Composite electroosmosis and AC electric shock water drain method and uses thereof

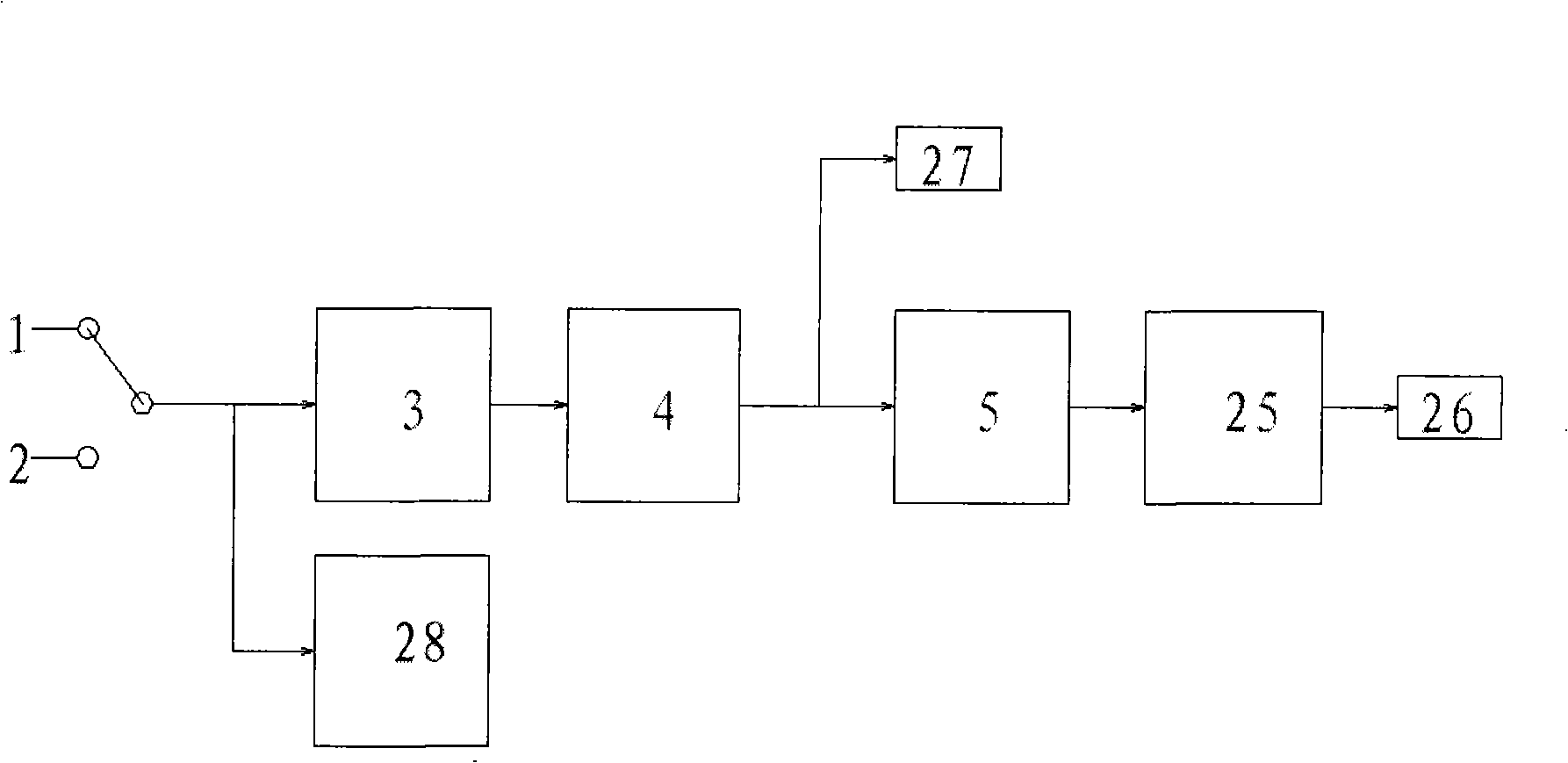

A technology of electroosmosis and electric shock meter, which is applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as gaps, shorten the construction period, improve the comprehensive benefits of the project, and improve the seepage capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

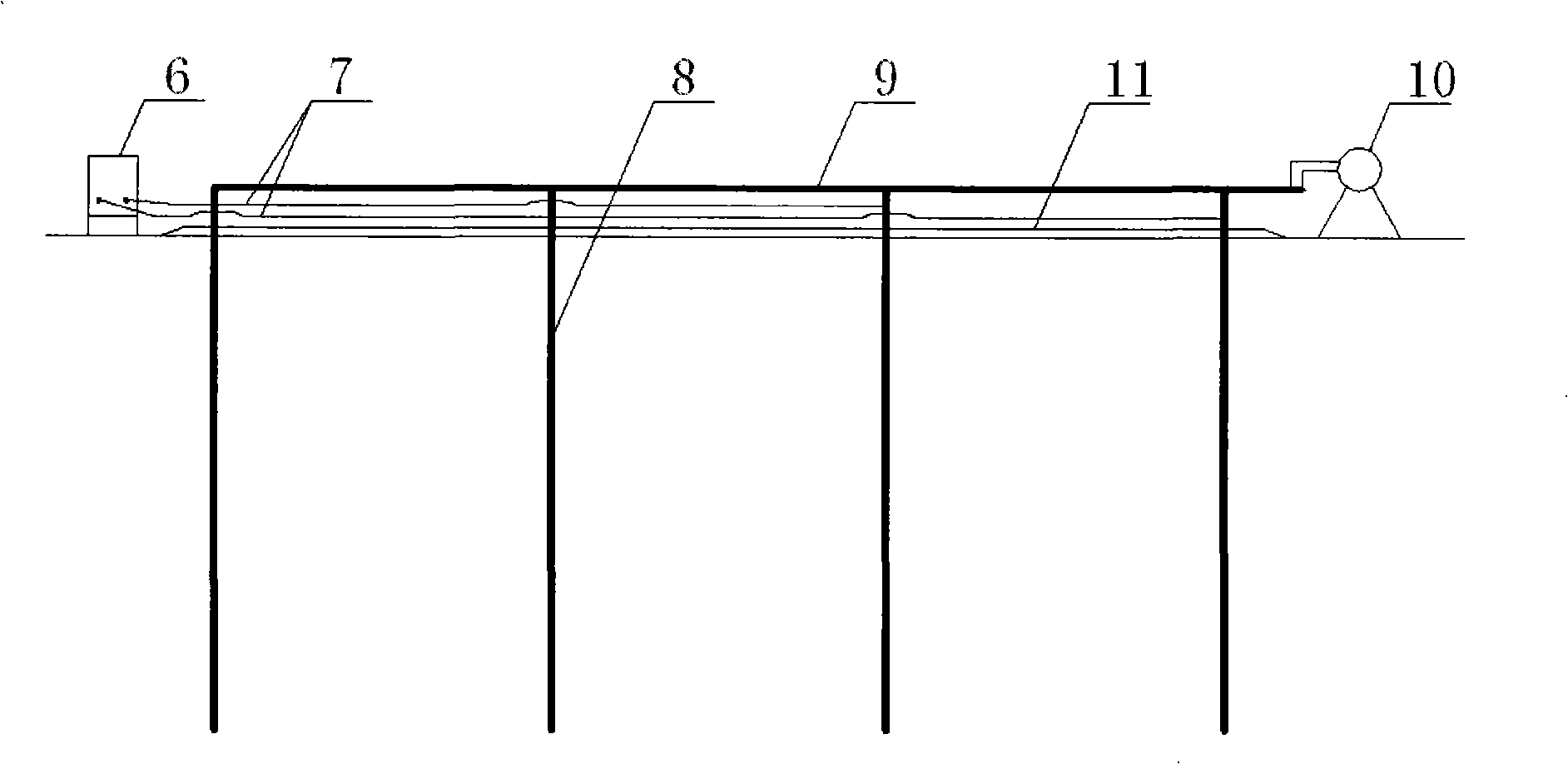

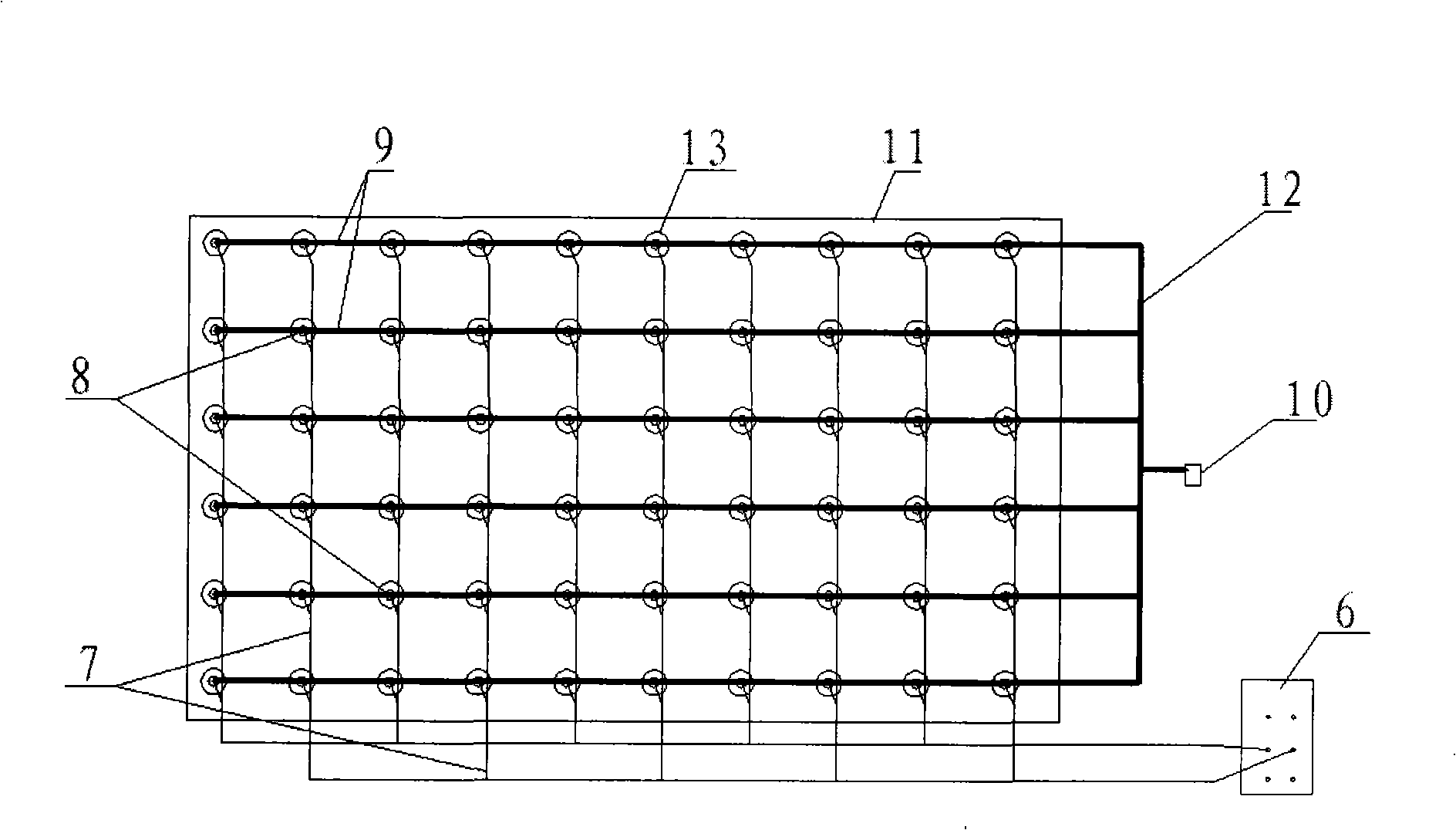

[0060] In a test site in Zhejiang, the soft soil foundation was reinforced, with an area of 1,000 square meters and a treatment depth of 8 meters. See figure 2 , image 3 .

[0061] 1. Preparations before compound electroosmosis and AC electric shock drainage:

[0062] a. Level the site, remove sharp objects, and carry out the construction lofting of the composite pipe 8 on the flat surface according to the mesh distribution of the mesh hat hole vacuum film 11, such as image 3 As shown, the mesh spacing is set to 1 meter.

[0063] b. Preparation of mechanical equipment and materials: including mesh hat hole vacuum film 11, vacuum pump 10, electric shock meter 6, composite pipe 8, horizontal drain pipe 9, water collection pipe 12, etc.

[0064] c. Layout of composite pipes: such as figure 2 , image 3. ①Use a water gun to form holes according to the mesh position of the membrane; ②Then sink a sand column bag with a certain length of sand into the hole; ③Insert a comp...

Embodiment 2

[0073] In a test base in Guangdong, the silt reconstituted soil was treated with the trough as the carrier. The trough is 12 meters long, 4 meters wide and 2 meters high. See attached Figure 4 .

[0074] 1. Preparatory work:

[0075] a. Insert a group of composite pipes 8 in the tank, and arrange electrode nets 18 and percolation devices 14 on the four walls of the tank body 15; then put the sludge into the tank, and the mud surface is flush with the slot opening.

[0076] b. Lay the redundant film 17 with openings on the mud surface. When laying the film, reserve a certain area of redundancy at the position of each composite pipe 8, so that this redundant area wraps the outer wall of the composite pipe 8 top, and the hoop is elastically Hoop, seal the membrane 17 and the outer wall of the composite pipe 8, and then open a hole where the membrane is located on the nozzle of the composite pipe, so that the composite pipe protrudes out of the membrane, and then check the lap...

Embodiment 3

[0085] In a test base in Guangdong, the dehydration treatment of sludge fertilizer with container 20 as the carrier, the container is a hollow cylinder with a radius of 2 meters and a height of 1.5 meters, see attached Figure 5 .

[0086] 1. Preparatory work:

[0087] a. Install the electrode net 18 and the percolation device 14 on the inner surface and bottom of the top cover of the container, add the sludge into the container, cover the piston top cover, seal it to make it airtight, and apply a radius 1.8 on the top cover at the same time. The 1-meter-high concrete pier with holes in the center carries out static load on the silt.

[0088] b. Connect the horizontal drain pipe 9 with the container top cover joint 22 and the joint 23 at the bottom, and connect the horizontal drain pipe 9 with the vacuum pump 10 .

[0089] c. The electrode net connector 19 and the composite pipe 8 are connected to the electroosmotic shock instrument 6 through the energizing line 7 .

[0090...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com