Method for preparing biological diesel oil with methyl acetate act acyl acceptor

A technology of methyl acetate and biodiesel, which is applied in the preparation of liquid hydrocarbon mixtures, biofuels, and biological raw materials, and can solve problems such as complex technologies, toxicity, and shortened service life of enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

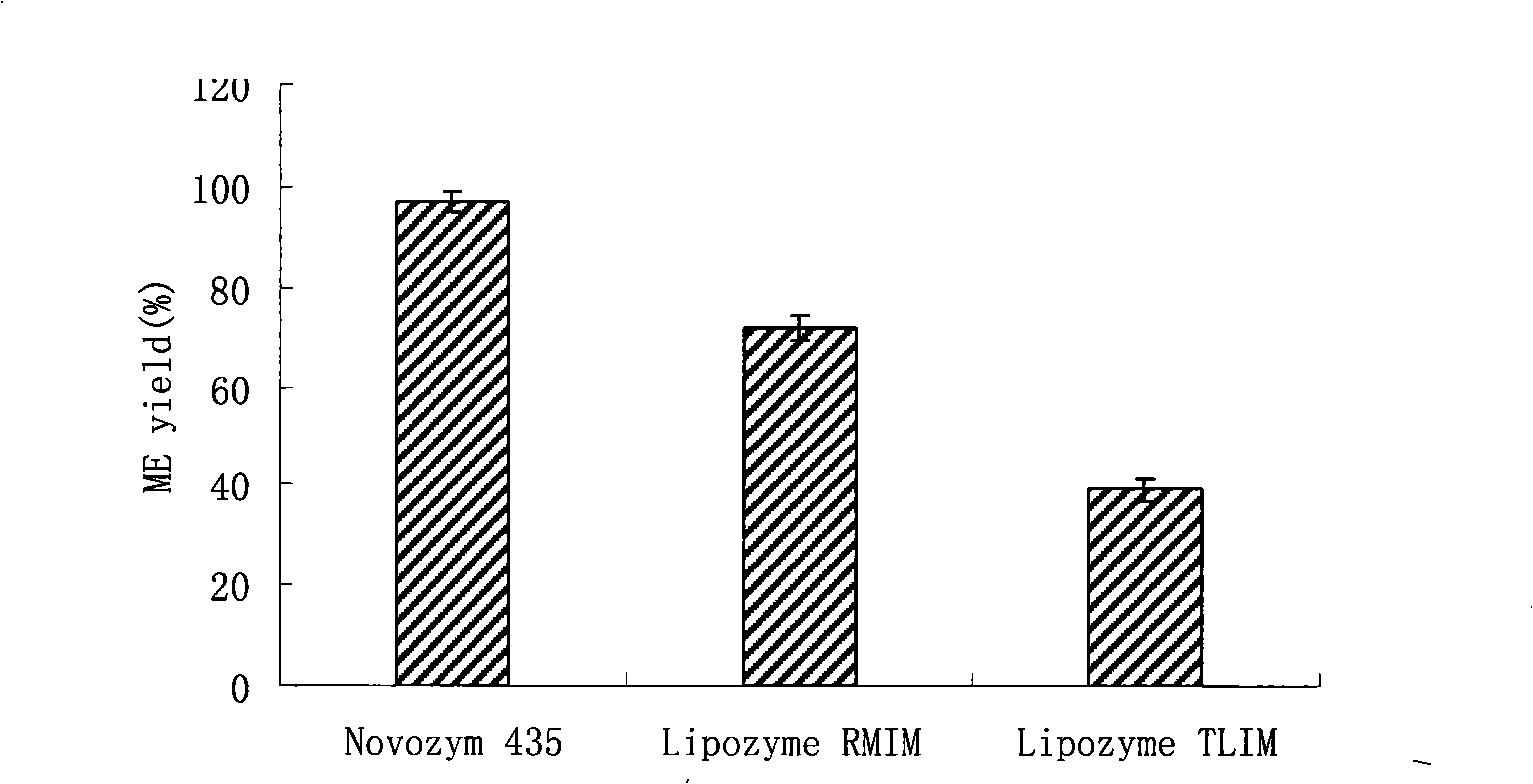

[0041] Comparison of immobilized lipase catalyzed transesterification reaction of refined cottonseed oil when different refined cottonseed oil was used to prepare biodiesel:

[0042] In order to select the most suitable immobilized lipase for catalyzing the transesterification reaction of refined cottonseed oil, we selected Novozym435, Lipozyme TLIM and Lipozyme RMIM three different immobilized lipases for comparison. Add refined cottonseed oil 8.699g (0.01mol) in 50ml tool stopper conical flask, 30% lipase (mass fraction), the mol ratio of methyl acetate and refined cottonseed oil is 14: 1, 200rpm, 40 ℃, reaction 14 hours, such as Picture 1-1 As shown, the methyl ester yield of refined cottonseed oil catalyzed by Novozym435 was 97%, and the yield of methyl ester catalyzed by LipozymeRMIM and Lipozyme TLIM was only 72% and 39%. This shows that among the above three lipases, Novozym435 is more suitable as a catalyst for the preparation of biodiesel.

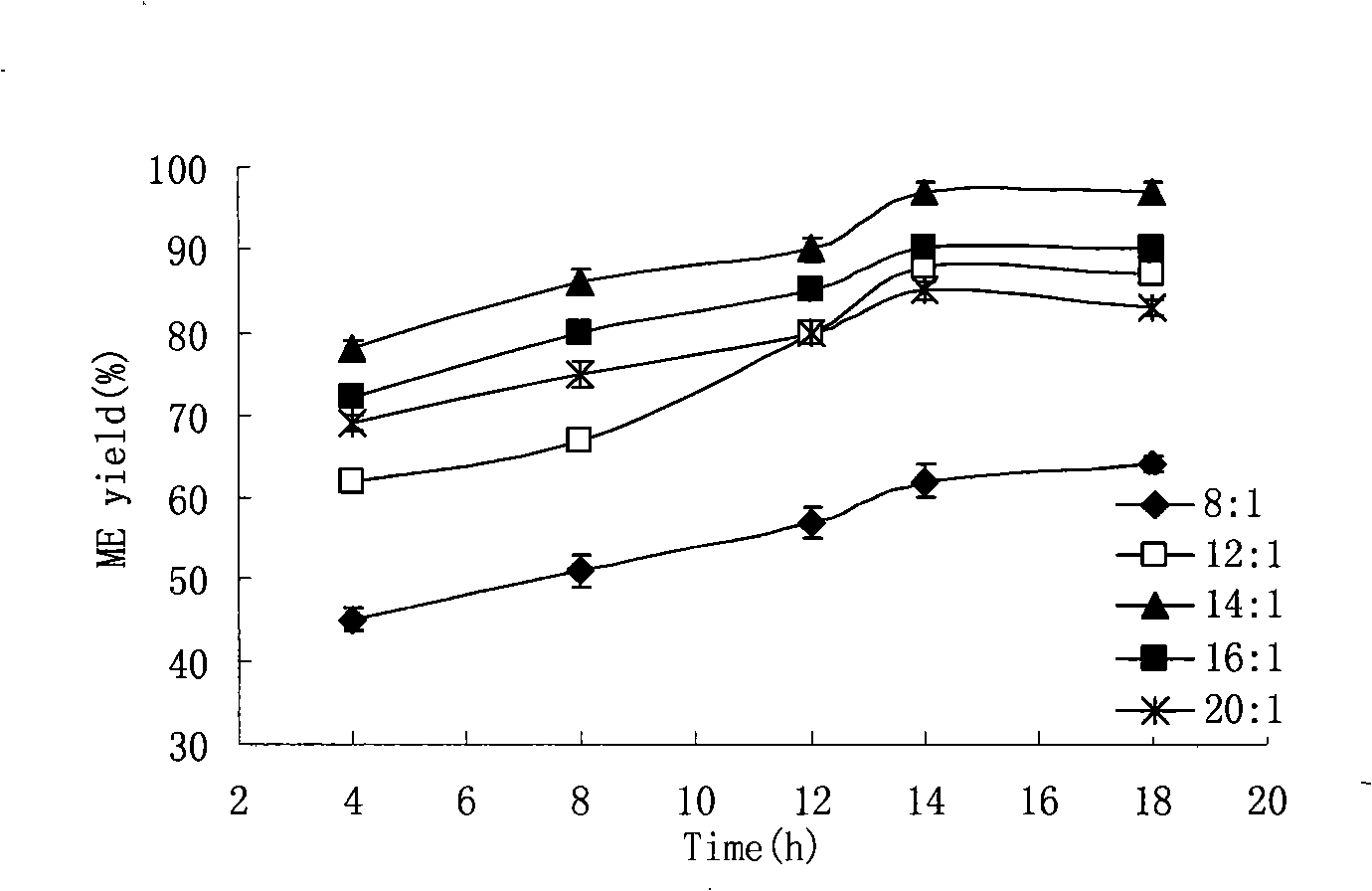

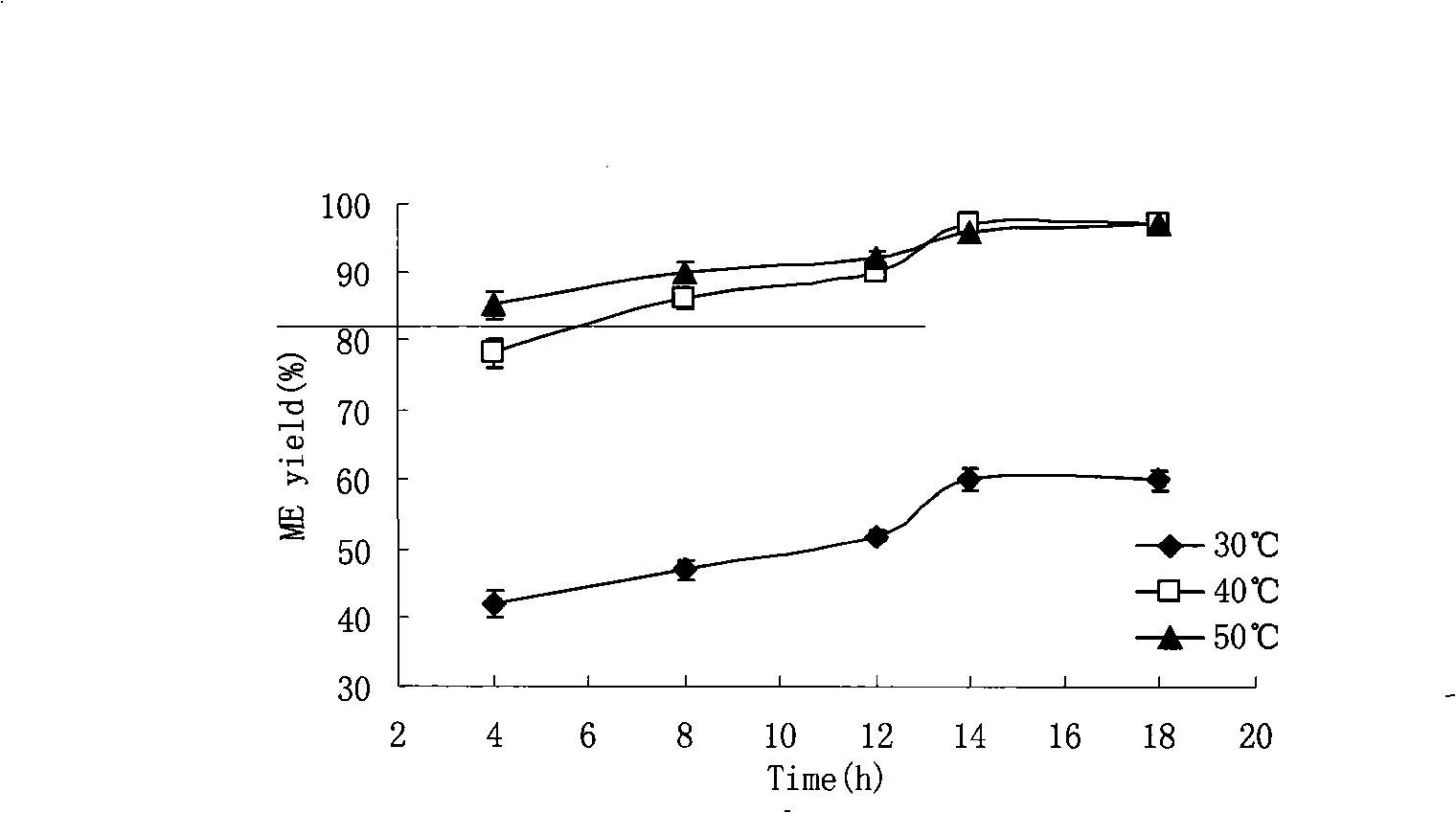

[0043] Effects of Differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com