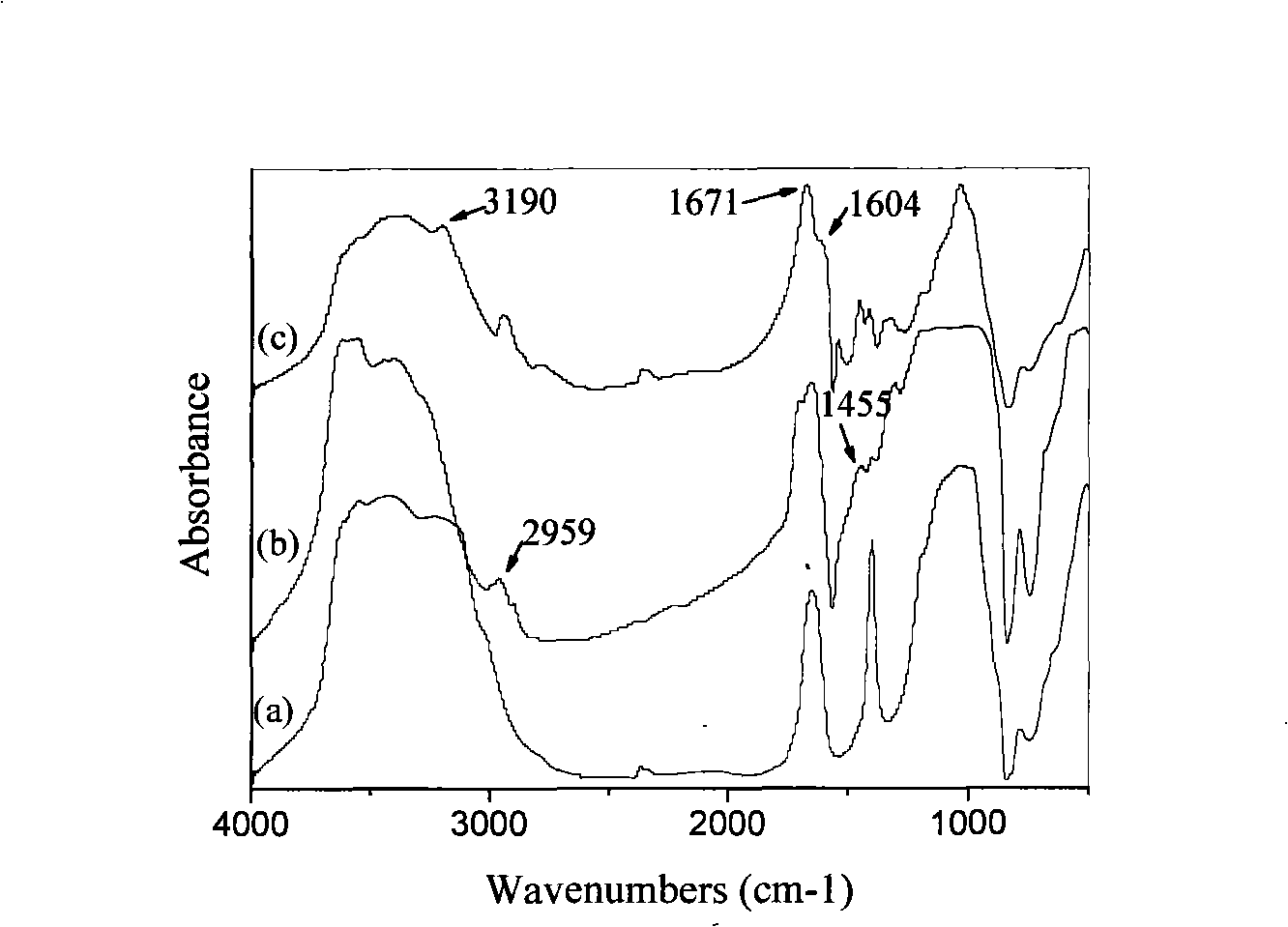

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: prepare composite adsorbent according to the following steps:

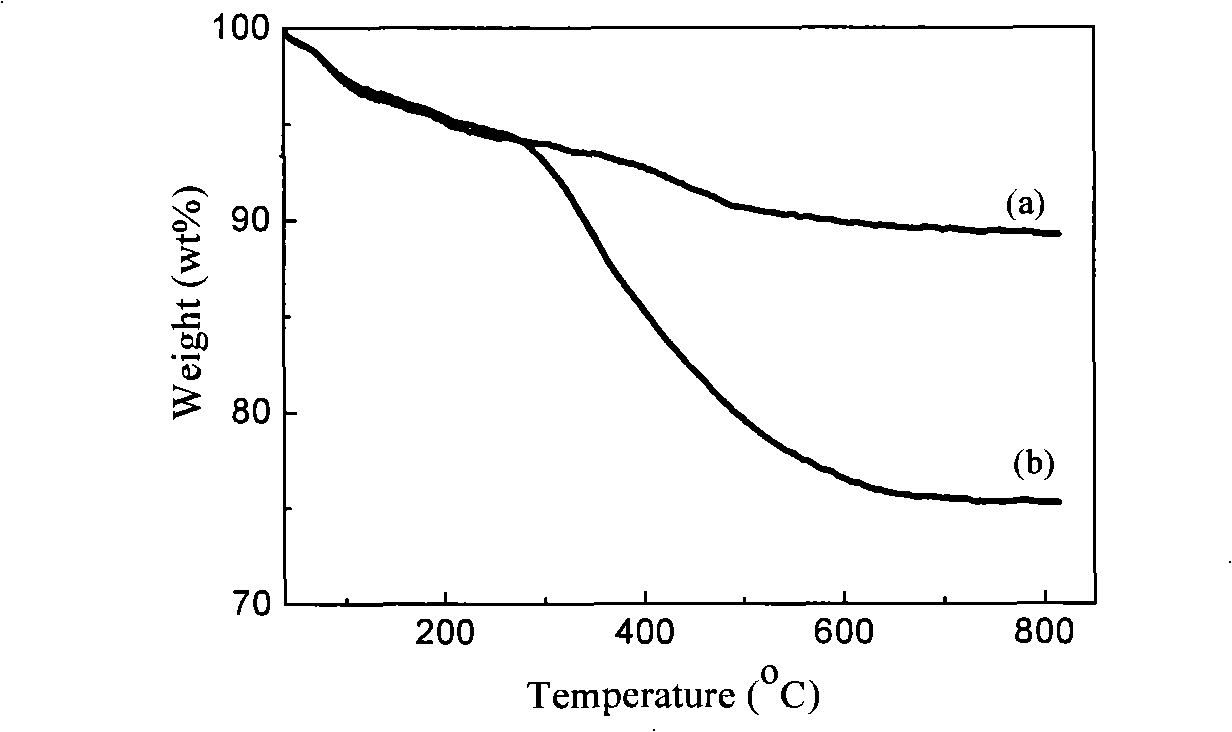

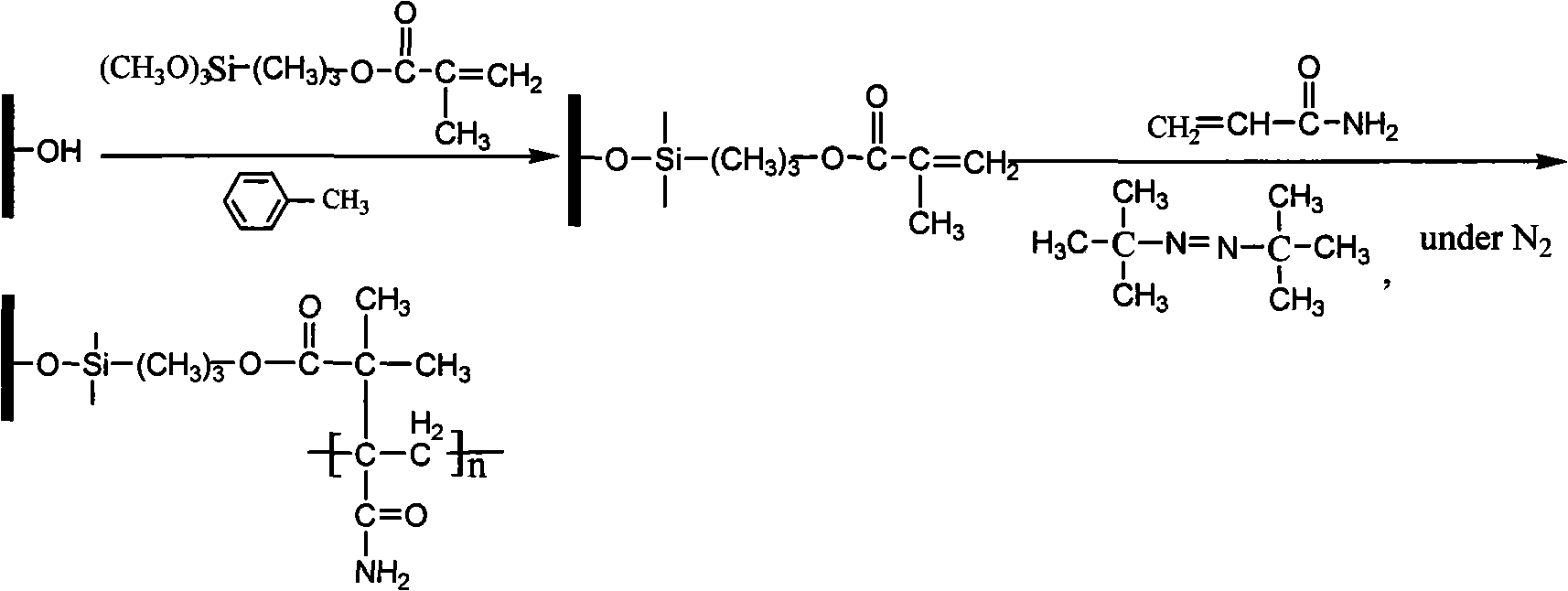

[0027] ①Dry the attapulgite clay at 105°C to constant weight, crush it through 200 meshes; put 3.0 g of the dried attapulgite clay in a beaker, add 1.0 mL of distilled water and 50.0 mL of toluene successively, and drop 1.0 mL of it under magnetic stirring γ-(Methacryloyloxy)propyltrimethoxysilane was reacted in ultrasonic waves at 30°C for 30 minutes; reacted in a magnetic stirring constant temperature oil bath at 40°C for 3 hours; the reaction product was washed with toluene and absolute ethanol successively Wash with deionized water three times, bake at 105°C to constant weight, and grind to 200 mesh to obtain modified attapulgite clay;

[0028] ② Dissolve 2.0 grams of modified attapulgite clay in 50 mL of toluene in a container, add 0.3 grams of acrylamide and 0.05 grams of azobisisobutyronitrile successively under nitrogen protection conditions, and stir in a constant temperature oil at 6...

Embodiment 2

[0029] Embodiment 2: prepare composite adsorbent according to the following steps:

[0030] ①Dry the attapulgite clay at 105°C to constant weight, crush it through 200 meshes; put 4.0 grams of dried attapulgite clay in a beaker, add 1.5mL of distilled water and 100mL of toluene successively, and drop 3.0mL of γ-(methacryloyloxy)propyltrimethoxysilane was reacted in 40°C ultrasonic wave for 40 minutes; it was reacted in a 40°C magnetic stirring constant temperature oil bath for 4 hours; the reaction product was successively washed with toluene, absolute ethanol and Wash with deionized water three times, bake at 105°C to constant weight, and grind to 200 mesh to obtain modified attapulgite clay;

[0031] ② Dissolve 2.0 grams of modified attapulgite clay in 100 mL of toluene in a container, add 1.1 grams of acrylamide and 0.125 grams of azobisisobutyronitrile successively under the condition of nitrogen protection, and stir in a constant temperature oil bath with magnetic force a...

example 3

[0032] Example 3: Prepare composite adsorbent according to the following steps:

[0033] ①Dry the attapulgite clay at 105°C to constant weight, crush it through 200 meshes; put 5.0 g of the dried attapulgite clay in a beaker, add 2.0 mL of distilled water and 150 mL of toluene successively, and drop in 5.0 mL of γ-(Methacryloyloxy)propyltrimethoxysilane was reacted in ultrasonic waves at 50°C for 50 minutes; it was reacted in a magnetic stirring constant temperature oil bath at 60°C for 5 hours; the reaction product was washed with toluene, absolute ethanol and Wash with deionized water three times, bake at 105°C to constant weight, and grind to 200 mesh to obtain modified attapulgite clay;

[0034] ② Dissolve 2.0 grams of modified attapulgite clay in 500 mL of toluene in a container, add 2.0 grams of acrylamide and 0.2 grams of azobisisobutyronitrile successively under the condition of nitrogen protection, and stir in a constant temperature oil at 100 ° C. Reaction in the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com