Adsorption and magnetic separation coupling method for recycling precious metal ion in precious metal

A precious metal and metal ion technology, applied in the field of precious metal ion recovery, can solve the problems of low mechanical strength, difficult separation, small size of biological particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

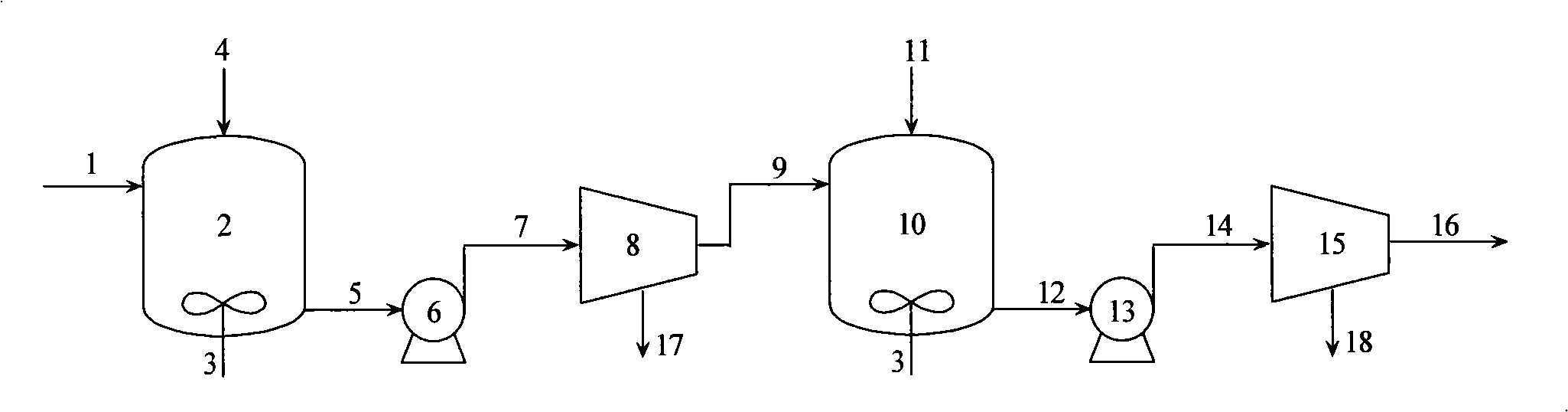

Method used

Image

Examples

Embodiment 1

[0046] Example of detection of adsorption effect of magnetotactic bacteria MTB-3 (Magnetotactic Bacterium) on a single precious metal ion.

[0047] First, pour the prepared 50mL solution containing 80mg / L single precious metal ion into the adsorber, adjust the pH value of the solution, then add MTB-3 to prepare a wet bacterial concentration of 10g / L, and seal it with a cotton plug. Close the feeding port, and keep the temperature at 25°C for 1 hour in a constant temperature refrigerated shaker. Subsequently, sampling 10ml is filtered through microporous filter membrane (aperture 0.22 μm), uses HITACHI (Hitachi) 180-80 type atomic absorption spectrophotometer to measure the content of precious metal ion, and the specific adsorption effect of measuring is as shown in table 1:

[0048] Table 1 The adsorption effects of MTB-3 cells on various metal ions

[0049] Metal ion

Au 3+

PD 2+

Ag +

Pt 4+

Cu 2+

Ni 2+

initial pH

2 ...

Embodiment 2

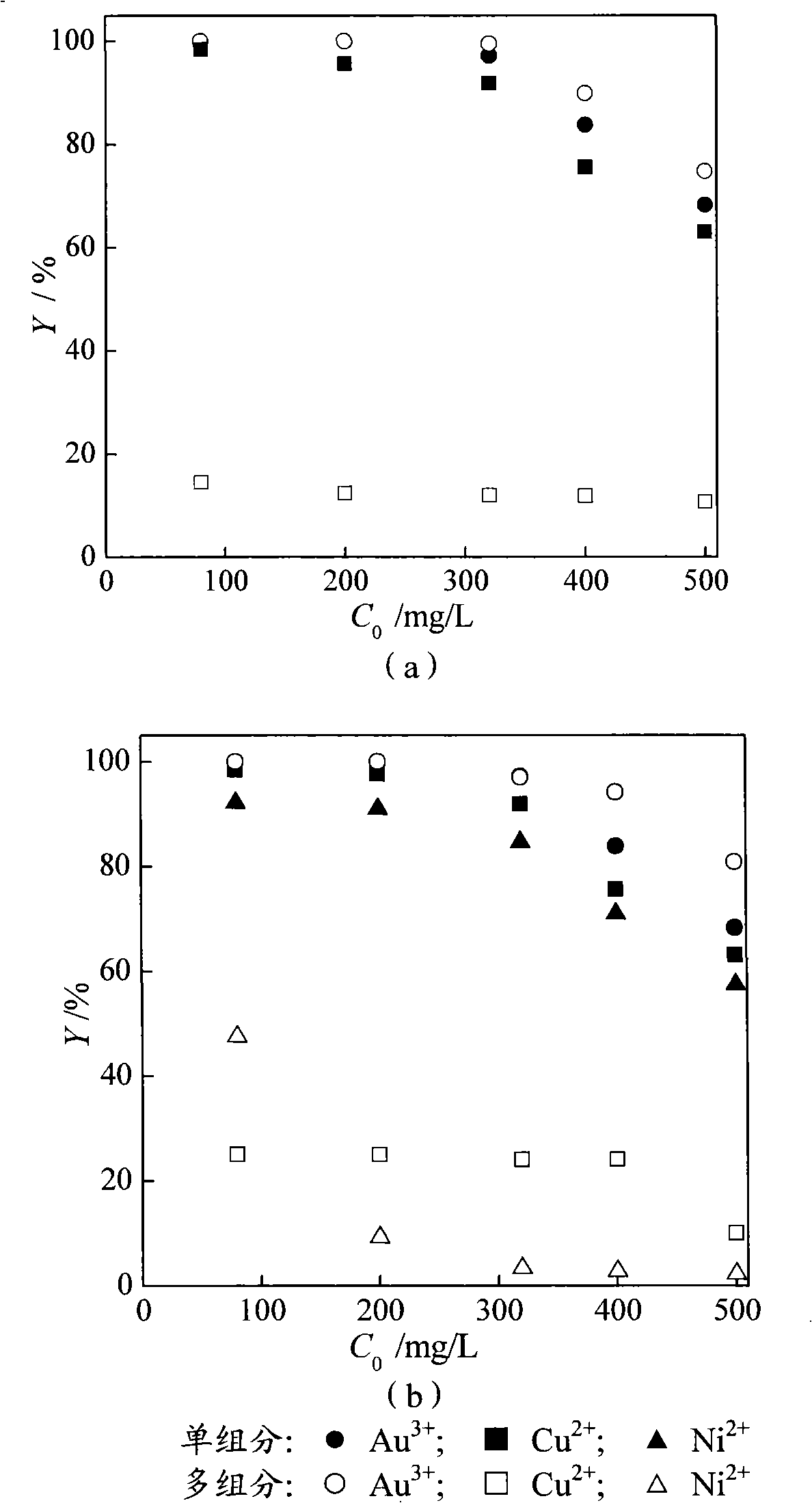

[0055] Example of the detection of the competitive adsorption characteristics of MTB-3 bacteria to the coexistence system of various metal ions.

[0056] According to the experimental method described in the above-mentioned embodiment one, carried out containing Au 3+ 、Cu 2+ and Ni 2+ Adsorption experiments of two-component and three-component systems. Specifically, 50 mL of a solution containing 80 mg / L of a single precious metal ion or 80 mg / L of multiple metal ions is prepared in the adsorber each time.

[0057] For a single Au ion solution, adjust its pH value to 2; for a solution containing two components of Cu and Ni, adjust its pH value to 5; and for a solution containing three components of Au, Cu, and Ni, adjust its pH value to 2. Then add magnetotactic bacterium MTB-3, prepare it to a wet bacterial concentration of 10g / L, seal the feeding port with a cotton plug, and keep the temperature at 25°C for 1 hour in a constant temperature refrigerated shaker. see fig...

Embodiment 3

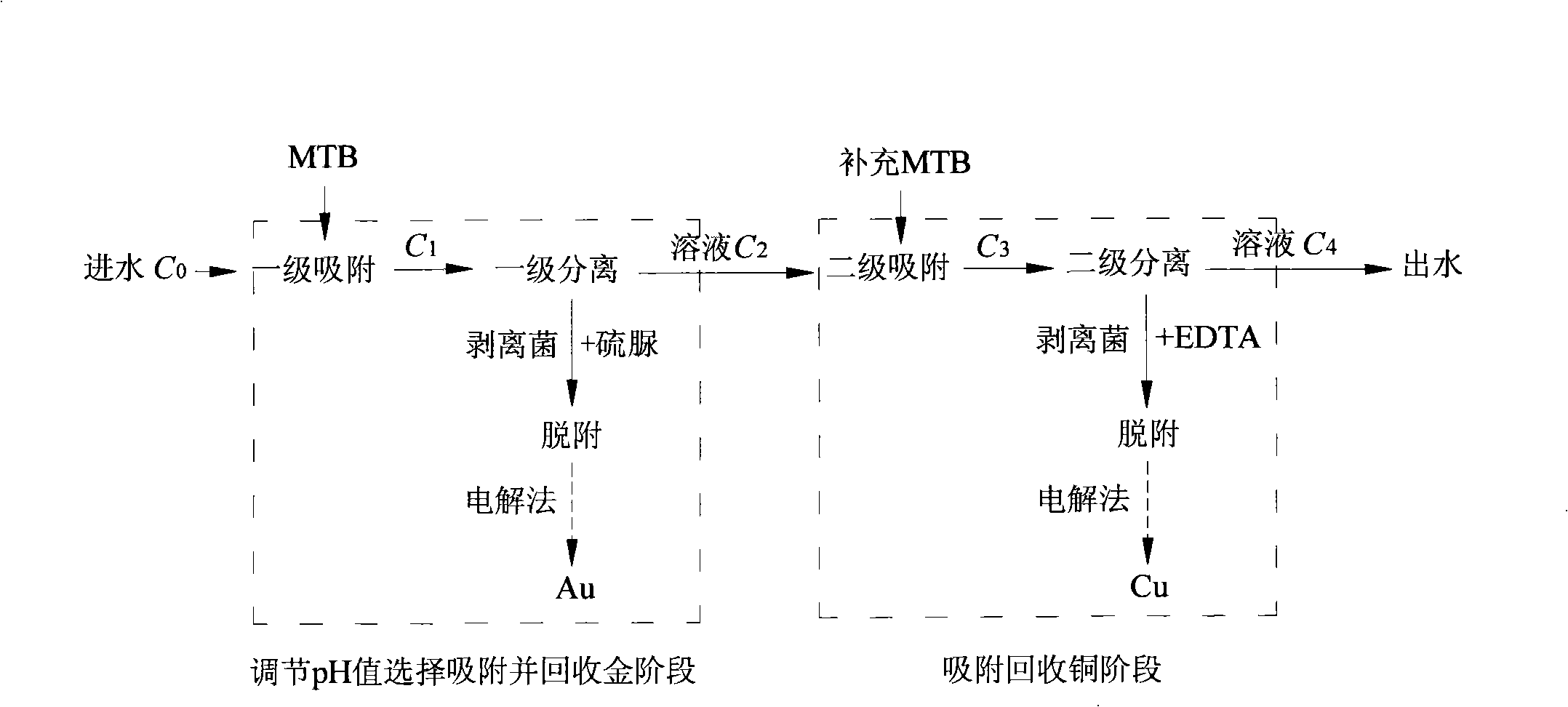

[0060] The specific embodiment of the adsorption recovery process taking gold and copper two kinds of precious gold ions as examples.

[0061] containing Au 3+ -Cu 2+ In the two-component solution, the pH value of the solution was adjusted to 2, and the magnetotactic bacteria MTB-3 on Au 3+ The adsorption amount is the largest, while for Cu 2+ The adsorption amount of is suppressed; if the pH value is adjusted to 5, the Cu 2+ maximum adsorption capacity. Therefore, proposed methods including adjusting the pH value to selectively adsorb metal ions Au 3+ And recovery of gold, adsorption of metal ions Cu 2+ And recover copper two-stage adsorption and magnetic separation coupling technology.

[0062] See the specific process image 3 , image 3 It is a schematic diagram of the process flow of the adsorption magnetic separation coupling method taking gold and copper as examples of two precious metals, image 3 Medium, C 0 Refers to the initial concentration of metal ions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com