Film distillation backheating absorption type refrigerator

A refrigeration device and membrane distillation technology, applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problem of reducing the thermal performance of lithium bromide absorption refrigeration units, failure of high-temperature solution surfactants and corrosion inhibitors, and high-temperature solution corrosion To achieve the effect of simplifying the refrigeration equipment, improving the refrigeration coefficient and improving the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the technical solutions of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings and embodiments.

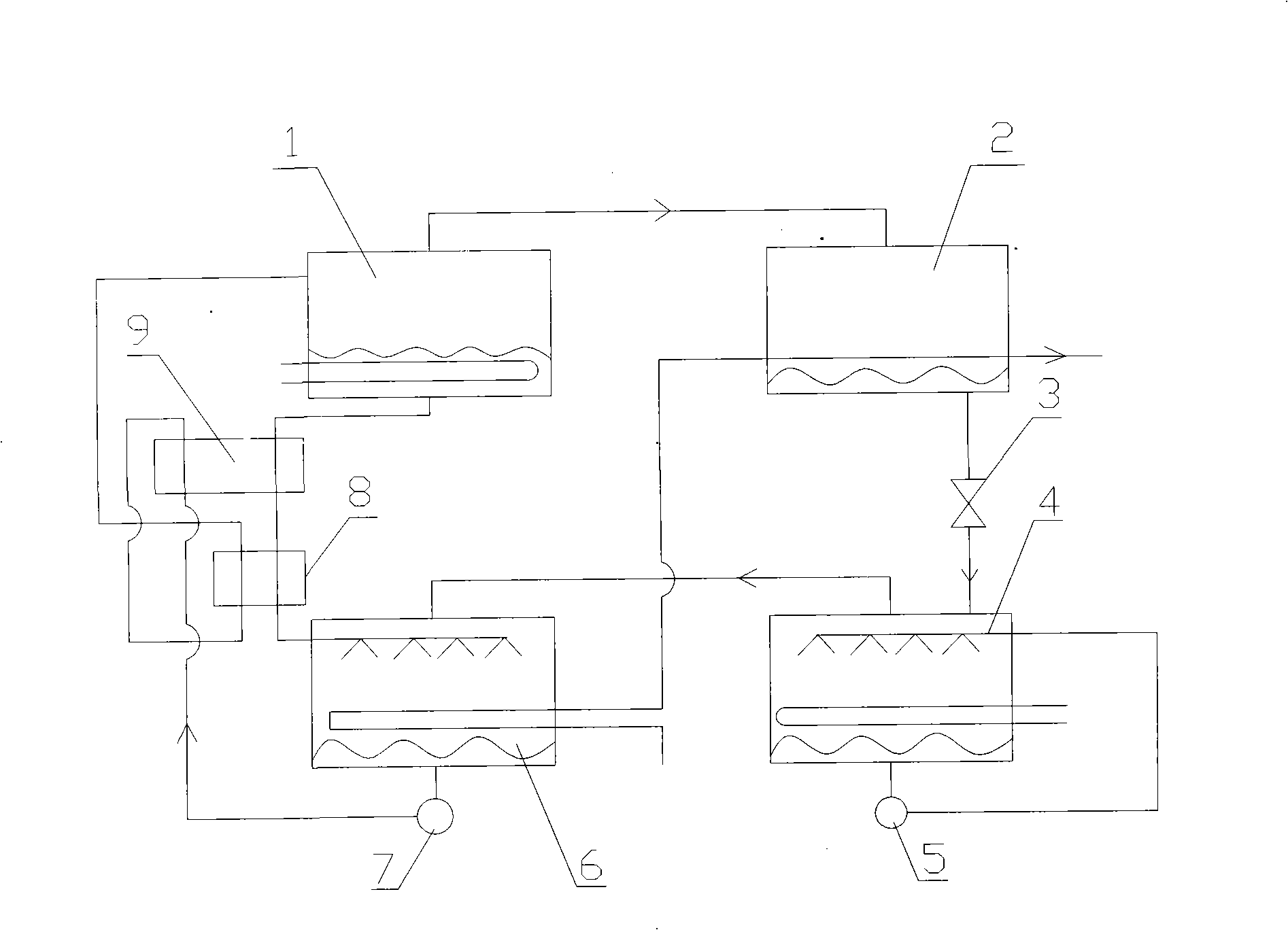

[0030] Such as figure 1 As shown, a membrane distillation heat recovery absorption refrigeration device consists of a generator 1, a condenser 2, a throttling device 3, an evaporator 4, a refrigerant pump 5, an absorber 6, a solution pump 7 and a solution heat exchanger 8 In the configuration, a membrane distillation mass transfer heat exchanger 9 is installed between the generator 1 and the solution heat exchanger 8, and the membrane distillation mass transfer exchanger 9 communicates with the generator 1 and the solution heat exchanger 8 through pipelines. The bottom of the generator 1 is sealed and installed with pipelines. After the pipeline passes through the membrane distillation mass transfer heat exchanger and the solution heat exchanger, the end of the pipeline is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com